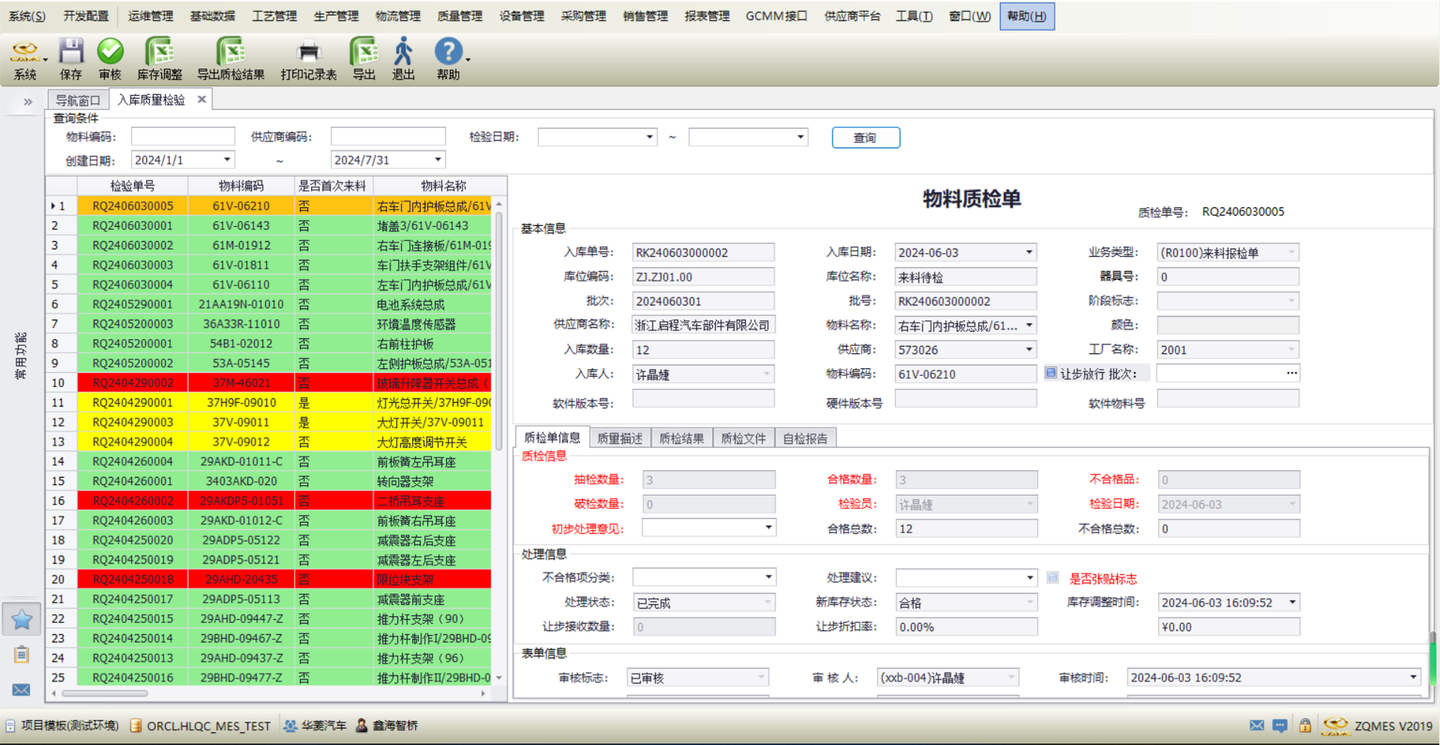

In the production chain of manufacturing, the quality of raw materials is the cornerstone that determines the final product quality, and incoming inspection is the core means of controlling this critical link.

In recent years, the tire industry has accelerated the upgrading of digitalization and intelligence. How to achieve efficient collaborative production, quality traceability, and real-time equipment monitoring has become the key to the transformation of manufacturing enterprises.

MES (Manufacturing Execution System) needs to obtain relevant process, quality, and output data during the production process in order to achieve the goals of digitalization, transparency, and real-time production.

