Understand the correlation between material → performance → design → process → application

Optimize tire performance (rolling resistance, wear resistance, grip)

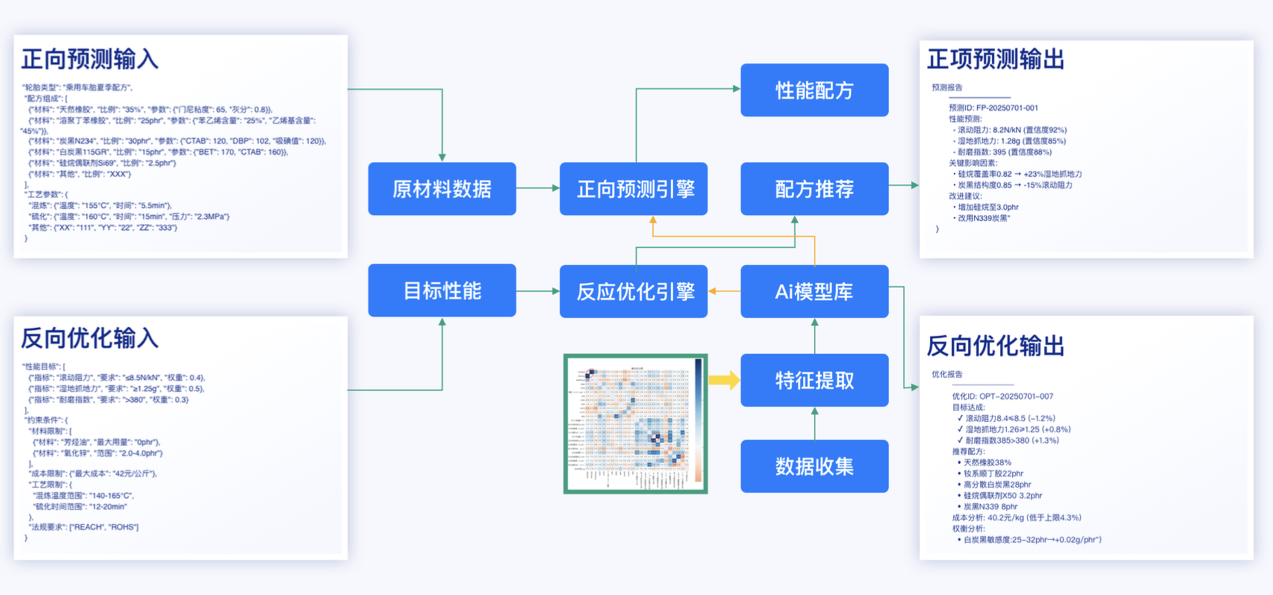

Through the dual engine of forward prediction and backward optimization, an intelligent closed-loop system for "performance-formulation" is achieved

Through intelligent technology, complex production plans are transformed into a computable and optimizable decision-making process.

Fully perceive and integrate multi-source knowledge (such as production paths, equipment capabilities, rule constraints, order delivery dates, etc.) in the production system, and build a precise description rule base

Utilizing algorithm optimization, multiple objectives such as "minimizing order delays" and "maximizing capacity utilization" are transformed into solvable mathematical models, and intelligent calculation yields an optimal or satisfactory production scheduling plan under various constraints.

It transcends traditional static scheduling, responds quickly to production changes and adjusts plans promptly, while continuously self-optimizing through continuous learning from historical data, thus forming an intelligent decision-making closed loop that becomes smarter with use, ultimately achieving the core goals of ensuring delivery, improving efficiency, and reducing costs.

Build an intelligent closed loop for quality management through a three-in-one AI solution that integrates intelligent quality inspection, defect prediction, and root cause analysis

Defect prediction: Early warning of risks, shifting from reactive rework to proactive prevention, achieving improved product yield;

Root cause analysis: Minute-level identification of the source of the problem, shortening the quality analysis cycle, and preventing the recurrence of similar issues.

With the core principle of "data-driven decision-making and AI-enabled closed loop", we aim to drive enterprises to transition from "post-error correction" to "real-time prevention and control". This will assist manufacturing enterprises in transforming quality control from a "cost center" into a "competitiveness engine", accelerating their journey towards a new era of zero-defect intelligent manufacturing

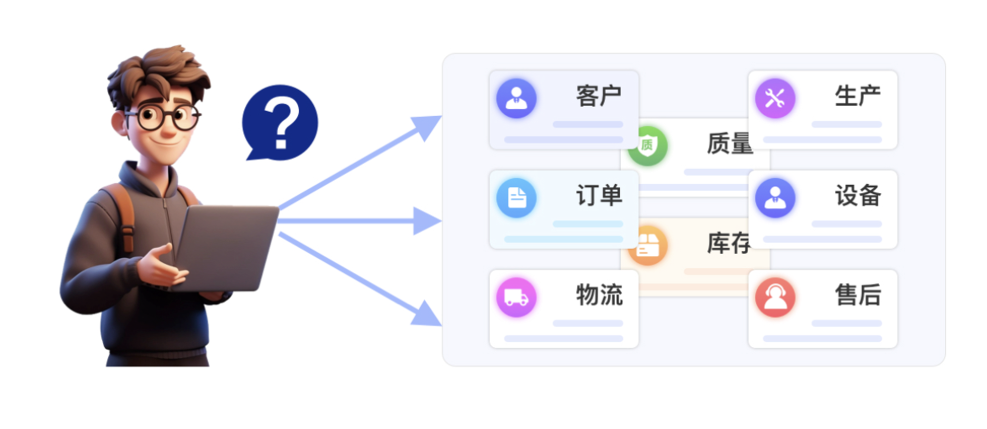

Through deep understanding and knowledge integration, we transform users' natural language queries into precise information retrieval and generation tasks.

