The construction of smart factories has become an important means for tire companies to enhance their competitiveness. Especially Chinese tire companies have increased their investment in the field of intelligent manufacturing, building new intelligent factories to improve production efficiency and product quality, adapt to changes in market demand, and enhance market competitiveness. Automated logistics is an important component of smart factory construction.

With the continuous increase in tire demand, the intelligent transformation of domestic tire factories has accelerated in recent years, and progress and breakthroughs have been made in the following areas:

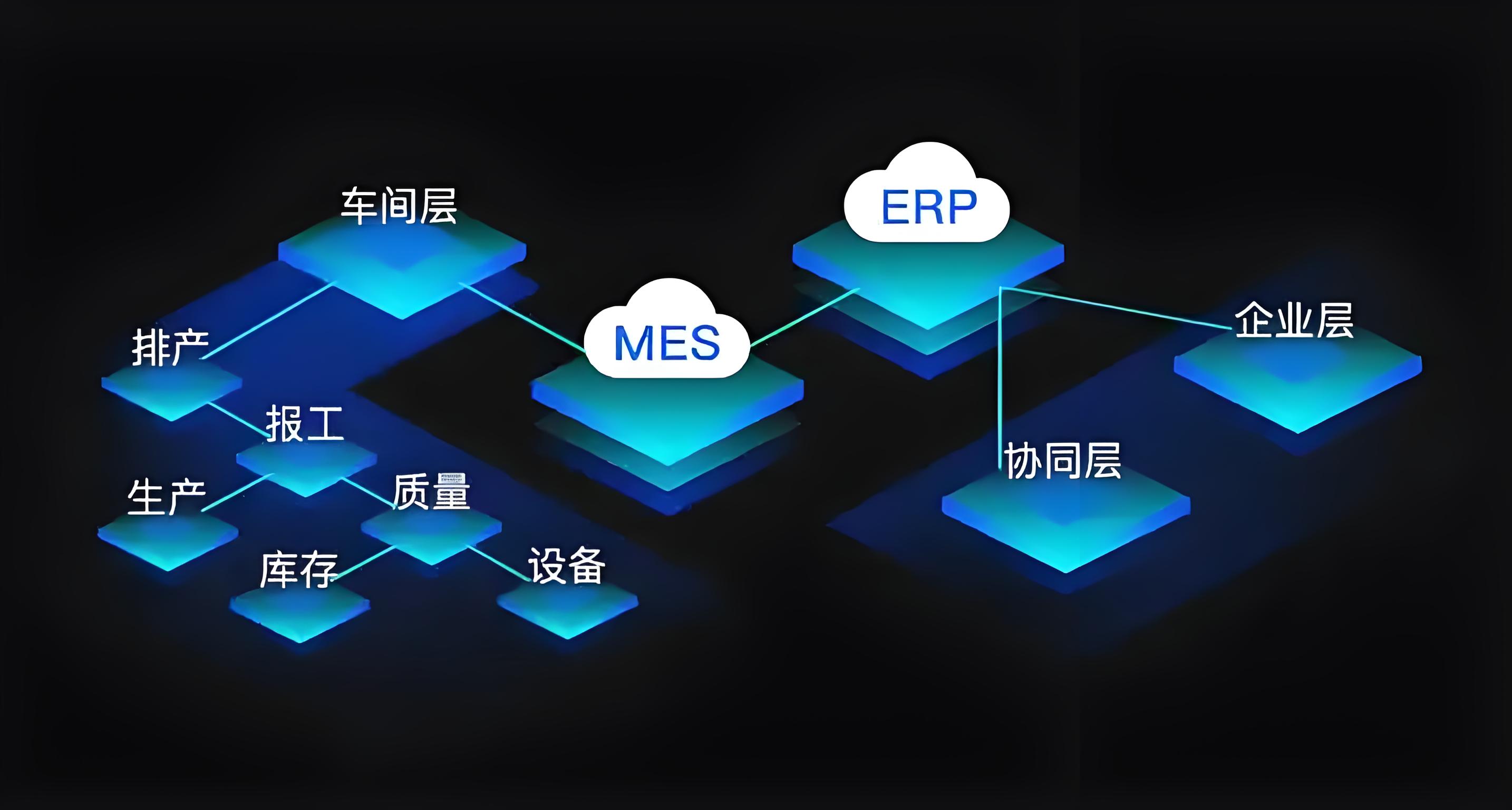

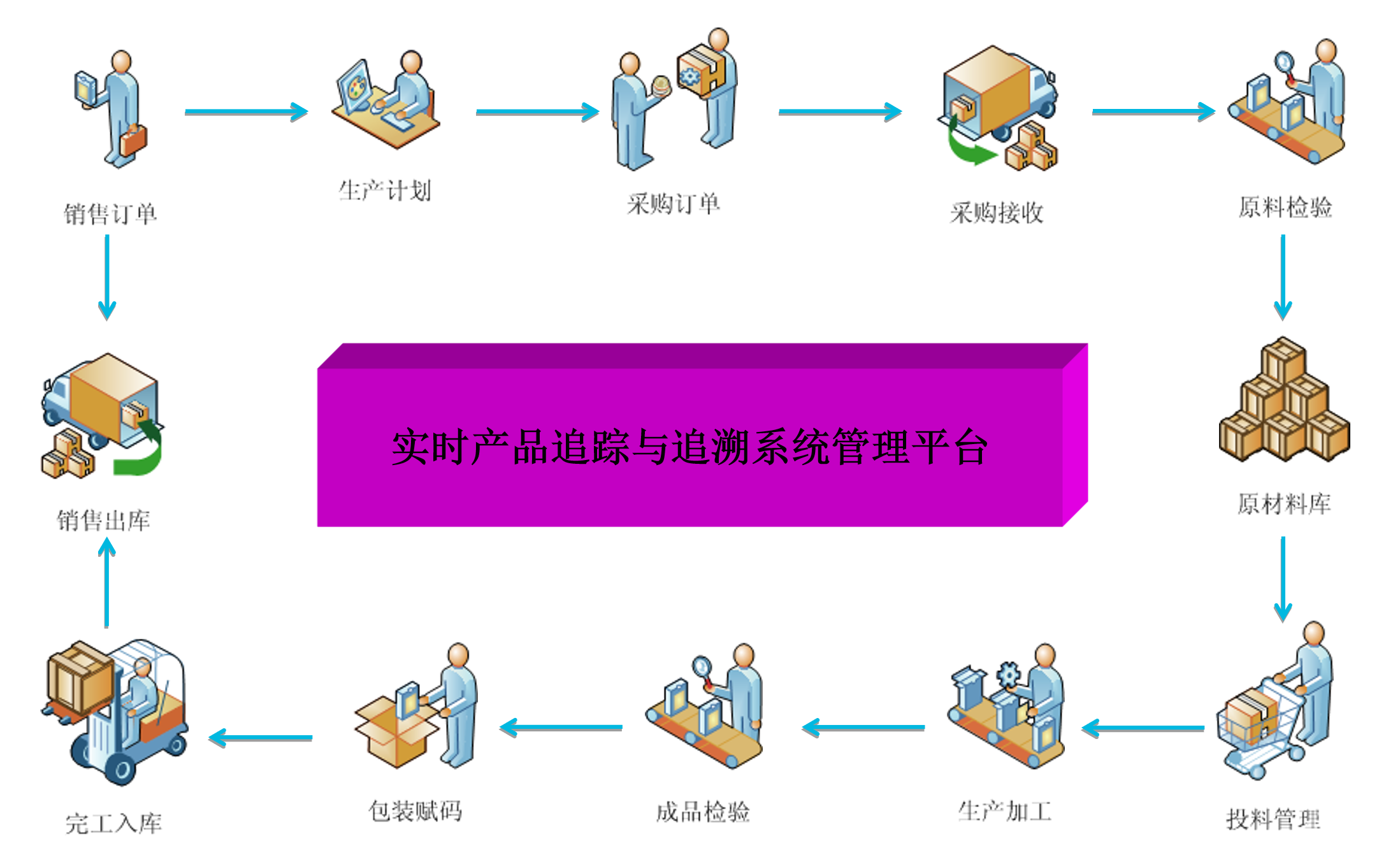

The traceability mechanism of Manufacturing Execution System (MES) is the key to ensure product quality, meet compliance requirements and improve production efficiency. The following are the methods to establish an effective traceability mechanism:

