Paperless office improves information transmission efficiency

Full process and standardized quality control make quality management simpler

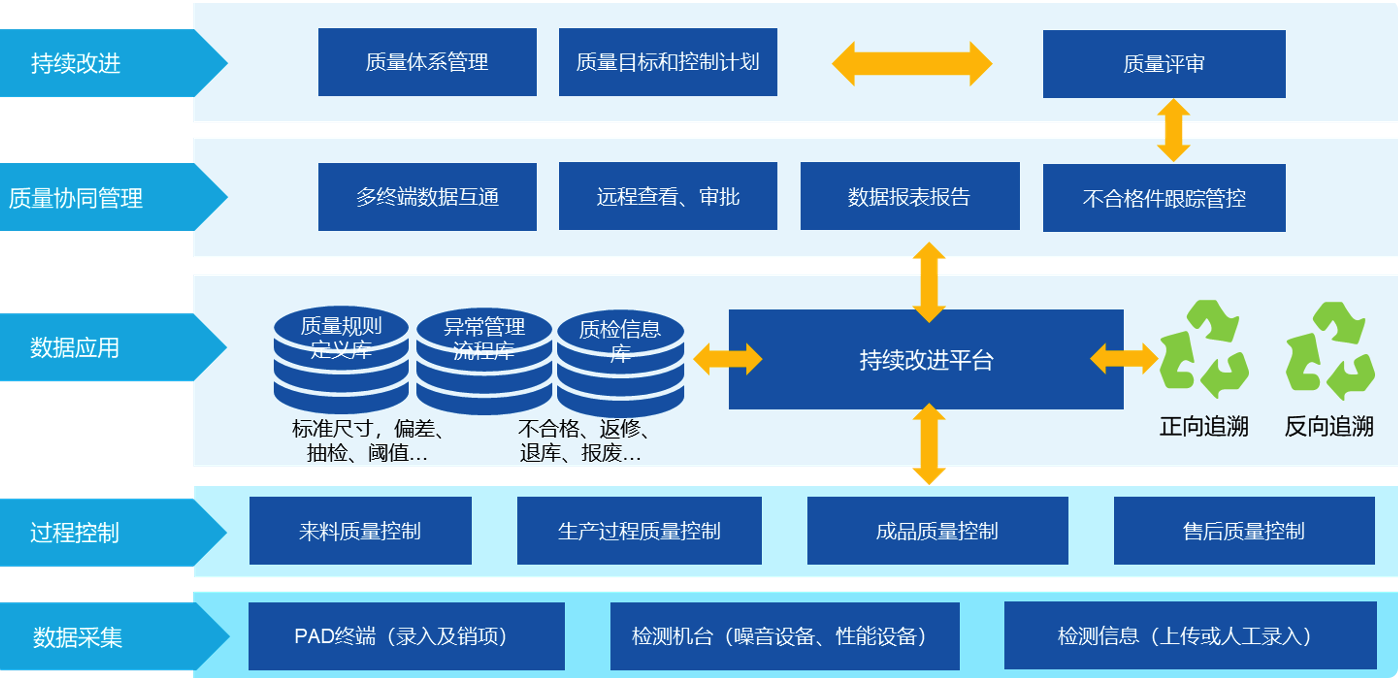

Multiple convenient data collection methods, manual and networked, improve efficiency and accuracy

