The digital capability support for large-scale customization in the automotive industry enables rapid response to complex and ever-changing market demands

Based on OTD planning system, real-time response and delivery time for end-to-end orders

Group level architecture, easily adaptable to complex operational environments with multiple factories and bases

Intelligent scheduling algorithm, accurately meeting the production scheduling and resource optimization of a single factory

Standard system integration interfaces (ERP, MES, etc.) enable seamless transmission and sharing of information

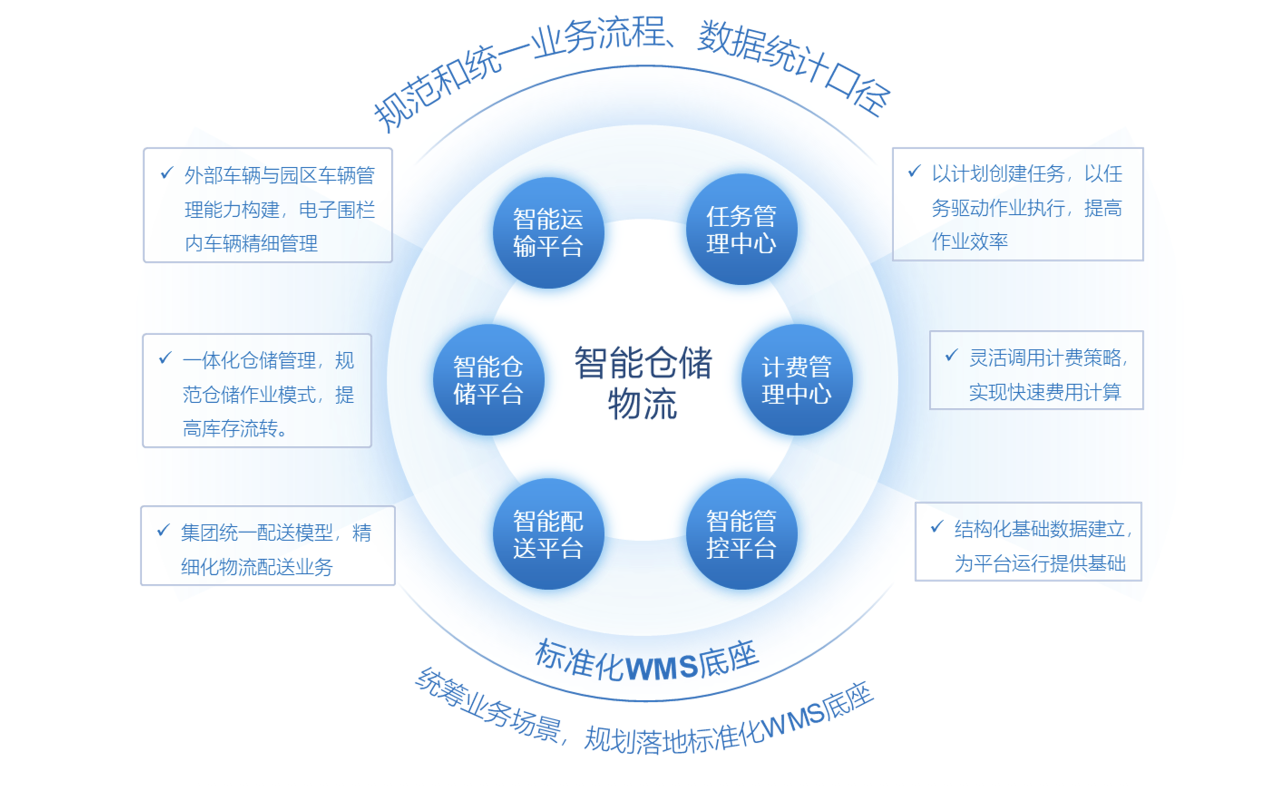

Integrate various scenarios and formats of warehousing business in the automotive industry (flat storage, shelving, vertical storage, etc.), covering multiple logistics business models (JIT/JIS/KANBAN/SPS, etc.)