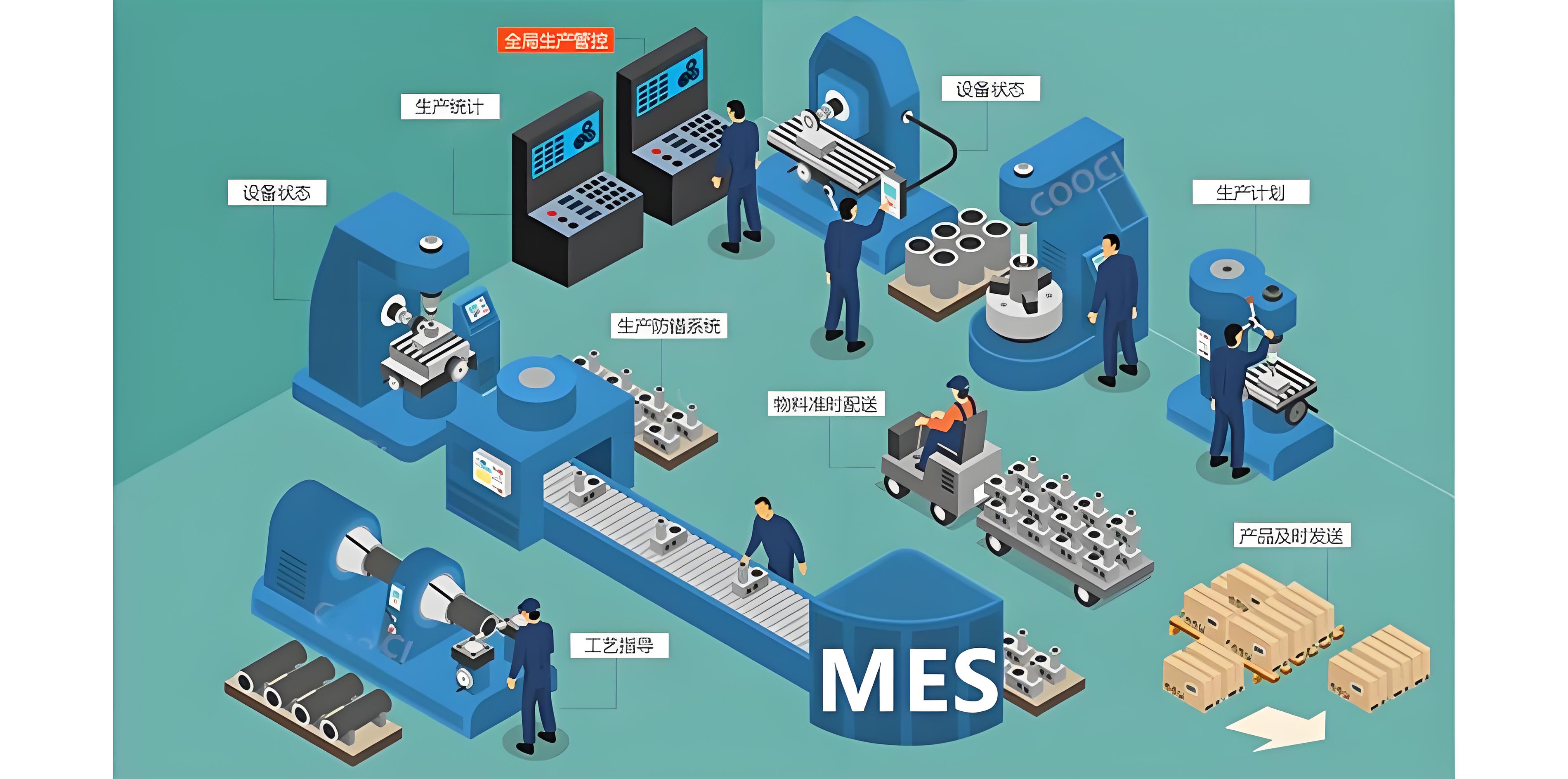

With the rapid development of smart manufacturing, enterprises are facing unprecedented opportunities and challenges. In such a wave of digital transformation, how to enhance production efficiency and optimize management processes has become an important issue that every enterprise must address. As a key driver of industrial upgrading, smart manufacturing has become an important engine for industry development and improving enterprise competitiveness.