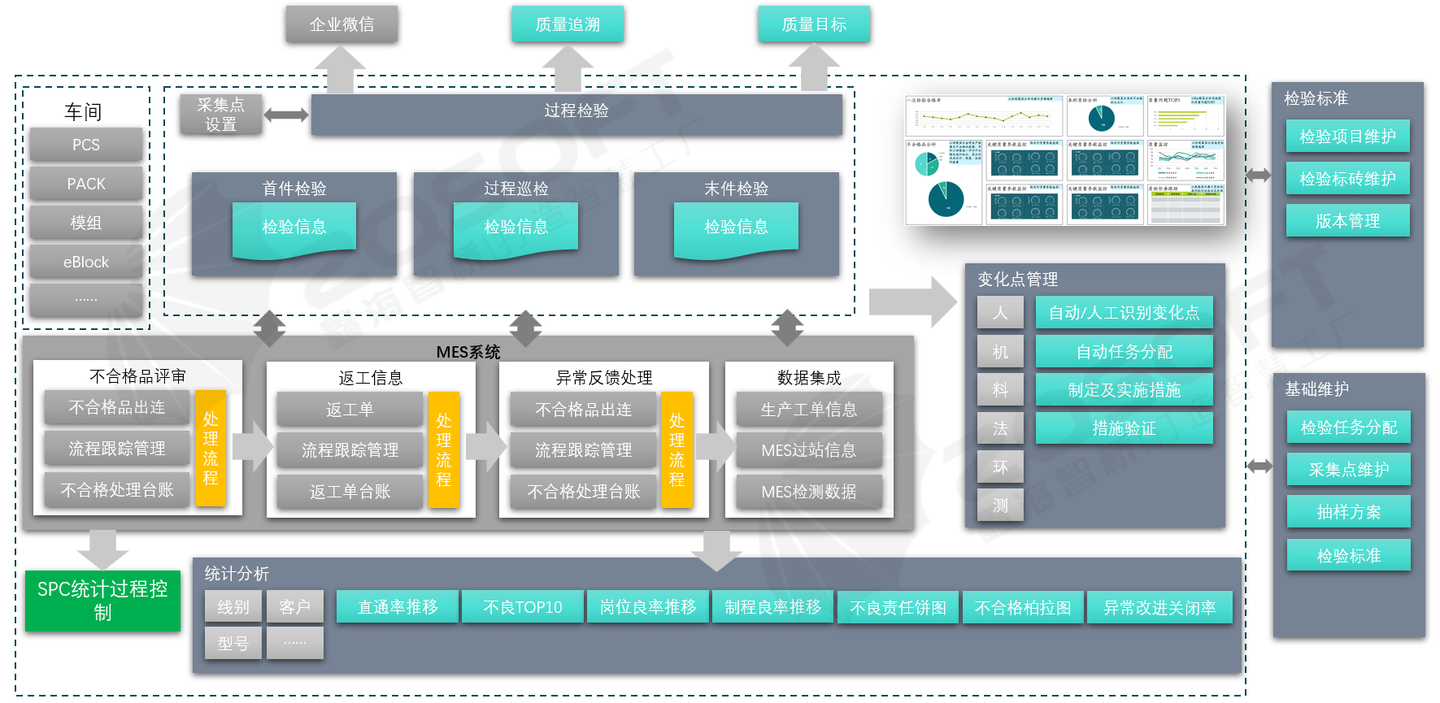

In the current booming development of the new energy industry, the battery assembly industry, as a key link, continues to see an increase in market demand. However, battery products have extremely high requirements for safety, stability, and consistency.

The equipment data acquisition technology of MES (Manufacturing Execution System) is the core link to achieve digitalization and transparency of the production process. Its goal is to obtain real-time and accurate information on equipment operation status, process parameters, production data, etc., providing data support for production scheduling, quality control, equipment maintenance, etc.