Utilize Natural Language Processing (NLP) technology to analyze user intent and precisely retrieve relevant information from the enterprise's vast data pipeline.

Utilizing the powerful comprehension and generation capabilities of Large Language Models (LLMs), digest, integrate, and rewrite the retrieved information to generate direct, accurate, and contextually coherent answers

Replacing "time-consuming, low-value" repetitive tasks with AI frees employees from the cycle of "checking data, making reports, and waiting for feedback", allowing them to focus on core business. Enabling managers to grasp enterprise dynamics anytime, anywhere, this is the efficiency revolution brought by AI to enterprises

It transcends traditional keyword matching search, possesses multi-round dialogue and contextual memory capabilities, and continuously optimizes answers during interaction, thus forming a conversational information acquisition portal that truly understands user needs.

Discover hidden patterns and establish causal connections, transforming vast and chaotic data into driving insights.

Automatically clean, integrate, and process data from multiple dimensions and sources to prepare for in-depth mining.

Utilizing machine learning, statistical methods, and deep learning models, we transcend traditional statistics to conduct in-depth diagnostic, predictive, and prescriptive analyses, thereby uncovering complex associations, trends, and anomalies that are difficult for the human brain to discern.

Real-time monitoring: At the group level, it can monitor the overall operational health of the company; at the workshop level, it can monitor the status of production line equipment, with data updated in real-time and automatic alerts for abnormal situations;

Horizontal comparison: Compare the operational status of companies, departments, and production lines, allowing management models to learn from each other and enabling underperforming departments to identify areas for improvement

Problem identification: Through "drill-down analysis", we traced the "decline in sales" to "delayed regional orders", and then to "shortages of raw materials", ultimately identifying the root cause with one click.

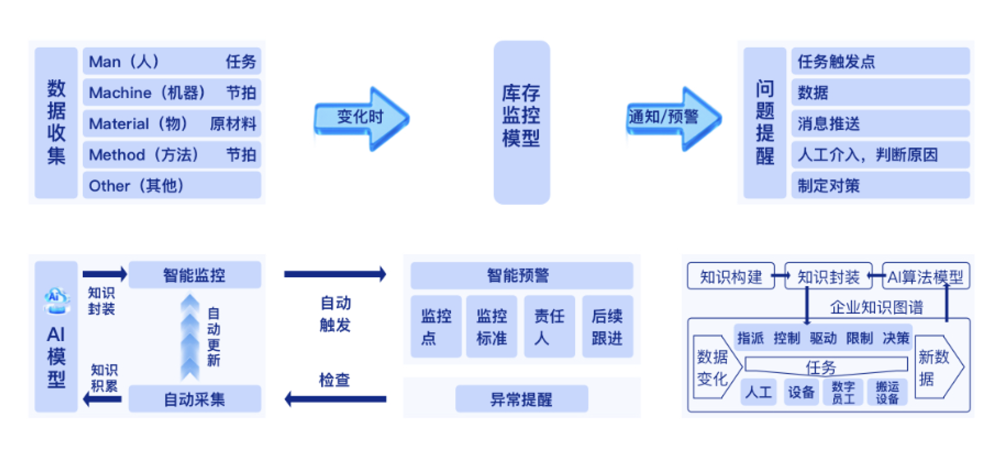

Through real-time monitoring and predictive modeling, we can transform passive response to risks into active prevention and control of risks.

Establish a round-the-clock data monitoring system that covers key indicators, continuously collecting and processing real-time data streams.

Utilizing time series analysis, anomaly detection algorithms, and predictive models, based on historical patterns and current trends, intelligently identify minor deviations, predict future trends, and issue early warnings when risk parameters exceed dynamic thresholds.

Replace "empirical judgment" with "data model" to provide a basis for decision-making, bring "hidden problems" to the surface, and shift from "solving problems" to "preventing problems"

It transcends the traditional threshold alarm based on fixed rules, possesses early warning and traceability capabilities, can distinguish between different levels of anomalies, infer the root cause, and provide preliminary disposal suggestions. Thus, it upgrades a simple alarm system into a forward-looking risk prevention and control system, achieving a shift from "post-event remediation" to "pre-event prevention" and "in-process intervention".

Through multi-source information fusion and real-time situation assessment, decisions in complex scenarios are transformed into automated and intelligent action commands.

Utilizing data from Internet of Things (IoT) sensors, video surveillance, business systems, and other sources, a real-time synchronized "digital mirror" of the physical world is constructed, comprehensively sensing the status of elements such as personnel, equipment, materials, processes, and the environment.

Based on preset rules, optimization algorithms, and reinforcement learning strategies, it can quickly calculate and generate optimal action plans in a rapidly changing environment.

Shifting from traditional single-point operations or manual scheduling to collaborative linkage and dynamic optimization enables managers to move from "making decisions based on intuition" to "being data-driven", making risks visible and opportunities graspable.

1883D6D19D79454E9B3FA44C8F7F50F7.png)