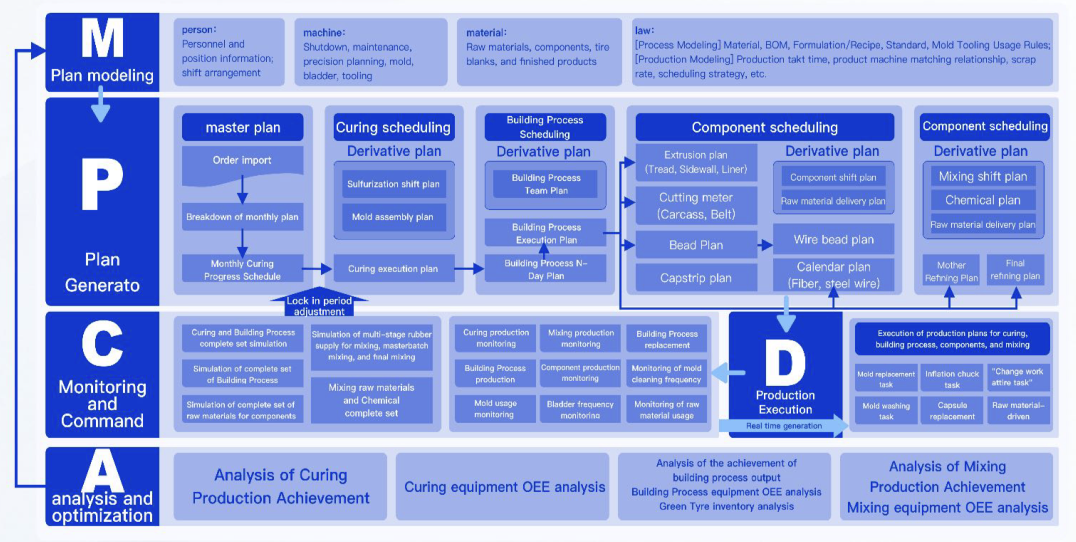

Data Empowerment: Leverage manufacturing big data and intelligent algorithms to build industry-specific scheduling solutions.

Complexity Management: Handle multi-variety, long process, and strong constraints while balancing demand fluctuations, delivery time, cost, and equipment efficiency.

Cross-Plant Coordination: Enable multi-factory scheduling with integrated resource management and dispatching.

Algorithm-Driven Optimization: Apply advanced solvers to achieve globally optimal production planning and execution.

Industry specificity: Tire production involves multiple restrictions such as formula, process, equipment, and molds, presenting a complex feature of "multiple constraints".

Market volatility is high: there are often sudden changes in order demand, coupled with a wide variety of categories and batch differences, resulting in a planning environment full of "uncertainty".

Strong collaboration requirements: There is a high degree of interdependence between production processes, and any delay in any link can trigger a chain reaction, requiring extremely high real-time and flexibility in planning.

Traditional methods are insufficient: the static scheduling mode that relies on manual experience often cannot respond dynamically and is difficult to adapt to the "multi constraint, high fluctuation, and strong collaboration" scheduling needs of the tire industry.

