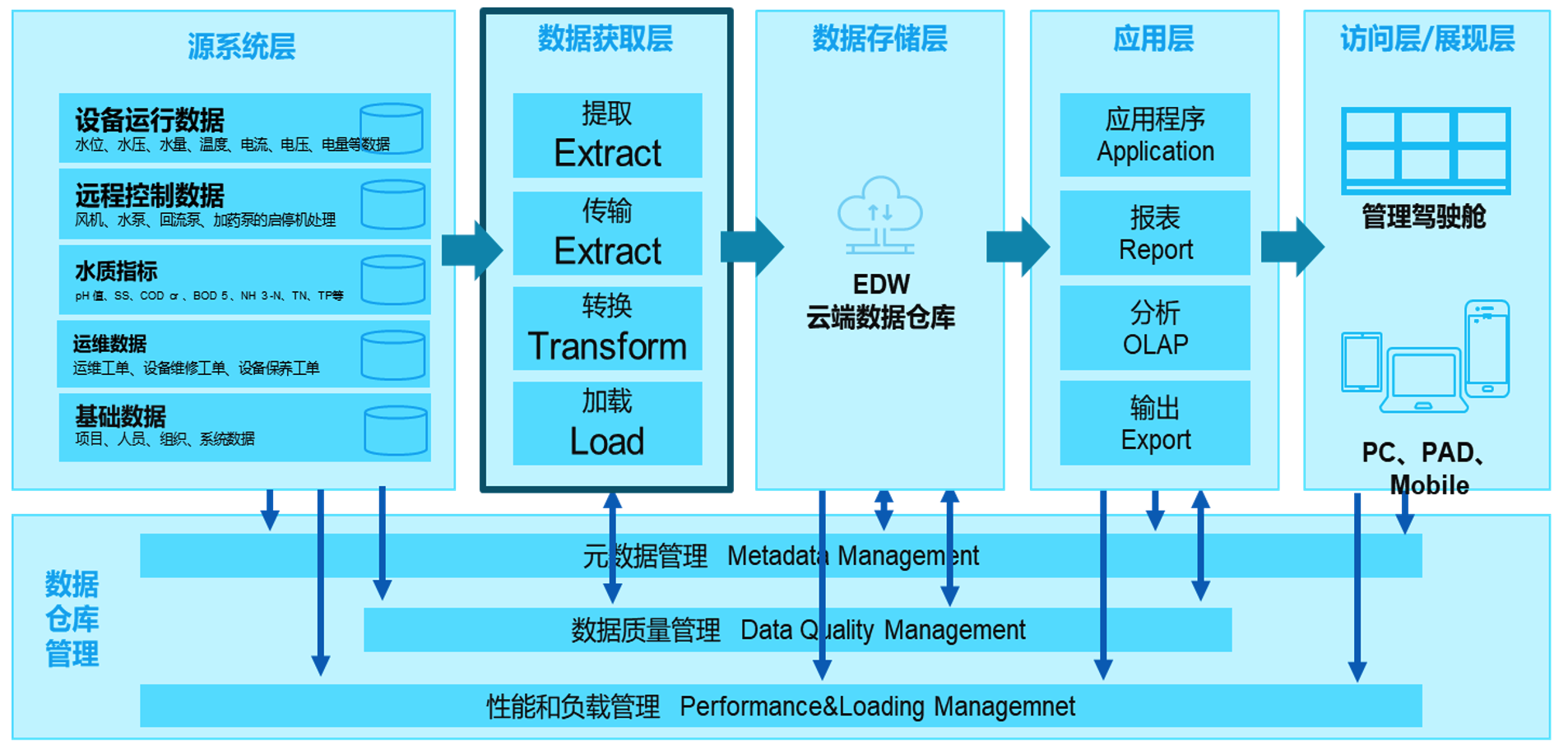

Extraction:

Reading data from various raw business systems is a prerequisite for all work

Conversion:

Convert the extracted data according to pre designed rules to unify the originally heterogeneous data format

Loading:

Import the converted data into the data warehouse in increments or in full according to the plan

Cross application data fusion computing, completing data extraction, transformation, and loading

Distributed deployment, supporting multiple databases, integrating OPC UA to connect industrial equipment

Integrate powerful Exceptionless distributed logs to troubleshoot exceptions

Help enterprises quickly build data pipelines between heterogeneous data sources

By configuring, the connection of various objects can be completed to meet personalized needs

