Centralized control of multiple factories - controllable factory operations to avoid the management is out of the reach

Regional Capacity Collaboration - Real time Visualization of Capacity, Strengthening Risk Adjustment Capability

Intelligent production command - reducing human intervention and solving the problem of overseas employment

Full stack business coverage - low code, high availability, integrate the manufacturing operation links

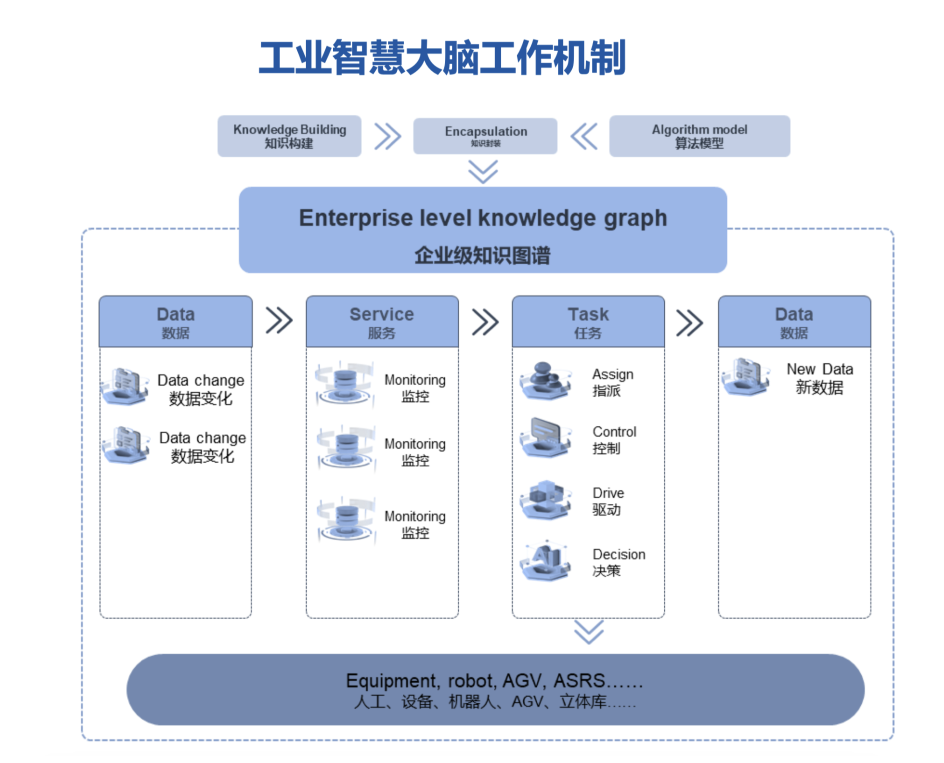

Introducing Industrial Intelligence Brain: Accelerating the Leap Forward of Manufacturing Systems towards Self Perception, Self Analysis, Self Decision Making, and Self Execution.

Real time data triggers execution decisions: automatically identifies personalized order status, adapts processes, organizes manufacturing resources to complete production operations, material distribution, and quality inspection

System command replaces human brain work: reduces human error and reliance on skilled workers, and lowers labor costs.

Standardization: significantly improves the output efficiency and quality stability of products.