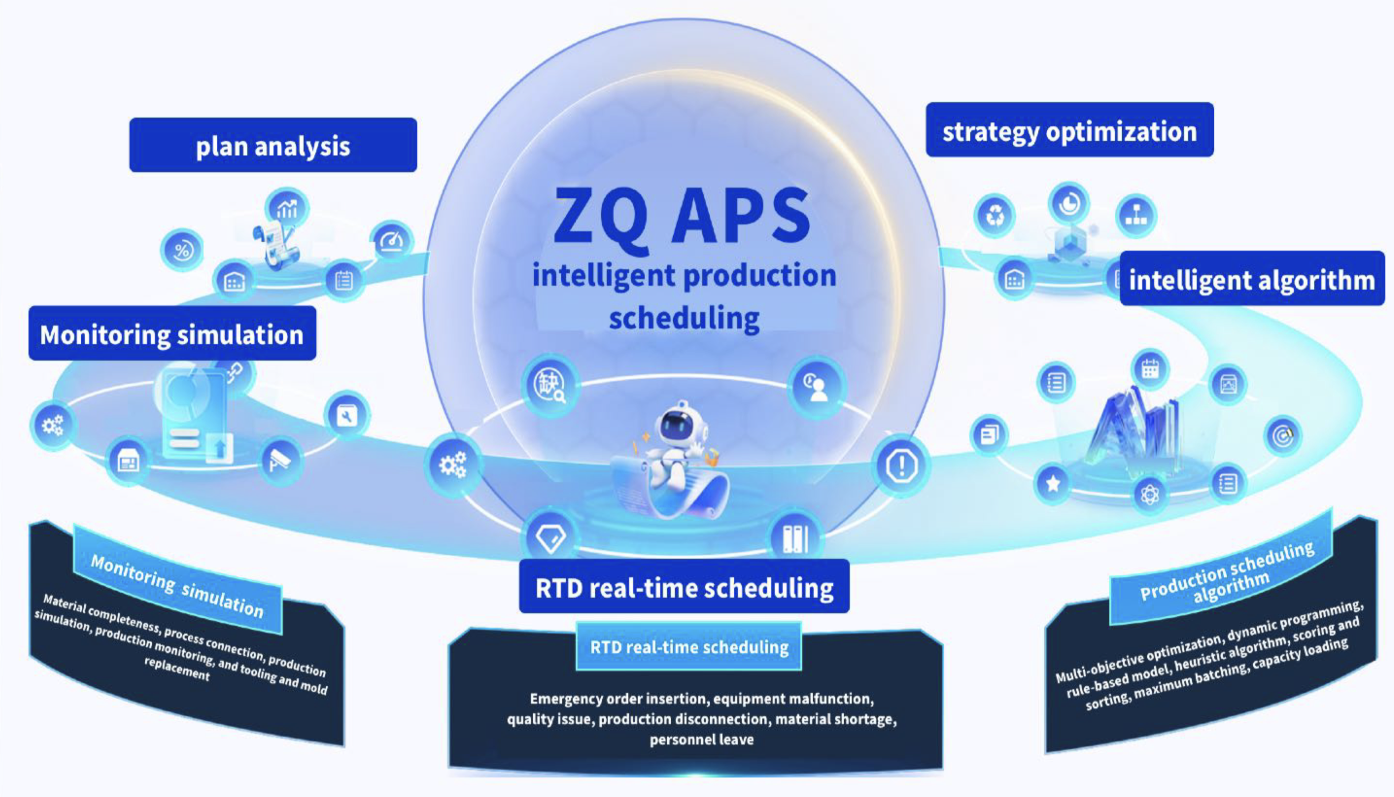

Mode upgrade: ZQ APS deeply integrates with lean concepts to achieve the transformation of production management from "experience driven" to "data-driven".

Real time response: relying on real-time simulation and RTD scheduling functions, it can quickly respond to uncertain scenarios such as equipment failures, order changes, and material shortages.

Breaking through limitations: Overcoming the shortcomings of traditional lean methods that rely on manual labor and are difficult to dynamically adjust, making production scheduling more flexible and intelligent.

Comprehensive value: Providing enterprises with accurate information flow, efficient resource collaboration, and fast problem response capabilities, helping to improve production efficiency.

Intelligent strategy driven: Adopting intelligent scheduling strategies and advanced algorithms to build efficient business models.

Full process visual control: Through production simulation, real-time monitoring of the progress of material and tooling connection ensures smooth production processes.

Real time flexible scheduling: With the help of RTD real-time scheduling, quickly handle production and quality anomalies, and achieve dynamic optimization of plans.

Maximizing Value: With the goal of minimizing costs, optimizing inventory, maximizing efficiency, and minimizing delivery, we aim to comprehensively enhance the competitiveness of the enterprise.

1883D6D19D79454E9B3FA44C8F7F50F7.png)