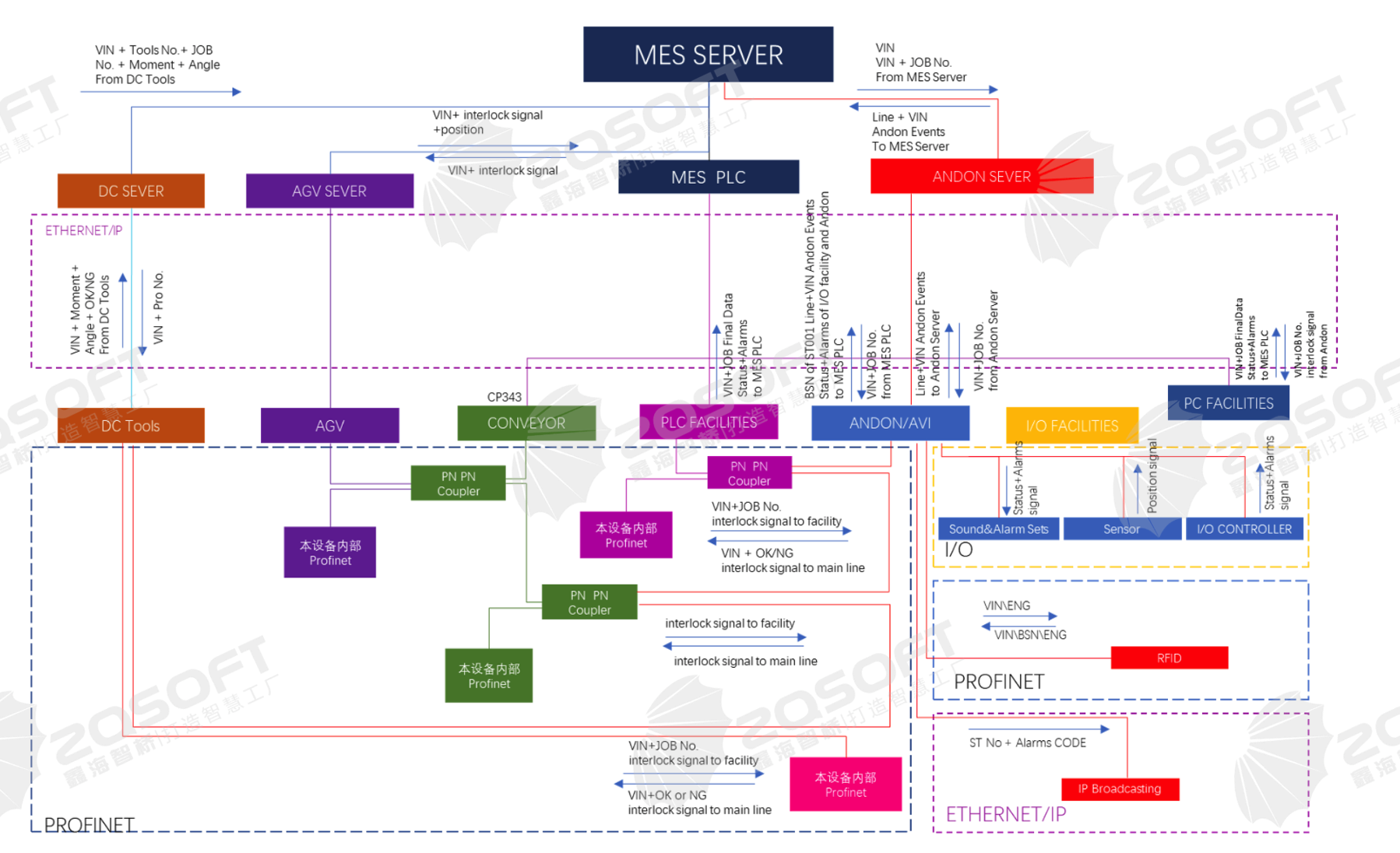

Fully supports multiple standard protocols, CNC systems, PLCs, etc

Comprehensive response to machining equipment, assembly equipment, testing equipment, laboratory equipment, energy equipment, etc

Safely and quickly collect device data, solve data loss caused by storage and PLC response time difference

Edge computing, improving the efficiency of system device and device device interaction

