The quality of bearings depends on the fit clearance value meeting the process design specifications. The key to achieving compliant clearance values and producing high-quality, high-precision bearings lies in the fit compatibility meeting the clearance value process specification requirements.

The clearance value refers to the relative displacement between the inner and outer rings of a bearing, specifically the size of the clearance between various components inside the bearing under certain conditions. The clearance value directly affects the operating accuracy, noise level, lubrication condition, and service life of the bearing.

The size of the bearing clearance value will directly affect the working life of the bearing and even the operational stability of the entire equipment; Excessive clearance may lead to increased vibration and noise, reducing load-bearing capacity; A too small clearance will increase friction, generate more heat, accelerate wear and thermal damage. So, the primary goal in bearing manufacturing and assembly is to achieve the required clearance range for the combination of the inner and outer rings and rolling elements of the bearing.

ZQMES provides a set of intelligent fitting modules embedded in MES for bearing enterprises, which will solve the assembly and fitting of different types of bearings, and how the manufacturing and production departments can perform ring fitting and fitting to meet the clearance value process requirements of different bearing types.

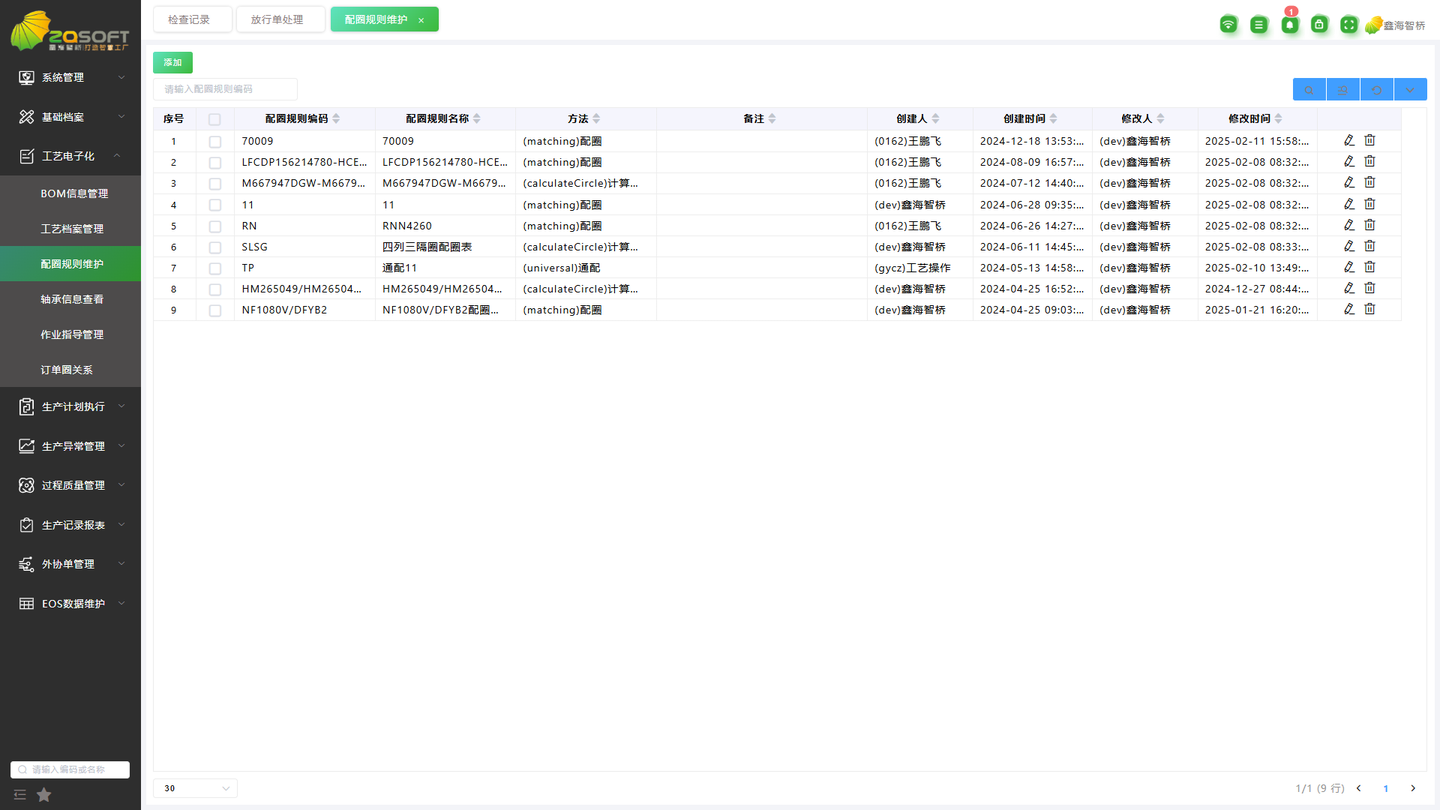

Definition of Integration Rules

By using the ZQMES ring fitting rule maintenance module, the bearing fitting rules are transformed into computer fitting logic, fully defining the calculation logic of clearance values when fitting different types of bearings. Combined with workshop work orders, the appropriate fitting rule logic is automatically called to achieve automation of fitting calculation.

