Single machine device networking integration and unified management, automatic data collection, improving detection accuracy

Automatic archiving of experimental data throughout the entire process, automatic generation of reports, and shortening of testing cycles

Connect online data flow, achieve enterprise knowledge accumulation, and improve experimental efficiency

Project based management of detection data, automatic accumulation, tracking, and analysis to form enterprise data assets

Supporting the entire tire manufacturing process: raw material performance, semi-finished product performance, finished tire performance

Standardization and normalization of testing processes in each laboratory;

Ensure traceability of the detection process and message push of key progress nodes during the process;

Realize full lifecycle management of samples;

Various input methods such as automatic instrument collection and manual input for experimental detection results;

Statistical quality control management, control limit and specification limit management trend warning and alarm;

Easy integration of upstream and downstream business systems for tire manufacturing enterprises

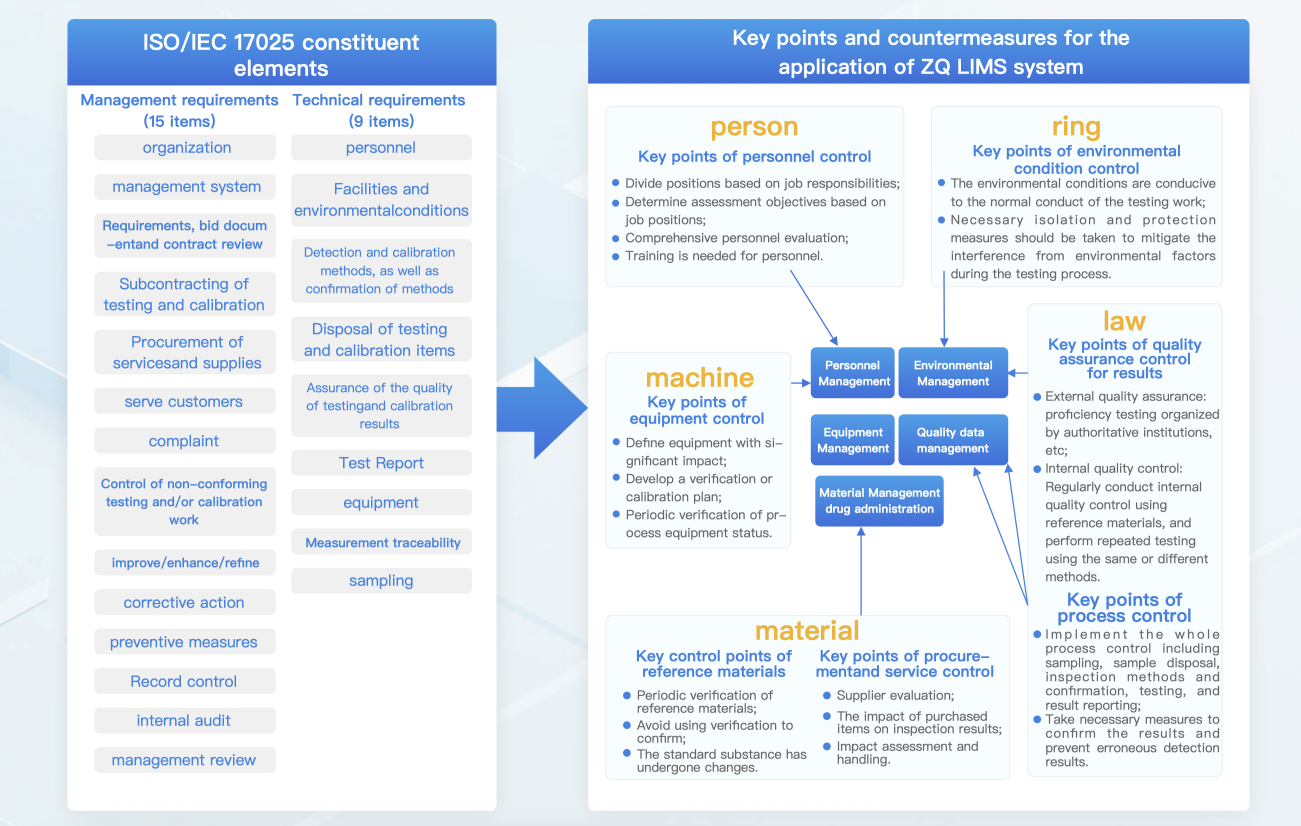

Systematically addressing the core issues of standardization, content standardization, transmission efficiency, and quality control

Transforming and upgrading experimental management from "experience driven" to "data-driven"

Compliant with tire industry standards such as ISO/IEC 17025, FDA 21 CFR Part 11, etc

Capable of audit tracking and electronic signature functions

Compliance auditing can be easily handled

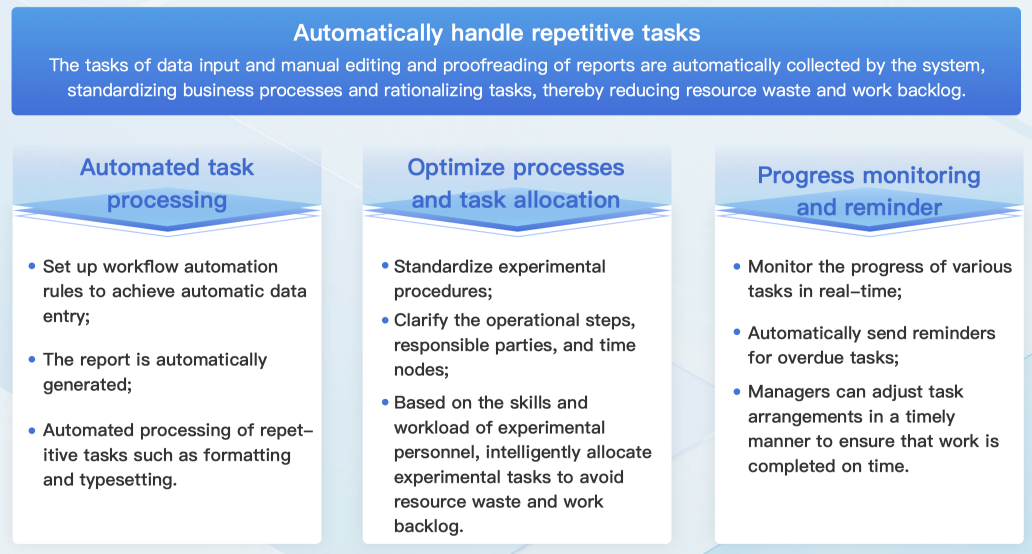

Real time progress tracking: plan issuance, execution, and overdue reminders

Multidimensional resource equipment: project standards, personnel skills, equipment conditions, tooling occupancy

Flexible adjustment: task merging, task postponement, task parallelism

Visual interface: facilitates management personnel to adjust resources, and the system supports visual resource block adjustment.

1883D6D19D79454E9B3FA44C8F7F50F7.png)