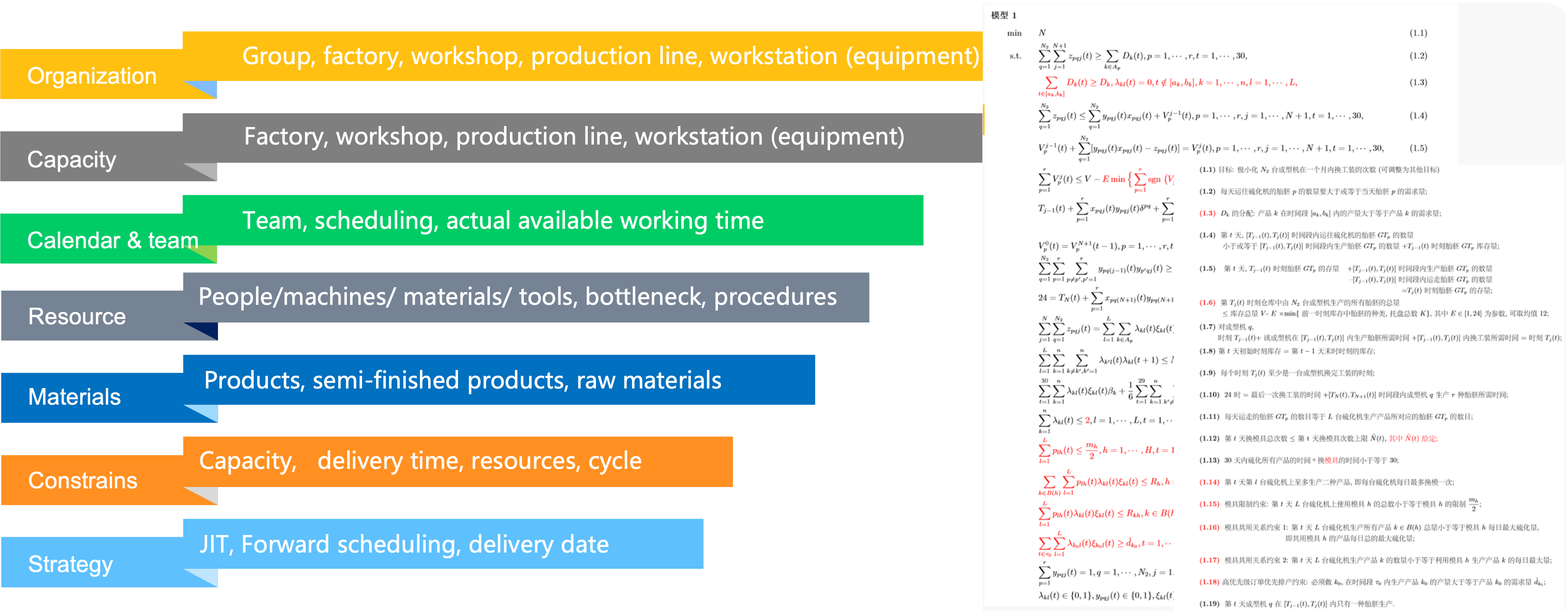

Based on a self-developed production logic model, it can handle the production of different types of orders.

Algorithm engine, precise constraints, and human experience enable executable and operable production scheduling.