The application of barcode technology in MES system can inject digital energy into production management, achieving precise data collection and efficient circulation through low-cost and easy to deploy information carriers. The core value and typical applications of barcodes in manufacturing scenarios are analyzed from the dimensions of full process traceability, improved operational efficiency, and strengthened quality control

The inventory function in WMS (Warehouse Management System) achieves the core value of "account physical consistency control, accurate traceability of inventory losses, and optimization of operational efficiency" through a systematic inventory data verification mechanism.

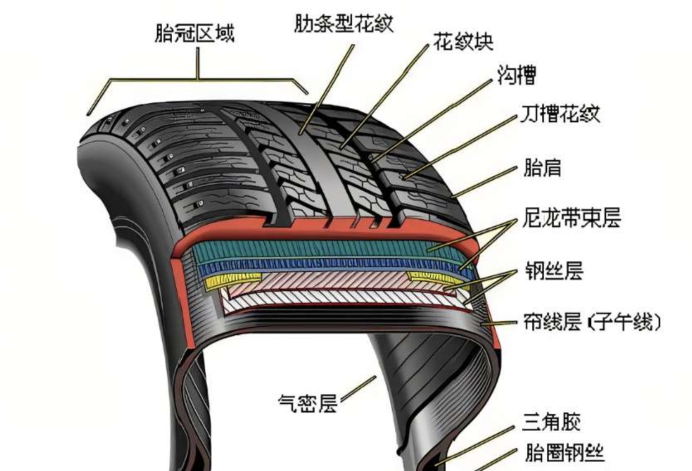

Product Data Management (PDM) plays a crucial and indispensable role in the operation system of Manufacturing Execution System (MES), and can be regarded as one of the core execution standards.It is built on a series of complex and refined foundations, including product formula research, product structure design (BOM), construction standard design, and various process flows.

The Energy Management System (FEMS) utilizes modern computer and distributed control technologies to establish a comprehensive energy consumption management platform within factories. It enables the categorized monitoring and management of energy consumption for water, electricity, and gas (compressed air, coal gas, natural gas, and steam), helping enterprises achieve cost control and energy efficiency.

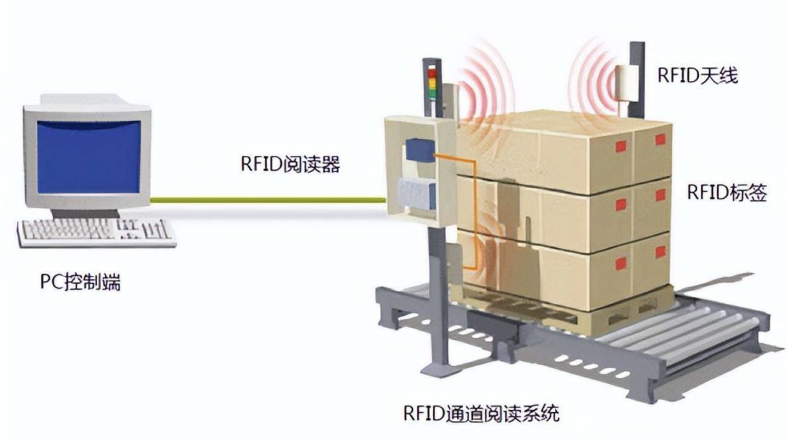

In modern manufacturing, Manufacturing Execution System (MES) plays a key role, and material information collection is one of its core functions.MES achieves precise material information collection through various technological means, providing strong support for the production process.

1883D6D19D79454E9B3FA44C8F7F50F7.png)