Develop long-term plans based on overall production capacity planning

Demand and supply linkage, supply chain synergy

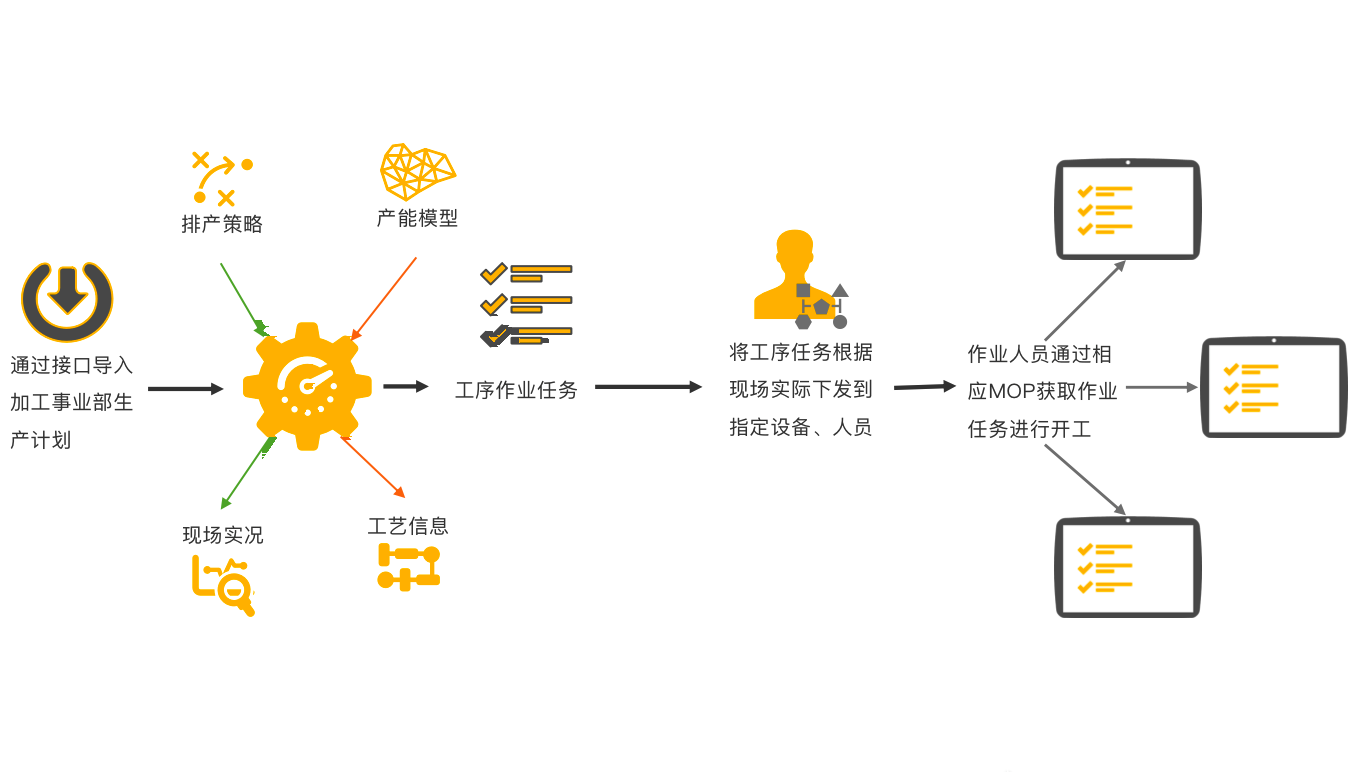

Scheduling job plans at different levels for workshops, processes, and equipment

Based on the actual execution of the plan, achieve global plan tracking and change control

Production task assignment and direct process allocation

Real time display of production information for each workstation or process on the production line

In the case of numerous models, good control should be exercised over the process flow of different models

Levelized production, matching process/production line production rhythm, efficient collaboration

Comprehensive quality management, full process quality data collection and traceability

Visualization and closed-loop control of quality event handling process

Provide accurate data for management decision-making, improve production efficiency and product quality

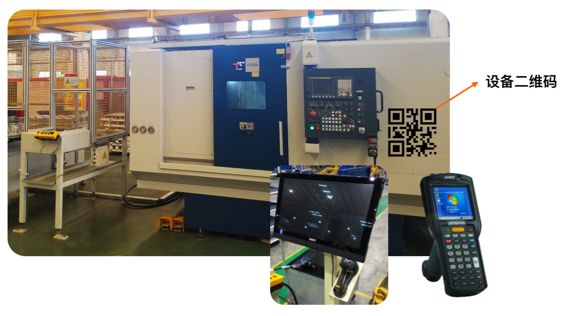

Comprehensive control of maintenance, upkeep, and inspection of equipment assets

Real time acquisition of on-site production equipment data for graphical display

Real time monitoring of the production quantity and online processing status of each device's workpieces

Real time display of equipment failure situation, maintenance personnel can grasp and quickly handle it in a timely manner

Production monitoring and performance analysis

Capacity load assessment and process deviation monitoring

Transparency of production process and manufacturing decision support

Integrated management of production process collaboration and exception handling

1883D6D19D79454E9B3FA44C8F7F50F7.png)