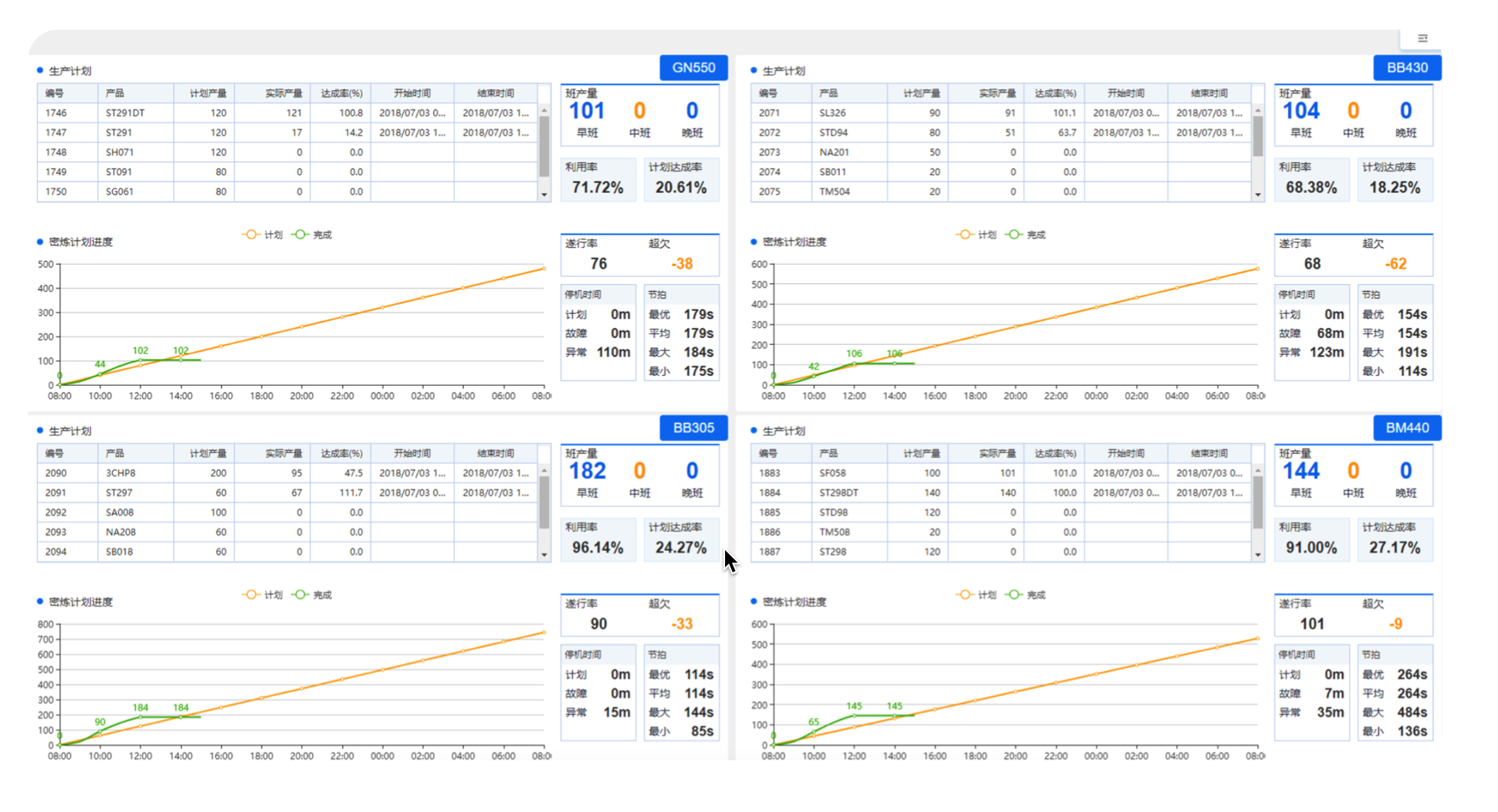

Plan on-site linkage technology ensures accurate issuance and execution of plans.

Through various scheduling strategies in the ZQ-APS system, achieve a balance between production capacity, efficiency, and load.

Plan monitoring and completion reporting management make plan execution highly transparent.

Collaborate with MBOM management to calculate differentiation and facilitate personnel identification of differences.

The material requirement list is automatically generated, making the production materials clearly visible.

The system automatically calculates material requirement planning to provide efficient support for supply chain collaboration.

Intelligent optimization of long-term or short-term plans to improve plan feasibility.

Simulate parallel resources to plan for limited resources.

Simultaneously check constraints such as resources, capabilities, requirements, and processes to optimize scheduling.

Accumulate big data, continuously enrich the knowledge base in practice, and optimize self-learning during operation.

Develop a flexible production model based on the principles of lean production.

According to the requirements of the homework task, form an optimal structure on your own.

Quickly respond to anomalies and order changes, with worry free planning and distribution throughout the entire process.

1883D6D19D79454E9B3FA44C8F7F50F7.png)