Support future oriented data application expansion

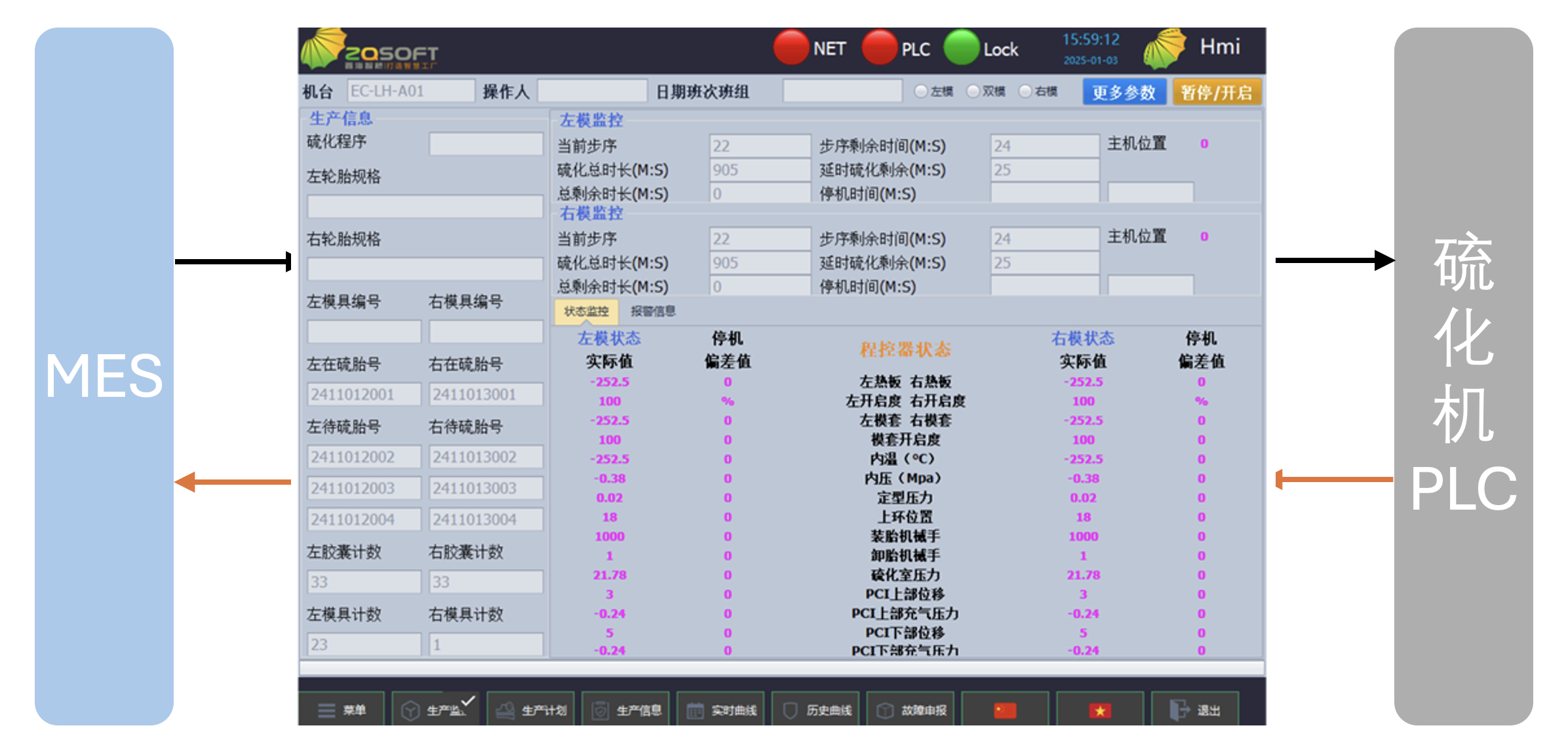

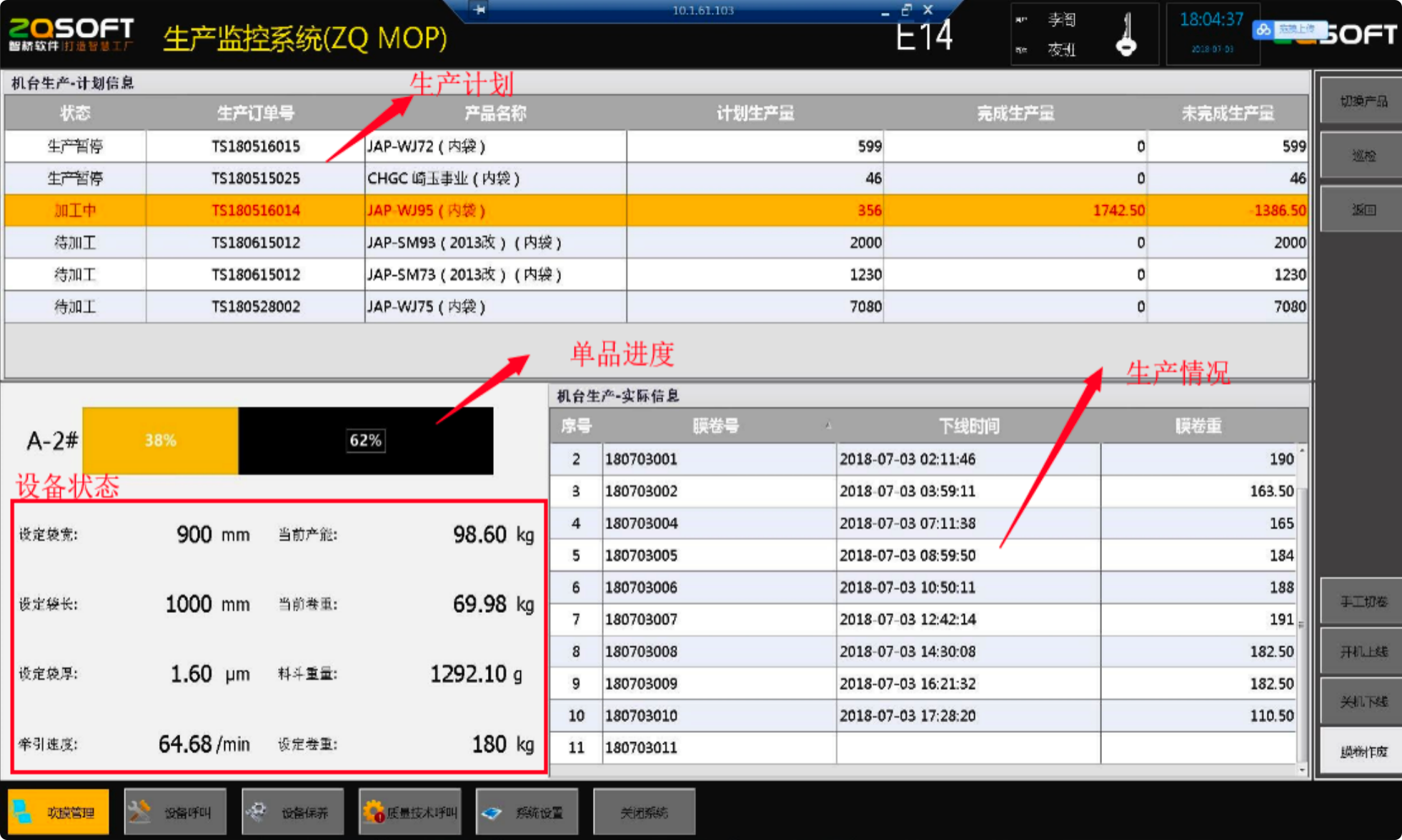

Open up system barriers: achieve direct connection between MES and equipment, and build an efficient and seamless data exchange system.

Safe and reliable: Accurately distribute MES data, collect real-time production information, and securely store historical data to ensure data integrity and reliability.

Concise and intuitive: user-friendly interface, easy operation, real-time monitoring and