Introducing AI algorithms to support rapid mold change (SMED) and dynamic scheduling to reduce waiting waste

Transform manual scheduling experience into a scheduling strategy, based on resource constraints such as equipment, molds, and personnel for intelligent scheduling

Support order disassembly, priority allocation, and flexible response to customer delivery requirements

Resource analysis and production capacity balance and warning, dynamic scheduling of bottleneck processes, improving the feasibility of on-site planning.

On site scheduling optimization, automatic rearrangement of plans and early warning of delivery risks in case of emergency insertion or equipment abnormalities

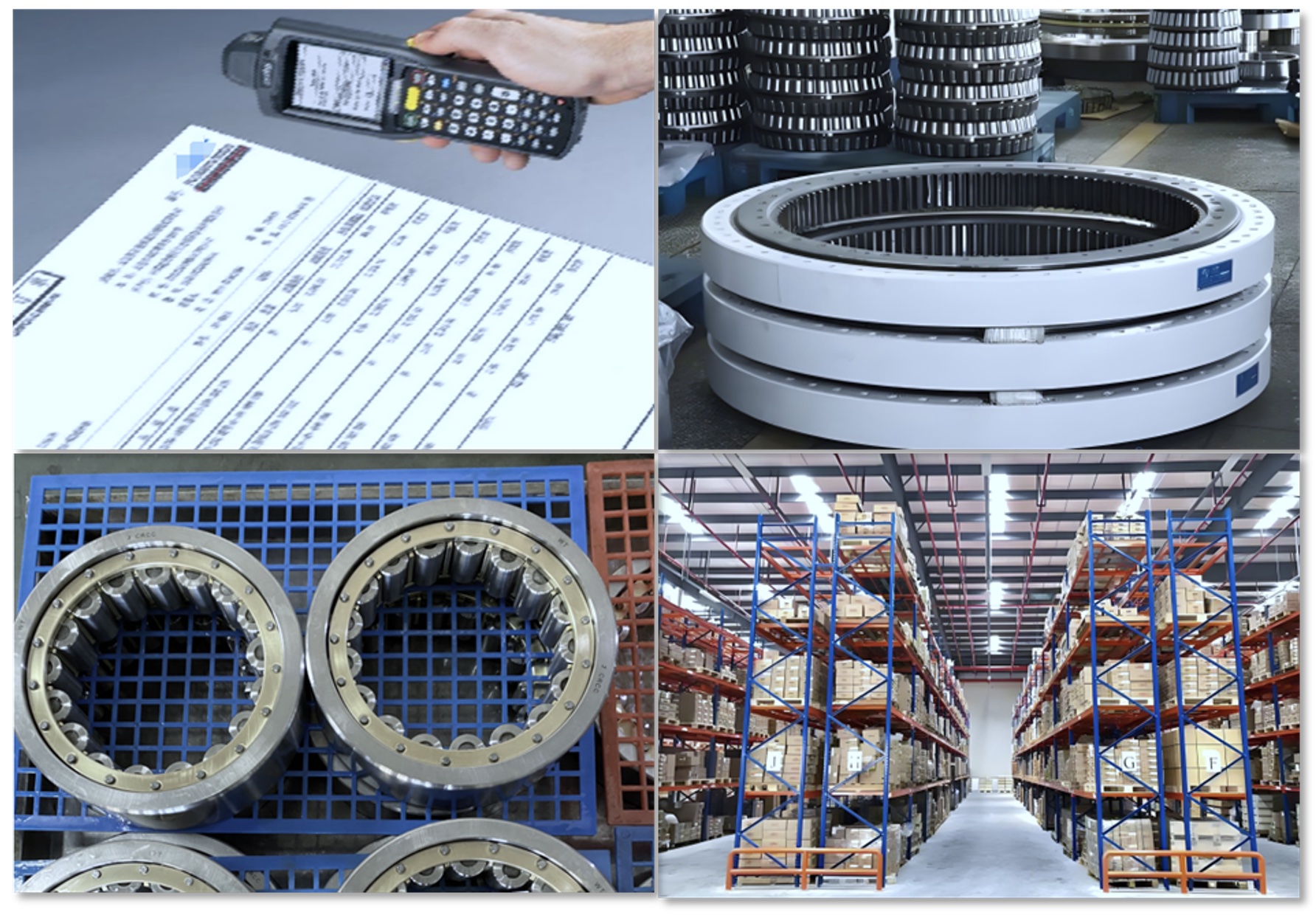

Bind raw material batches, record semi-finished product circulation records, and achieve batch tracking

Optimize multi-level inventory management of materials and standardize warehousing operations

Drive the process flow of raw materials and semi-finished products based on production performance

Automatically verify material matching before assembly process to avoid material shortage

Improve the ability to respond to production changes and achieve real-time collaboration between production and warehousing

Electronic indication of process rules to achieve paperless application of grinding processes

Electronic dispatching of workers to equipment/workstations, integrated with DNC program issuance, to achieve work order collaboration

