Resource optimization and allocation: Through intelligent scheduling and capacity analysis, reduce equipment idle and improve delivery timeliness

Full process traceability and control: Real time collection of production data, support for second level traceability of quality abnormalities, and improve the efficiency of problem localization

Seamless collaboration system: breaking down departmental data barriers, reducing communication costs through system integration, achieving digital management of workshops, and efficient linkage

Optimization of Exception Management: By monitoring device status in real-time, we can reduce production downtime and save quantifiable costs

Total factor data collection: By using IoT technology to map the full dimensions of human, machine, material, method, environment, and measurement data, the production process can be 100% digitized.

Cross system data fusion: Based on ESB bus technology, integrate ERP, PLC and other system data, eliminate data silos, and form an enterprise data asset pool.

Intelligent analysis and decision-making: using machine learning algorithms to construct predictive models, realizing intelligent scenario applications such as equipment failure warning and capacity bottleneck prediction.

Data driven process: Each position obtains customized production data and analysis reports in real-time, achieving full process information connectivity from order issuance to completion and offline

Performance automation management: Based on production data collection and performance rules, automatically calculate employee performance wages, and improve management efficiency by more than 30%.

Task closed-loop management: supports one click task issuance, execution feedback, and progress push, reducing production response time by more than 50%.

Integration of Management and Technology: Based on business process reengineering, incorporating lean thinking, optimizing production pace and reducing waste through digital means.

Data driven continuous improvement: Based on analysis models such as equipment OEE and capacity load, provide quantitative basis for lean improvement and promote continuous efficiency improvement.

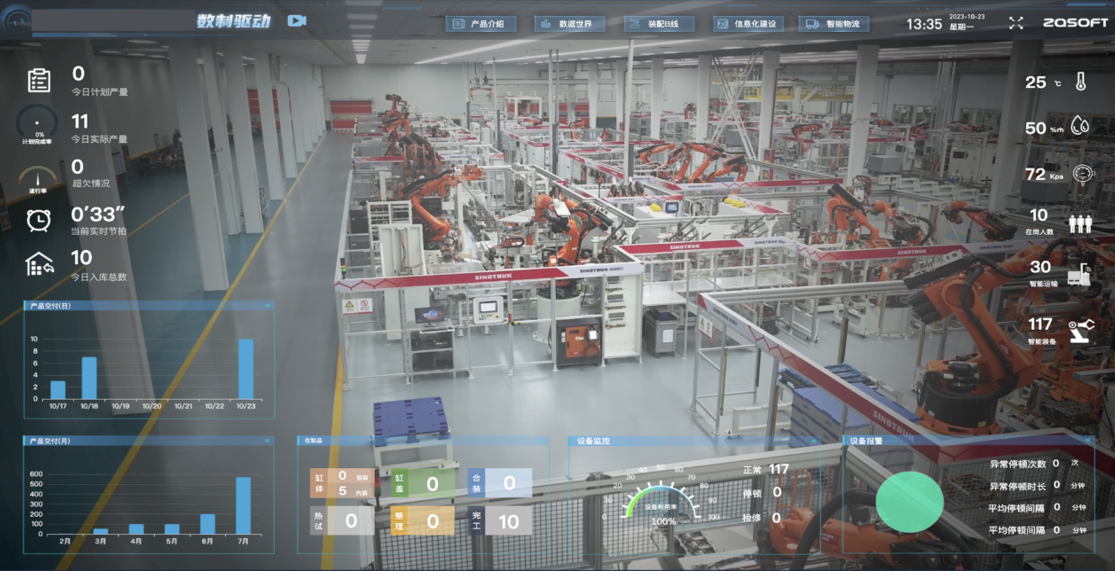

Visual management center: The workshop cockpit presents core indicators such as plan achievement rate, equipment operation rate, and quality qualification rate in real-time, assisting in management decision-making.

1883D6D19D79454E9B3FA44C8F7F50F7.png)