precise control of vulcanization process, improving production management efficiency.

Efficient and flexible: The process parameters are flexible, adjustable, storable, and traceable, meeting diverse production needs and helping enterprises upgrade their intelligent manufacturing.

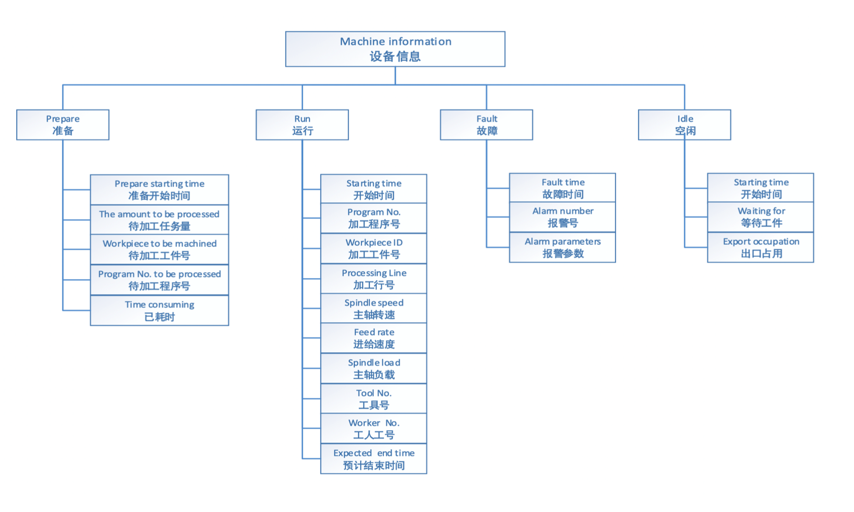

It can be seamlessly integrated with DNC, MES, APS, ERP and other systems

More accurate plans and more scientific measures

Can customize personalized functions and interfaces according to users' actual needs