RFID/barcode scanning verifies materials and process documents to avoid human errors and prevent errors and mistakes

Real time monitoring of the progress, equipment status, and quality indicators of each workstation, displayed through visual dashboards

Timely feedback of production abnormalities and full process tracking

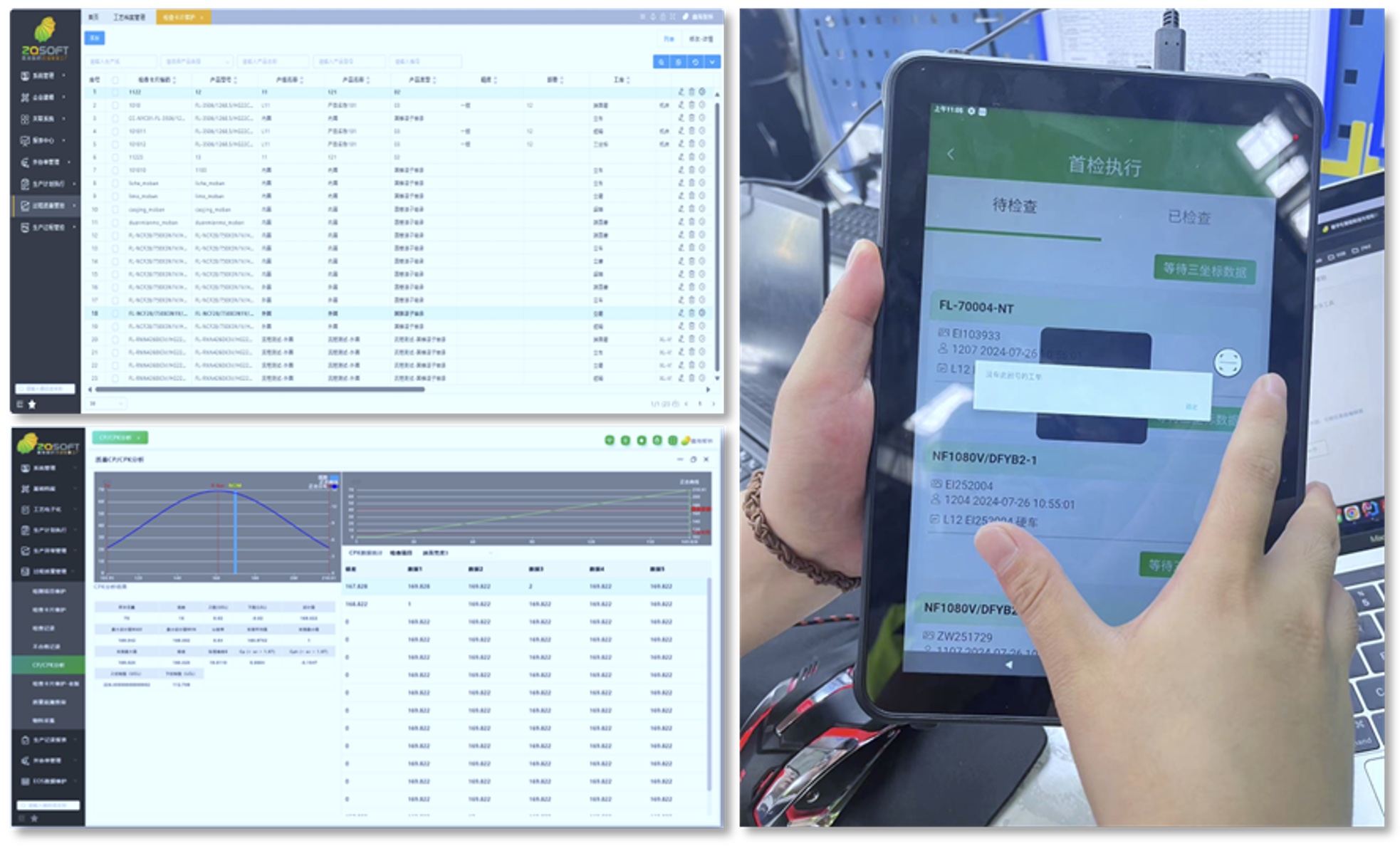

Support custom ring matching models, automatically calculate inner and outer ring matching, efficient and accurate.

Customize inspection strategies, combine grinding and assembly to automatically create inspection tasks, issue, remind and execute them

Integrate with detection equipment to automatically obtain detection data and automatically determine the results

Digital quality inspection application, combined with inspection data to achieve CP/CPK analysis, truly realizes process quality control

The quality inspection results are linked with the conveying device to strictly control the circulation of defective products in the process

Production monitoring based on real-time data from machining and assembly sites

Dynamic analysis of core indicators such as production efficiency, first pass rate, and energy consumption

Multi dimensional visualization data display of machining and assembly production lines

Attribution of costs such as working hours, materials, and waste to support refined improvement

On site multi-dimensional abnormal alarm and tracking

1883D6D19D79454E9B3FA44C8F7F50F7.png)