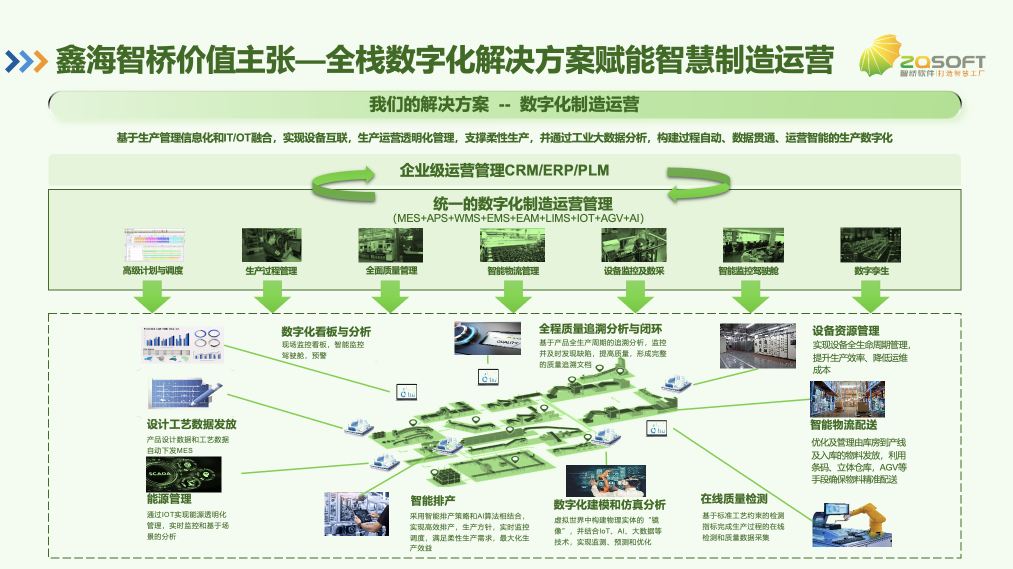

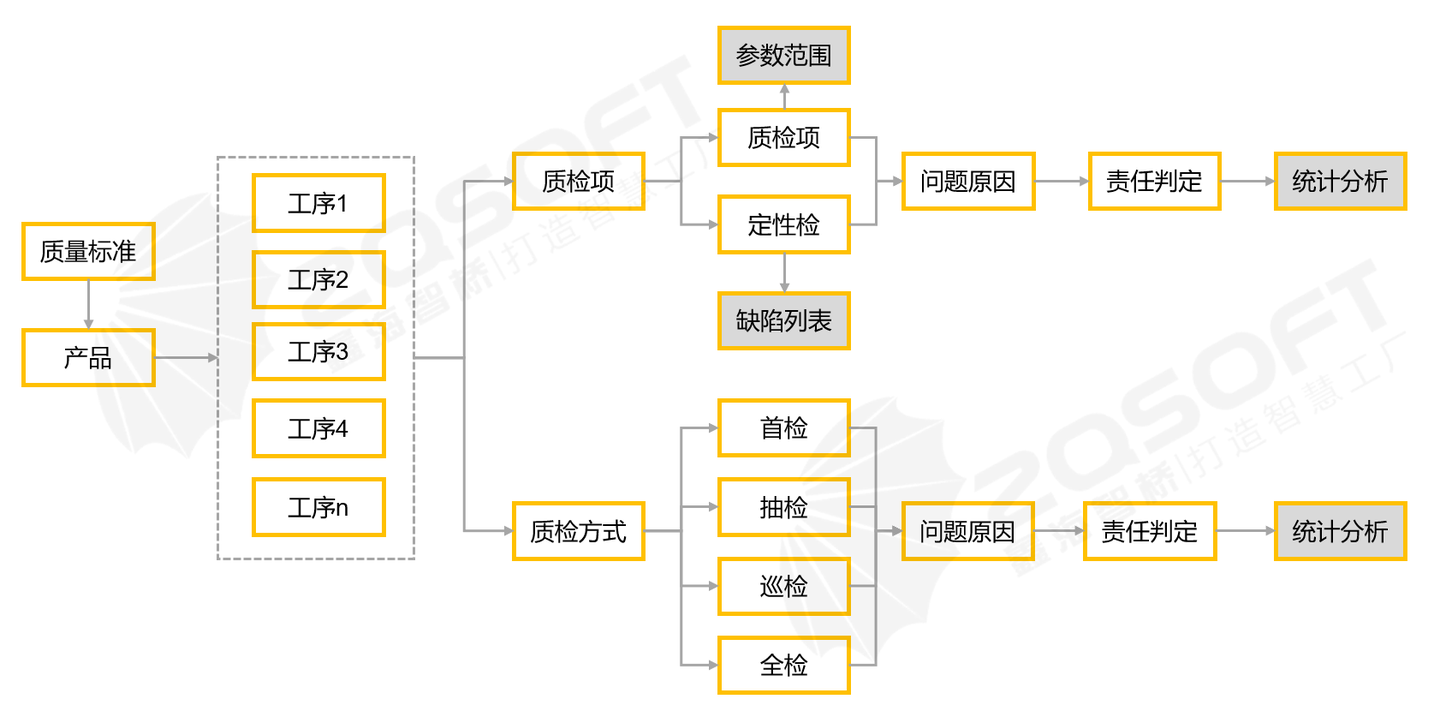

In modern manufacturing, the Manufacturing Execution System (MES) serves as a crucial bridge connecting the enterprise planning layer with the production control layer, playing a pivotal role in achieving process quality control.

With the increase in global car ownership and the rapid development of new energy vehicles, the demand for tires in the market will continue to grow. Under the dual pressure of environmental protection requirements and funding, small and medium-sized tire enterprises will accelerate their clearance, outdated production capacity will gradually be eliminated, industry concentration will further increase, and top enterprises will occupy a larger market share.

Currently, the traditional tire manufacturing industry is facing the dilemma of high production and circulation costs, low efficiency, and serious resource waste. Faced with fierce competition caused by product homogenization, it is necessary to find better solutions from the perspective of efficiency improvement. The rapid changes in market demand require enterprises to have faster and more agile response capabilities.

The construction of smart factories has become an important means for tire companies to enhance their competitiveness. Especially Chinese tire companies have increased their investment in the field of intelligent manufacturing, building new intelligent factories to improve production efficiency and product quality, adapt to changes in market demand, and enhance market competitiveness. Automated logistics is an important component of smart factory construction.

1883D6D19D79454E9B3FA44C8F7F50F7.png)