Strong compatibility with CNC equipment, industrial control equipment, automation equipment and other systems

Compatible with 99% of CNC systems,PLC,suitable for over 1000 types of industrial equipment

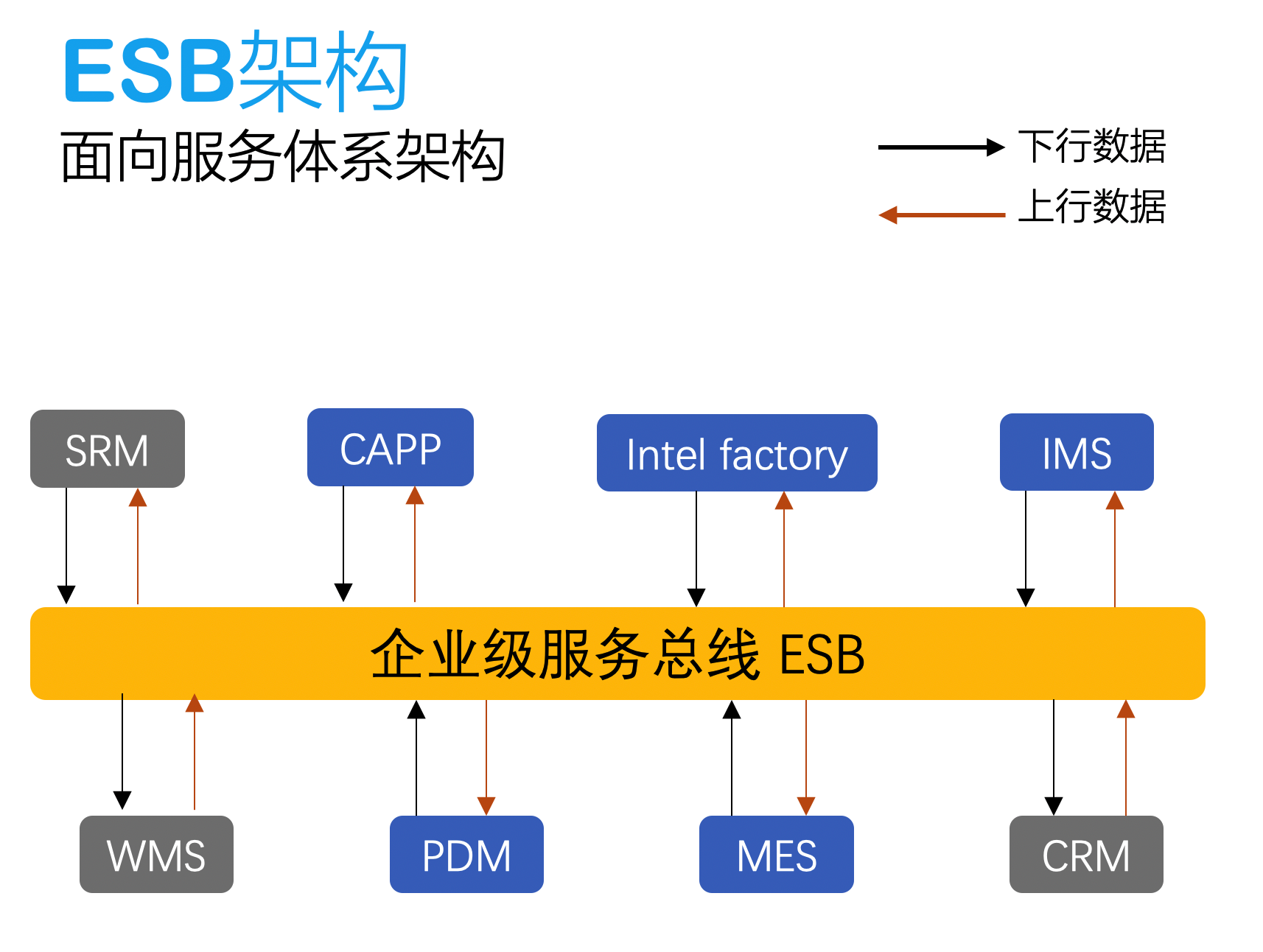

Breaking down system barriers and building industrial big data

Integrating and centralizing services through enterprise service bus

Flexibly connect with standard interfaces to achieve true on-demand adaptability

1883D6D19D79454E9B3FA44C8F7F50F7.png)