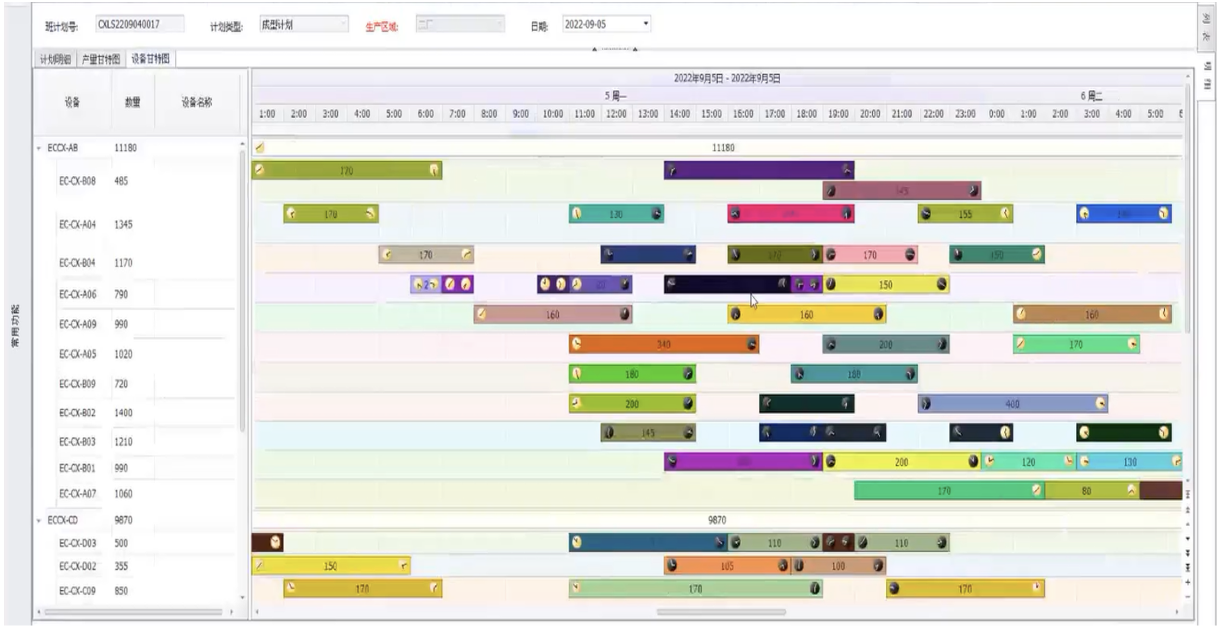

Adapt to the personalized and complex process characteristics of the equipment manufacturing industry, with intelligent algorithms to meet various scheduling scenarios

Optimize bottleneck production capacity and overall resource efficiency in response to the unique nature of production equipment in the equipment manufacturing industry

Balancing production planning and workshop scheduling at different levels of decision-making, multi-level planning scheduling, and direct production planning to the process

Panoramic resource and demand analysis, balanced control of planning and demand, intuitive visualization

Configure heterogeneous system integration universal interface, intelligent backend service automatic execution, solve data exchange barriers

Connecting upper level planning and lower level control, bridging data gaps, from data ownership to data application, transforming data into executable production decisions

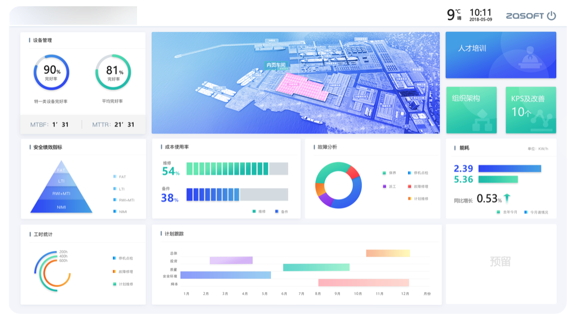

Improve production on site management capabilities through visual management

Realize optimal management and improve material utilization efficiency through production material tracking

Realize real-time performance statistics and strengthen various production related assessments

Strengthening process quality control, automatic association and determination of quality informartion

Strengthen process quality warning, monitor production parameters and process deviations, effectively avoid the spread of quality problems

Strengthen the ability of quality traceability and conduct full-process quality traceability quickly and accurately

Improve quality management methods and further strengthen quality management

Equipment networking and group control to improve equipment efficiency: automatic command issuance, real-time status monitoring, process error prevention control, quality trend warning, intelligent fault diagnosis

Rapid response to equipment abnormalities, reducing production downtime and waiting times

Improve the pertinence of equipment maintenance and reduce maintenance and repair costs

Improve equipment energy management level and reduce production energy consumption

1883D6D19D79454E9B3FA44C8F7F50F7.png)