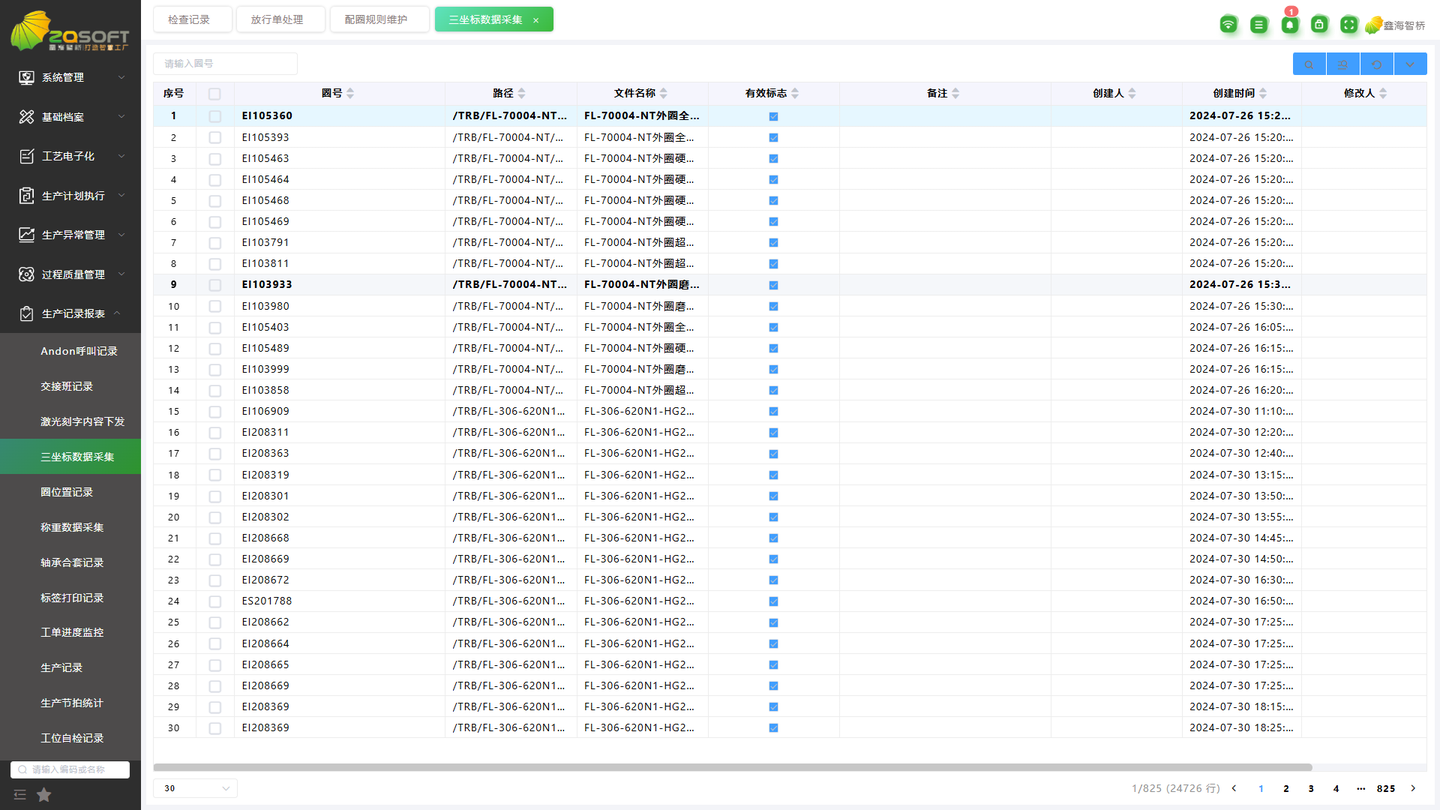

Collection of inner and outer circle dimensions

ZQMES is integrated with three coordinate equipment to obtain three coordinate detection reports, analyze the dimensional information of the inner and outer rings after processing, and form three coordinate detection records for the inner and outer rings.