Quality problem warning upgrade system

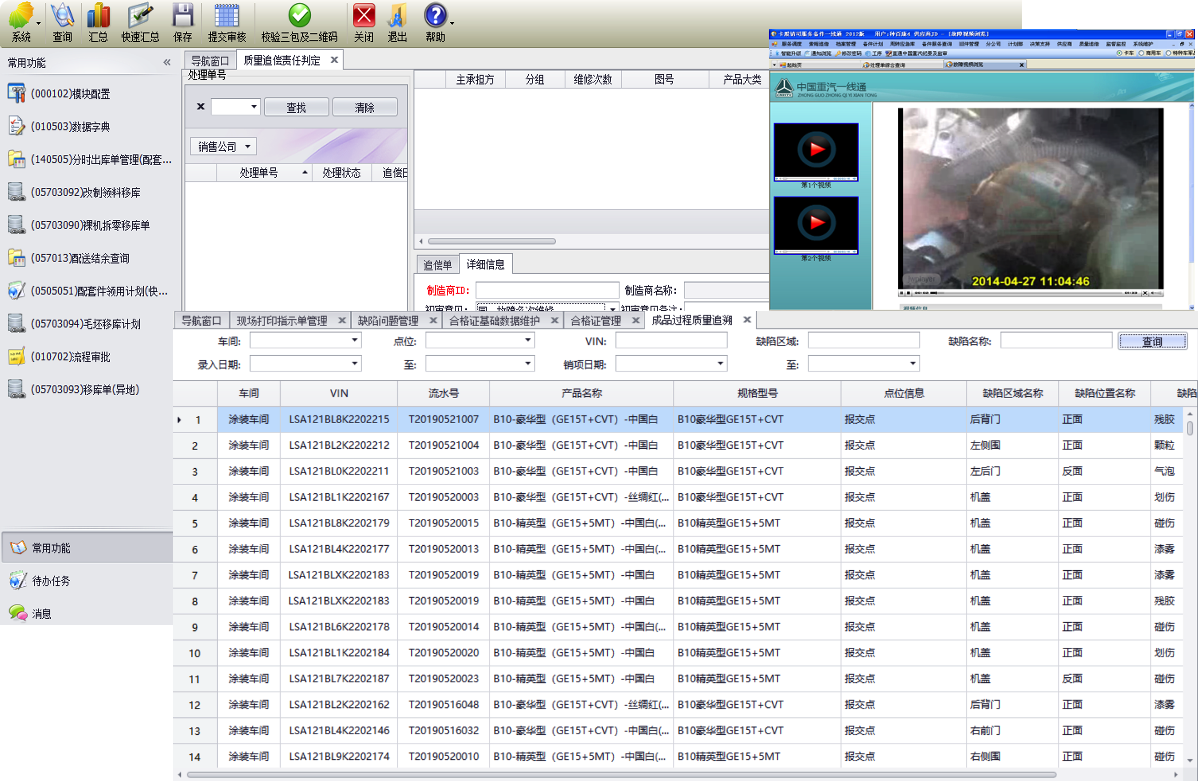

Support integration with after-sales system quality feedback, one-stop analysis and recovery of quality data

Realize comprehensive sharing of quality information and complete forward and reverse quality traceability

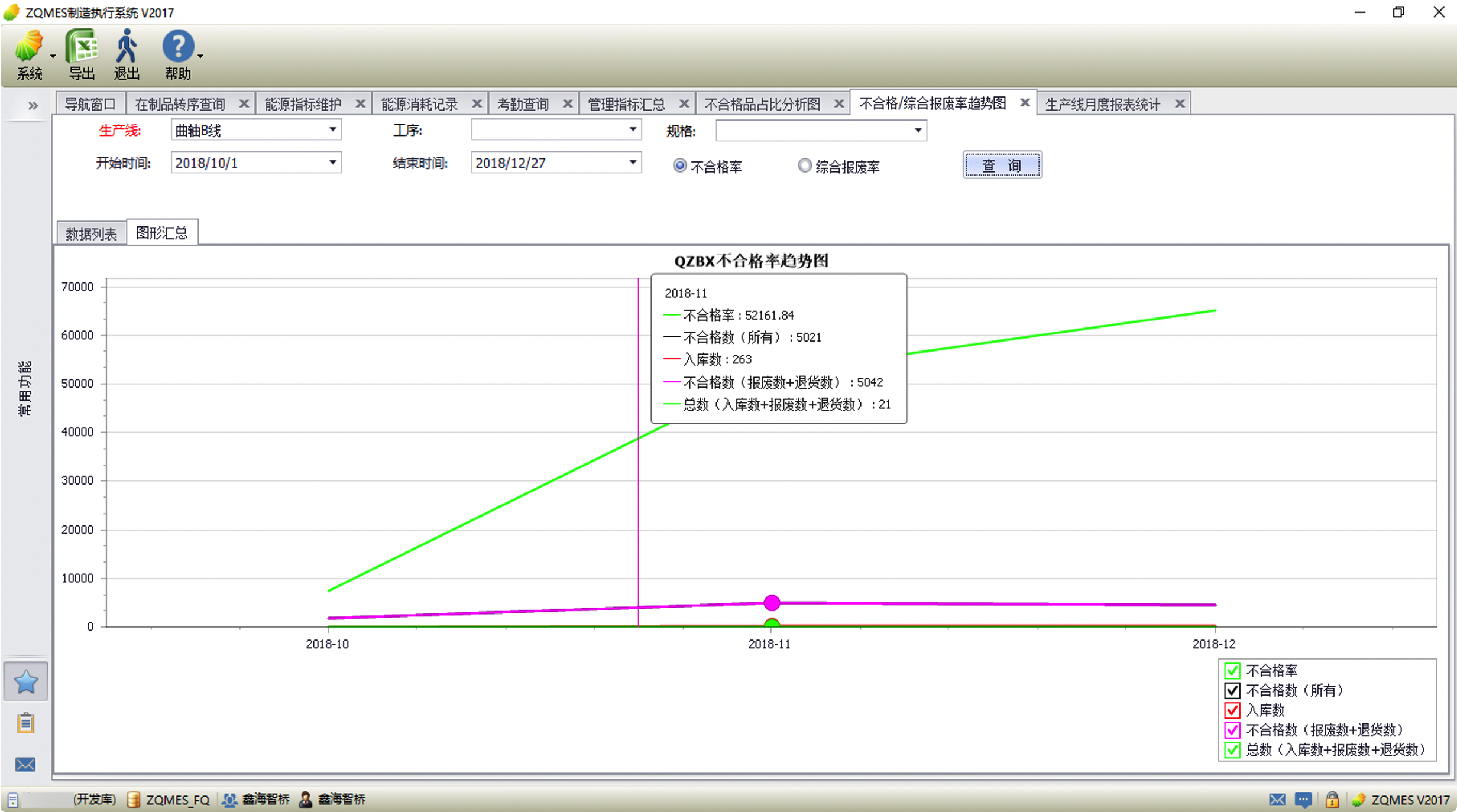

Improve process prevention and diagnostic capabilities through statistical analysis techniques such as SPC, quality control KPI, Pareto, CPK, etc

Based on real and accurate data, scientifically adjust and improve machines and processes

Real time monitoring of quality data, abnormal alarms and association with responsible persons to improve problem handling efficiency

Combined with the command cockpit application, intuitive and efficient visual management

Realize the quality management of the entire production and manufacturing process, including incoming material quality inspection, process quality inspection, finished product quality inspection, and after-sales quality

Establish a standard quality system and implement production process control based on quality dimensions

Real time analysis and display of quality KPIs, identifying quality issues and developing quality solutions

1883D6D19D79454E9B3FA44C8F7F50F7.png)