Quality issues in tire manufacturing are often hidden and cumulative. Defects generated in early processes may go unnoticed and become amplified in later stages, leading to rework or scrap.

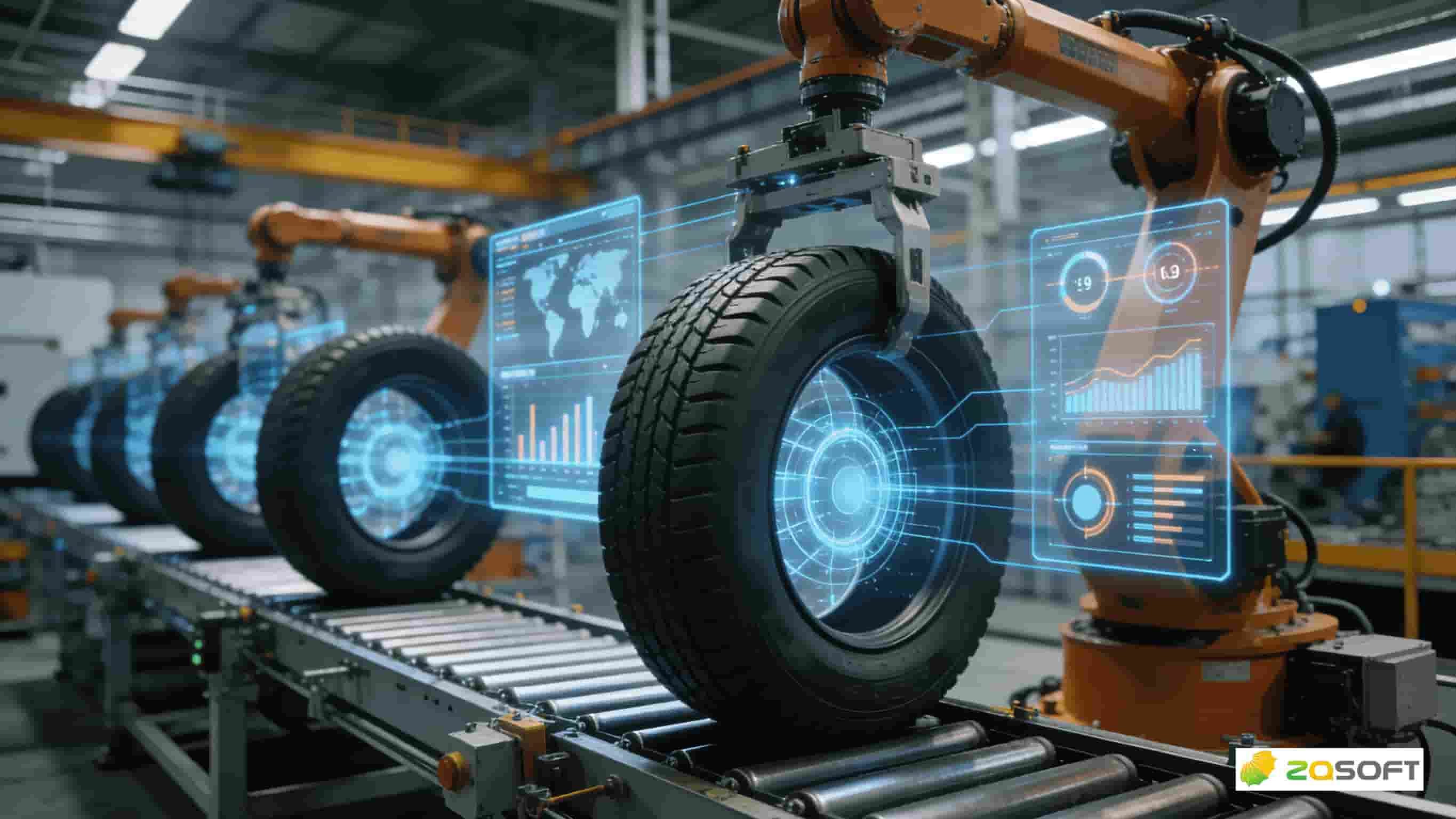

Therefore, effective quality management should focus not only on traceability after problems occur, but on prevention during production. By integrating QMS with MES, critical quality parameters can be monitored and collected in real time.

When abnormal trends are detected, the system can trigger alerts or intervention mechanisms to prevent further impact. At the same time, a complete traceability system provides valuable data for analysis and continuous improvement.

In its quality management projects, ZQSOFT emphasizes a closed-loop approach combining prevention, process control, and traceability—helping tire manufacturers reduce risks, improve consistency, and strengthen brand reputation.

1883D6D19D79454E9B3FA44C8F7F50F7.png)