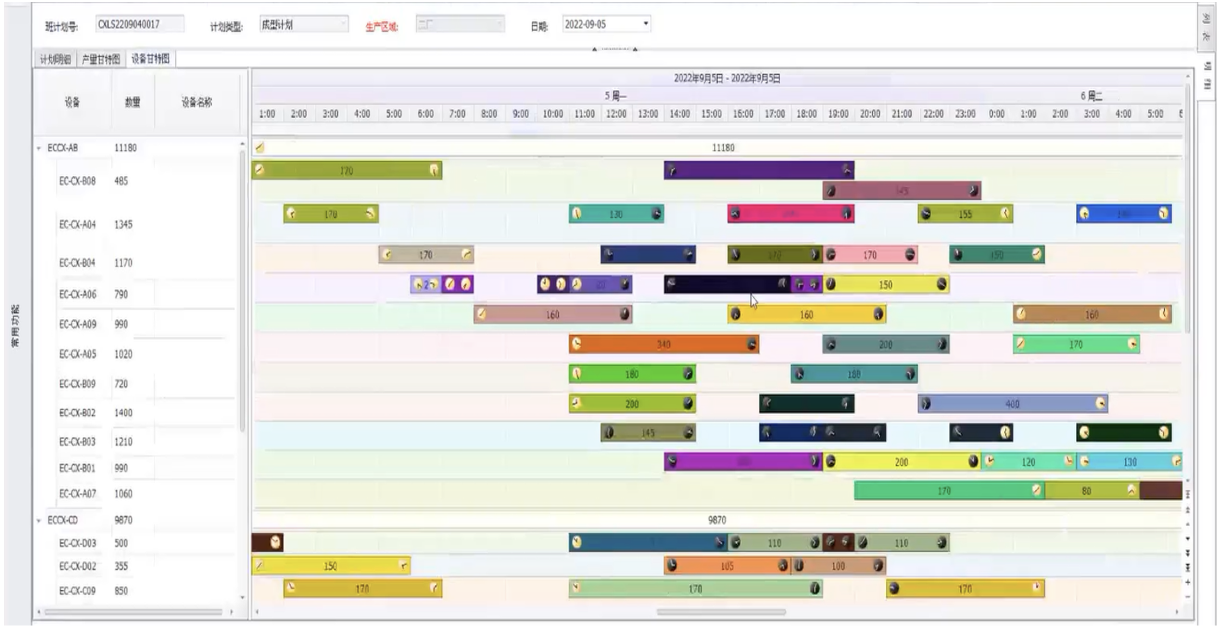

The machining industry has complex processes, diverse products, and high resource dynamics. APS systems can ensure the feasibility and accuracy of plans based on constraint conditions

Targeting the complex process routes and resource sharing characteristics of mechanical processing, multi-level bottleneck identification is carried out, visualized, and resource utilization information is intuitively displayed

Adopting advanced algorithms such as genetic algorithm, linear programming, and constraint theory, with intelligent optimization capabilities, it can quickly process large amounts of order and resource data

Integrate with the warehouse logistics WMS system to achieve production planning that drives material demand and logistics distribution, reducing waiting waste caused by material factors

Integrate with the MES system for production execution, forming a business loop for production planning, execution, and feedback, enabling quick adjustment and optimization of production plans, and responding to production anomalies and emergency order insertion situations

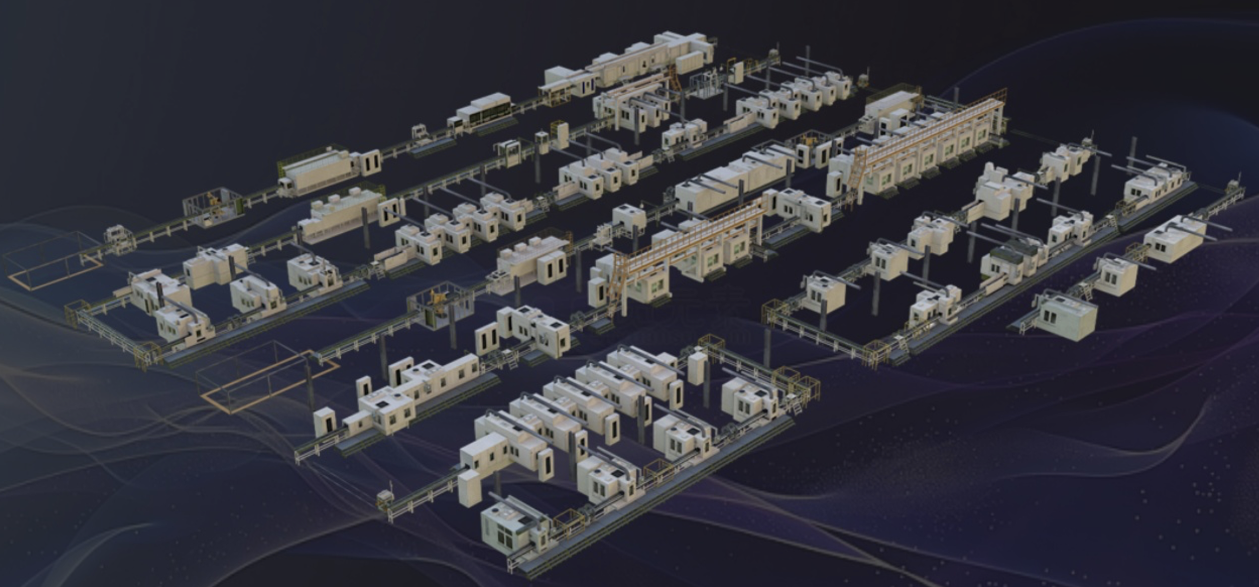

Through real-time, transparent, and intelligent on-site management through MES system, we help enterprises break through the dilemma of "black box production"

