Front end (execution end)

With lightweight, convenient, and efficient as the core, we recommend mobile phones,PDA

Information (transmission end)

Using television,LED,ensure logistics drives information transmission efficiency

Backend (Analysis End)

Using PC, conference tablet, etc. to achieve data query and analysis

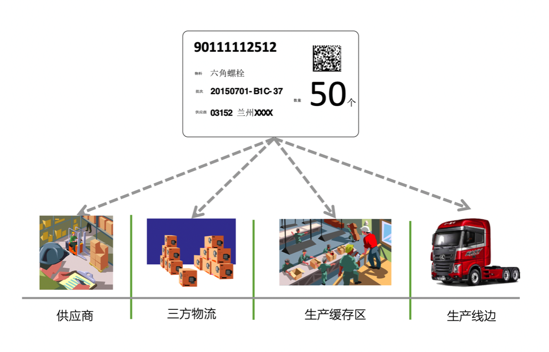

Establish scientific, standardized, and unified barcode rules

Implement one code to the end and improve overall work efficiency

Control the production and logistics processes through various barcode labels

Digital warehouse management enables personnel to perform "foolproof operations" and improves the efficiency of inbound and outbound warehousing

More accurate MRP calculation to improve the accuracy of goods procurement

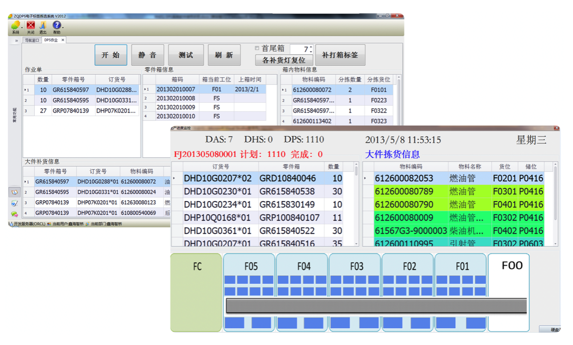

DPS electronic sorting improves sorting accuracy

Multidimensional pull management to improve pull accuracy

Picking tasks for process control, displaying real-time job progress

Light up guidance for picking operations, highly automated

Track and record every step of the picking process

Standardize warehouse shelf layout, improve packaging quality, and strengthen parts protection

The ZQ DPS system automatically prompts daily BOM changes

Real time changes in virtual parts are reflected in sorting, and BOM can be flexibly modified

Shift management, fixed personnel positions for system operations

Storage location management, where storage locations correspond to materials and have priority levels

One code to the end, full traceability of materials and traceability of operators

1883D6D19D79454E9B3FA44C8F7F50F7.png)