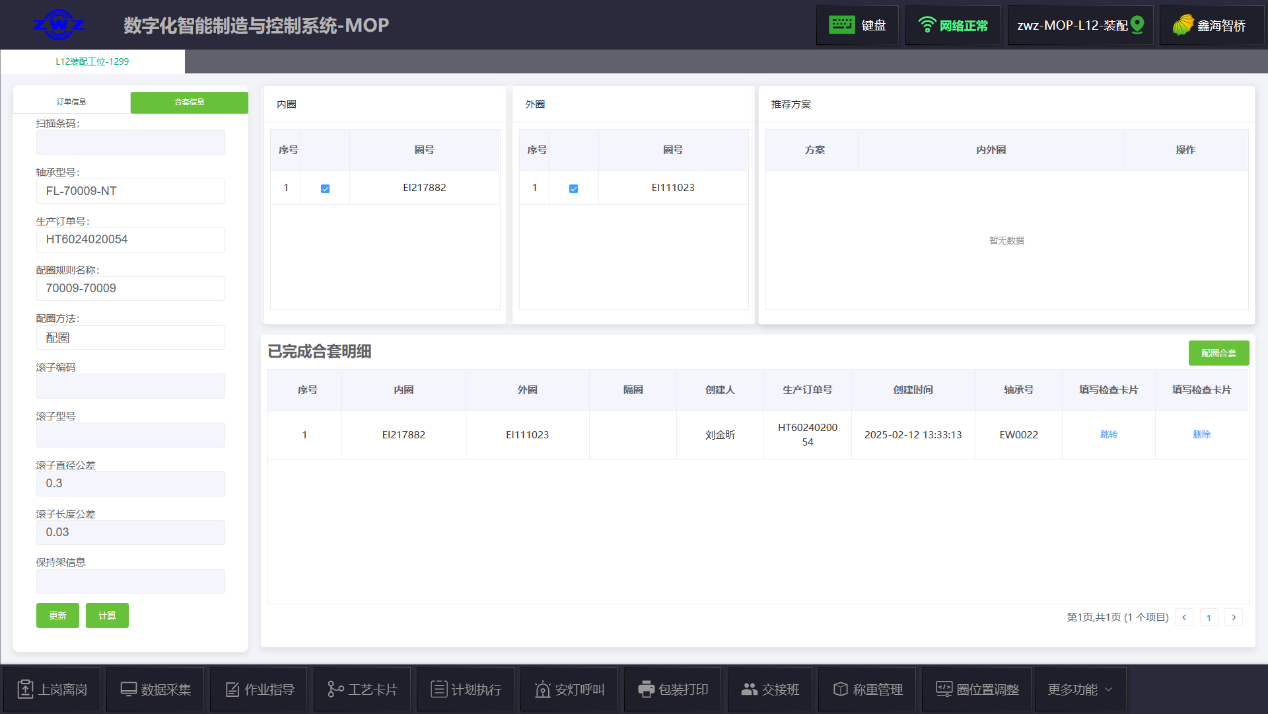

Intelligent integrated computing

ZQMES issues an assembly work order to the assembly station, automatically calls the fitting rule logic based on product information, automatically captures the calculation items of the inner and outer ring fitting logic, and divides the inner and outer ring groups according to the enterprise's requirements for bearing accuracy. The actual produced inner and outer rings are stored in groups.

Assembly and fitting instructions

By combining scanning devices on the assembly site, any inner/outer ring data can be obtained. The system automatically calculates the size of the outer/inner ring that meets the clearance value process requirements, and performs group matching to provide guidance on ring fitting, guiding operators to assemble and fit.

The intelligent fitting module of ZQMES has achieved intelligent and automated bearing manufacturing and assembly fitting, effectively improving assembly efficiency and bearing accuracy.

summarize

With the rapid development of intelligent manufacturing, enterprises are facing unprecedented opportunities and challenges. In this wave of digital transformation, how to improve production efficiency and optimize management processes through innovative technology has become an important issue that every enterprise urgently needs to solve. Intelligent manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing enterprise competitiveness.

In this context, ZQSOFT continues to provide customers with leading Internet of Things technology, intelligent manufacturing solutions, MES/MOM/APS systems, etc. with its profound technology accumulation and rich industry experience. Our solutions cover all levels from production sites to enterprise management, helping companies achieve more flexible and intelligent production modes while improving production efficiency and reducing costs.

As a technology leader in the industry, ZQSOFT has continuously promoted the deep integration of digital transformation and intelligent manufacturing, and is committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of "innovation driven, intelligent manufacturing", helping customers stand out in fierce market competition and stay at the forefront of industry development.

If you would like to learn more about intelligent manufacturing or explore how to improve enterprise efficiency through digital transformation, please feel free to contact us at any time. ZQSOFT will wholeheartedly provide you with all-round technical support and services, and work together with you to enter a new era of intelligent manufacturing.

1883D6D19D79454E9B3FA44C8F7F50F7.png)