Digitization of process documents, integrating drawings, process cards, tool lists, cutting parameters, and real-time retrieval through terminals to avoid "paper file loss" or "parameter misuse"

Dynamic monitoring of work in progress, transparent material flow on site, reducing material accumulation and optimizing inventory turnover

Real time and transparent production progress, multi-level production kanban, allowing management to grasp the on-site production situation in real time

Refine personnel performance by recording each employee's login time, equipment operation, processing tasks, and completion quality as the basis for performance evaluation

Real time response to production anomalies, achieving closed-loop management of monitoring, collection, transmission, warning, disposal, and evaluation of anomalies, and eliminating the occurrence of anomalies from the perspectives of management zeroing and technical zeroing

Mechanical processing production is highly dependent on equipment, and the level of equipment management directly determines production efficiency, quality stability, and cost control capabilities

Comprehensive static management of equipment, achieving full process control of equipment classification management, abnormal monitoring, regular inspection plan, and maintenance work order, reducing unnecessary disassembly and repair, and minimizing spare parts loss

Real time monitoring of equipment dynamics (such as startup rate, load rate, and processing time statistics) can accurately identify "zombie devices" or inefficient links, optimize equipment scheduling, and improve overall production capacity

Based on the Industrial Internet of Things (IoT) platform, it adapts to mainstream communication protocols, operating systems, PLC security, and quickly collects equipment data, clearly grasps the operating status of equipment, and manages work with targeted measures

Build a complete equipment management knowledge system and form a knowledge base

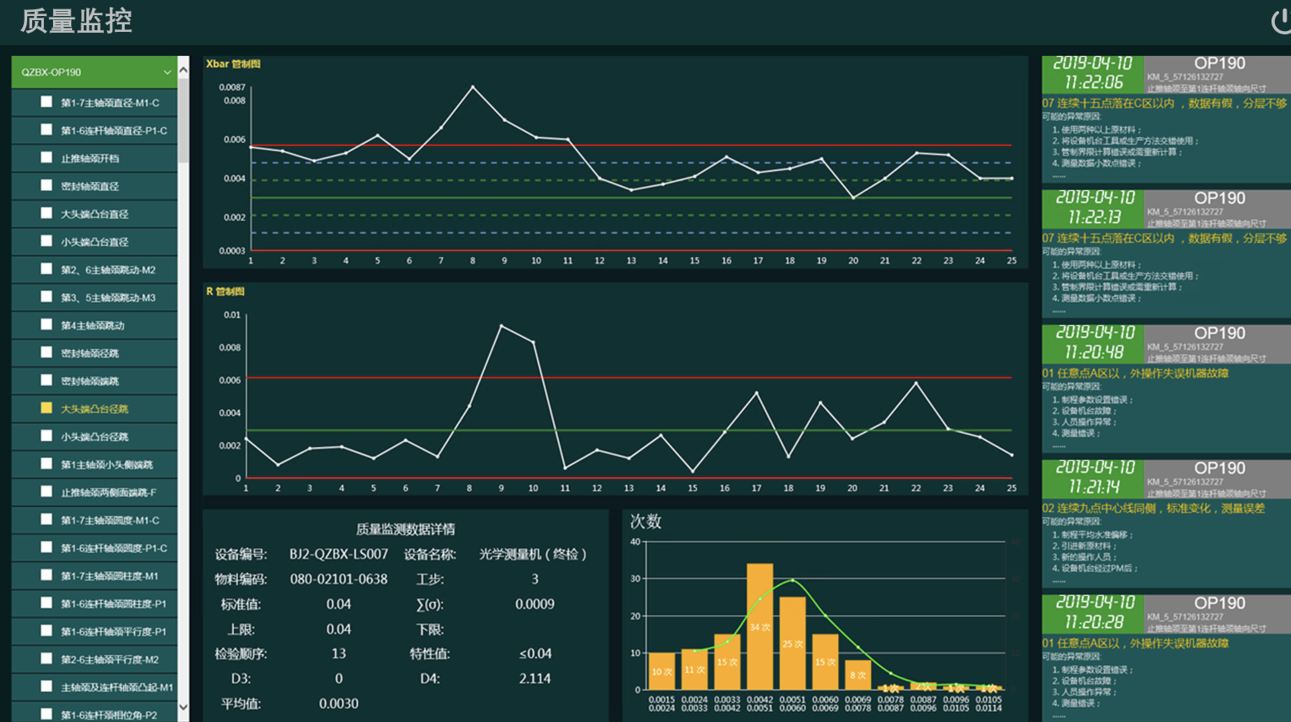

The products in the mechanical processing industry have the characteristics of high precision and strong customization. The QMS system can comprehensively monitor and manage various production processes of mechanical processing enterprises

Enhance the rigor and maintenance efficiency of on-site records, improve the existing method of recording operations, and simplify the complexity of process file management

By integrating the IOT platform for parameter closed-loop control, the actual processing parameters are collected in real-time through the device port and compared with the preset values. If the deviation exceeds the threshold, an automatic alarm is triggered to prevent the production of non-conforming products

Whole life cycle quality management of "raw material quality - production process quality - finished product quality - after-sales quality", building precise quality traceability capability

1883D6D19D79454E9B3FA44C8F7F50F7.png)