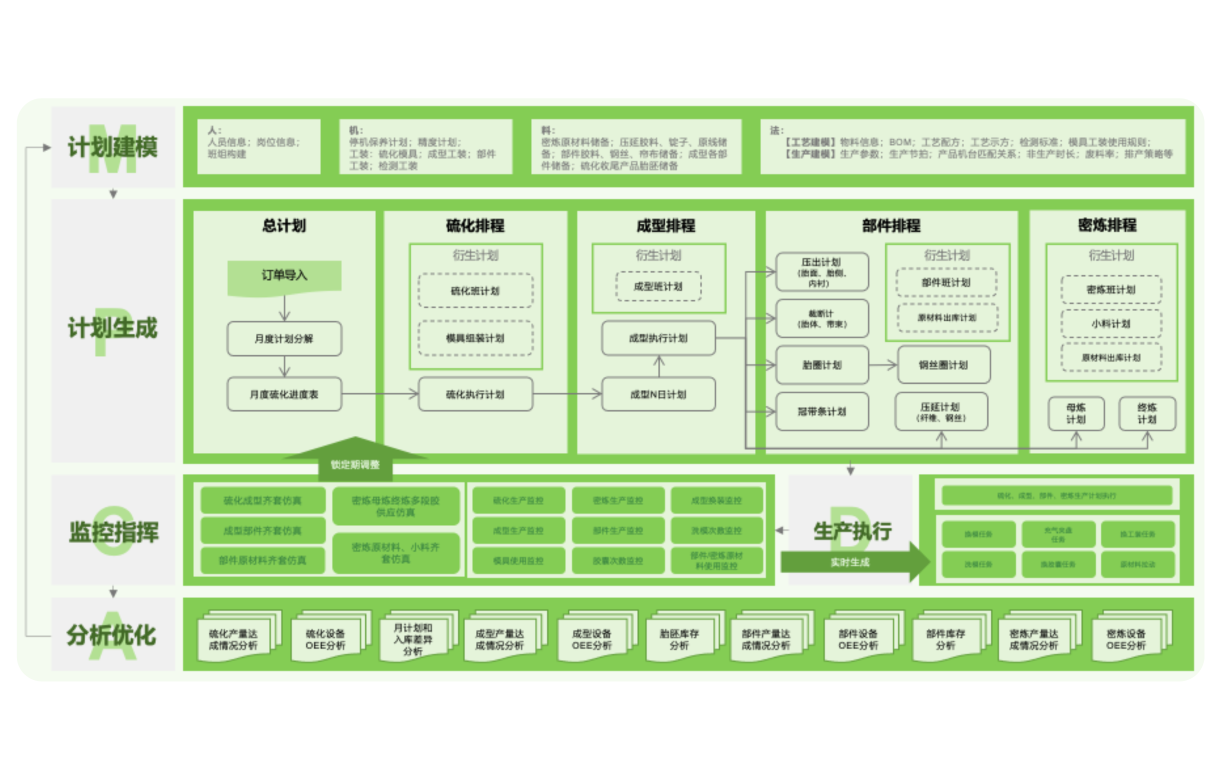

Integrating manufacturing execution system, real-time coordination between planning and production execution, achieving a closed-loop planning execution system;

Based on the real-time status of the production site, flexible and dynamic resource allocation and scheduling are used to respond to unexpected situations such as equipment failures

Maximizing the utilization of key resources and increasing production line output by 20%

Avoid excessive reliance on manual experience for enterprise production scheduling and shorten the scheduling cycle

Strengthen agile response and rapid delivery capabilities to reduce resource conflicts and waste

Tire Manufacturers can realize the digital management of manufacturing processes in multiple factories worldwide, and improve the standardization of production processes

Explore the potential of digitalization and achieve collaborative management of production progress, quality information, equipment information, material information, alarm information, tooling and mold information, cost and performance information, etc

Through real-time data, trigger execution decisions to improve efficiency and help Tire Manufacturers reduce waste

Provide real-time visibility of workshop operation, process execution and resource management for Tire Manufacturers

Provide solutions compatible with multiple logistics modes for the Tire Industry, and support traditional factory manual mode and new factory automation mode

Based on the principles of lean manufacturing, combined with planning, scheduling, and manufacturing execution, optimize logistics efficiency and eliminate waste

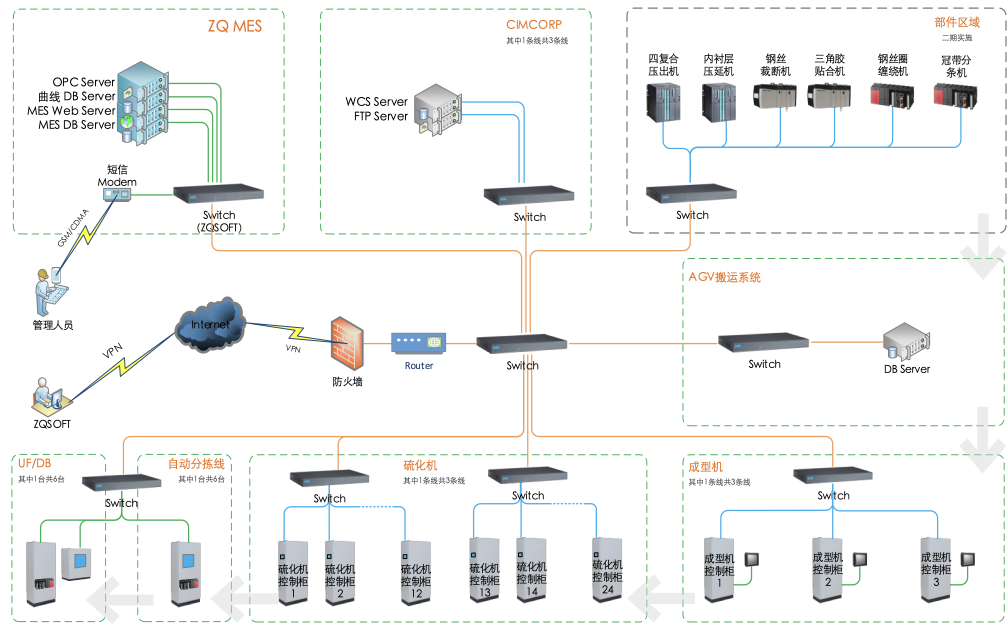

Through the IOT Internet of Things platform, the integration of automated systems such as AGV material handling systems, stacking systems, sorting and palletizing systems, EMS aerial conveying systems, and vertical warehouse systems is achieved, enabling efficient collaboration

Abstract modeling of logistics scenarios, adapting to changes in production logistics execution modes, seamlessly upgrading from manual mode to automatic mode

Standard protocol specifications+IoT suite as the core, creating standard industry equipment interface

Building an integrated intelligent industrial control system with loosely coupled interface management mode, minimalist architecture, and software definition

Command devices through software to enhance the intelligence level of traditional devices and improve device utilization

Integrated development efficiency has increased by more than 3 times, and development costs have been reduced by 30%

Integrate equipment data and experimental data to achieve automatic data collection and analysis, and improve detection efficiency

Resolve difficulties such as multiple report styles and cumbersome management, and bridge the gap between business and data flows

Structured data, real-time linkage of whole process data such as raw material analysis, process parameters, and testing results

Assist in innovative research and development, and accumulate data assets for Tire Manufacturers

Nearly 20 tire factories have delivered 100% of their digital projects

Experienced in implementing overseas projects, with regional coverage in Southeast Asia, Africa, and Europe

With rich experience in the industry, the company's experts were invited to participate in the preparation of the "15th Five-Year Plan" development plan for the Tire Industry organized by the China Rubber Industry Association and the Tire Branch.

1883D6D19D79454E9B3FA44C8F7F50F7.png)