Establish a standardized warehousing and logistics operation platform with the goal of achieving the best business order and economic benefits

Optimize time of use and batch delivery to reduce material backlog in line-side warehouses

Collaborate with suppliers and third-party warehouses (3PL) to achieve rapid collaboration in the procurement and distribution process

Improve the ability to adapt to production changes and create favorable conditions for on-time logistics

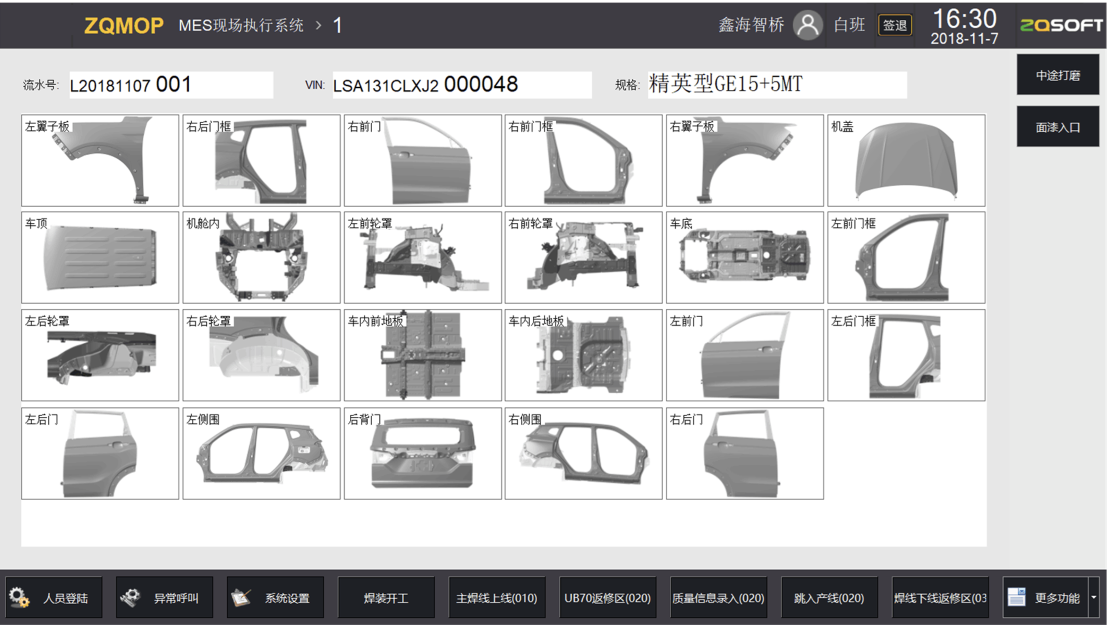

To cope with the highly customized trend in the industry, support the one vehicle one BOM model, and accurately transmit configuration information

Meet the requirements of the automotive industry for process data and switching information to be directly connected to the workshop, ensuring accuracy and consistency

Meet the control and management requirements for special and critical processes under the IATF16949 system

Implement data collection of vehicle location information to reflect real-time production status of vehicles

Four major workshops - data collection during the inspection process, and construction of a comprehensive vehicle file

Implement unified control across multiple organizations and remote locations, with management instructions directly delivered to the site

Equipment networking and group control to improve equipment efficiency: automatic command issuance, real-time status monitoring, process error prevention control, quality trend warning, intelligent fault diagnosis

Digital device mirroring model: KPI system, obtaining device KPI indicators and conducting statistical analysis

Adapt to multiple device interface protocols and data source types

Energy consumption statistics and cost analysis; Scientific prediction and optimization of indicators

Machine processing equipment, assembly equipment, detection equipment, experimental equipment, storage equipment, transportation equipment, energy equipment and other comprehensive interconnection edge computing to open up the interaction between equipment and equipment

Compliant with automotive industry quality traceability system regulations, integrating quality data from different stages

Closed loop management of quality issues, automatic data collection, automatic alarm and feedback for anomalies

ANDON system, responsible person for real-time transmission of workstation abnormal information on the large screen and SMS

Automatic collection of process quality data, one vehicle per file, establishing a complete vehicle quality file

Isolation and control of defective products, handling issues in a timely manner to avoid large-scale product recalls or customer complaints

1883D6D19D79454E9B3FA44C8F7F50F7.png)