轴承质量在于合套游隙值符合工艺设计规范,如何达到合规游隙值、生产出高质量、高精度轴承的关键在于合套的匹配性符合游隙值工艺规范要求。

The quality of bearings depends on the fit clearance value meeting the process design specifications. The key to achieving compliant clearance values and producing high-quality, high-precision bearings lies in the fit compatibility meeting the clearance value process specification requirements.

游隙值指轴承内外圈的相对位移量,具体来说就是在一定条件下轴承内部各个部件的空隙大小。游隙值直接影响轴承运行精度、噪声水平、润滑状况和使用寿命。

The clearance value refers to the relative displacement between the inner and outer rings of a bearing, specifically the size of the clearance between various components inside the bearing under certain conditions. The clearance value directly affects the operating accuracy, noise level, lubrication condition, and service life of the bearing.

轴承游隙值的大小将直接影响轴承的工作寿命乃至整个设备的运行稳定性;过大的游隙可能导致振动和噪音增加,降低承载能力;过小的游隙则会增加摩擦,产生更多热量,加速磨损和热损坏。那么如何将轴承内圈、外圈、滚动体组合达到游隙值工艺要求范围是轴承制造装配时首要目标。

The size of the bearing clearance value will directly affect the working life of the bearing and even the operational stability of the entire equipment; Excessive clearance may lead to increased vibration and noise, reducing load-bearing capacity; A too small clearance will increase friction, generate more heat, accelerate wear and thermal damage. So, the primary goal in bearing manufacturing and assembly is to achieve the required clearance range for the combination of the inner and outer rings and rolling elements of the bearing.

ZQMES为轴承企业提供的一套内嵌MES中的智能合套模块将解决不同品类轴承装配合套,制造生产部门如何进行配圈合套以达到不同轴承类的游隙值工艺要求。

ZQMES provides a set of intelligent fitting modules embedded in MES for bearing enterprises, which will solve the assembly and fitting of different types of bearings, and how the manufacturing and production departments can perform ring fitting and fitting to meet the clearance value process requirements of different bearing types.

合套规则定义

Definition of Integration Rules

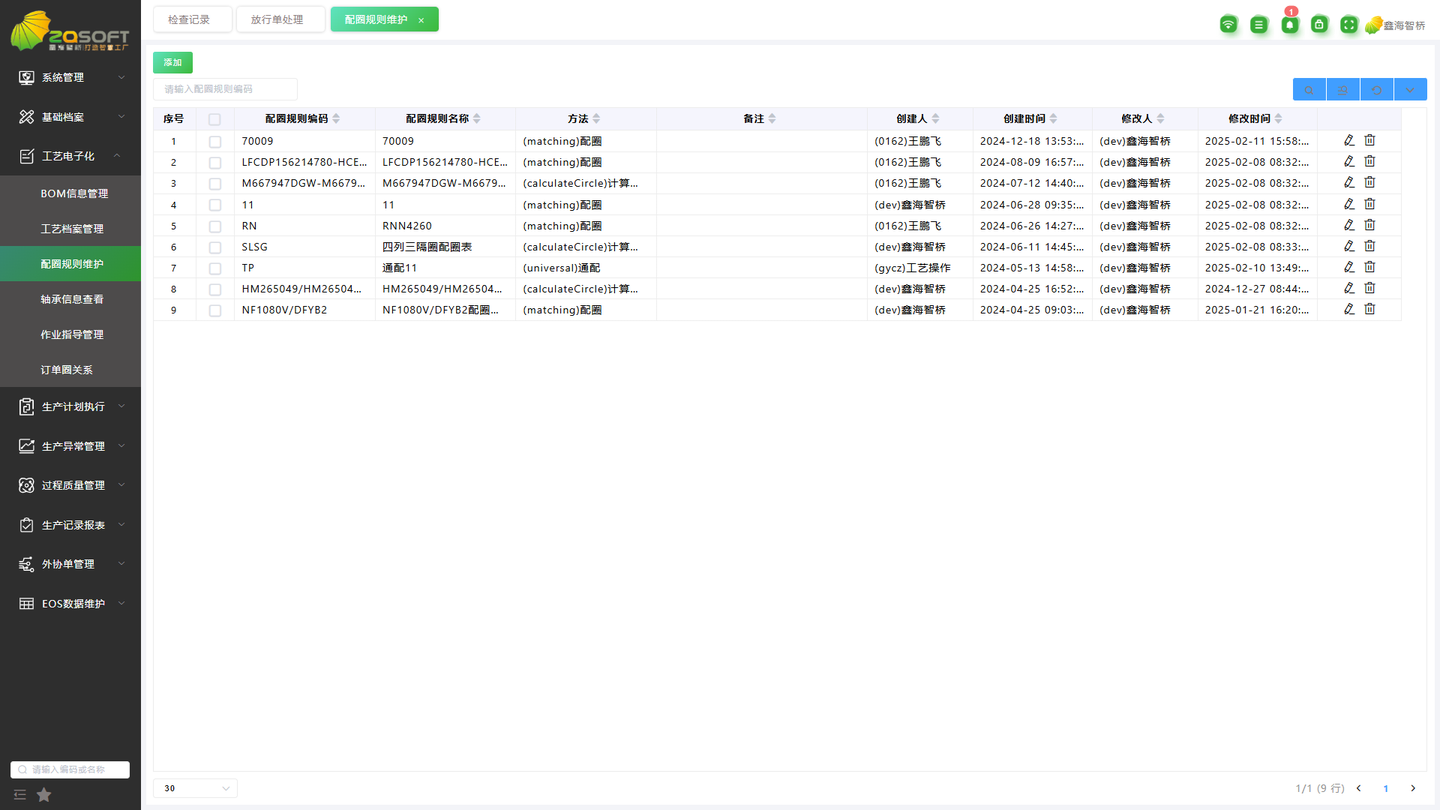

通过ZQMES配圈规则维护模块,将轴承合套规则转化为计算机合套逻辑,充分定义不同品类轴承合套时游隙值计算逻辑,并结合车间工单自动调用合适的合套规则逻辑,实现合套计算的自动化。

By using the ZQMES ring fitting rule maintenance module, the bearing fitting rules are transformed into computer fitting logic, fully defining the calculation logic of clearance values when fitting different types of bearings. Combined with workshop work orders, the appropriate fitting rule logic is automatically called to achieve automation of fitting calculation.

内外圈尺寸采集

Collection of inner and outer circle dimensions

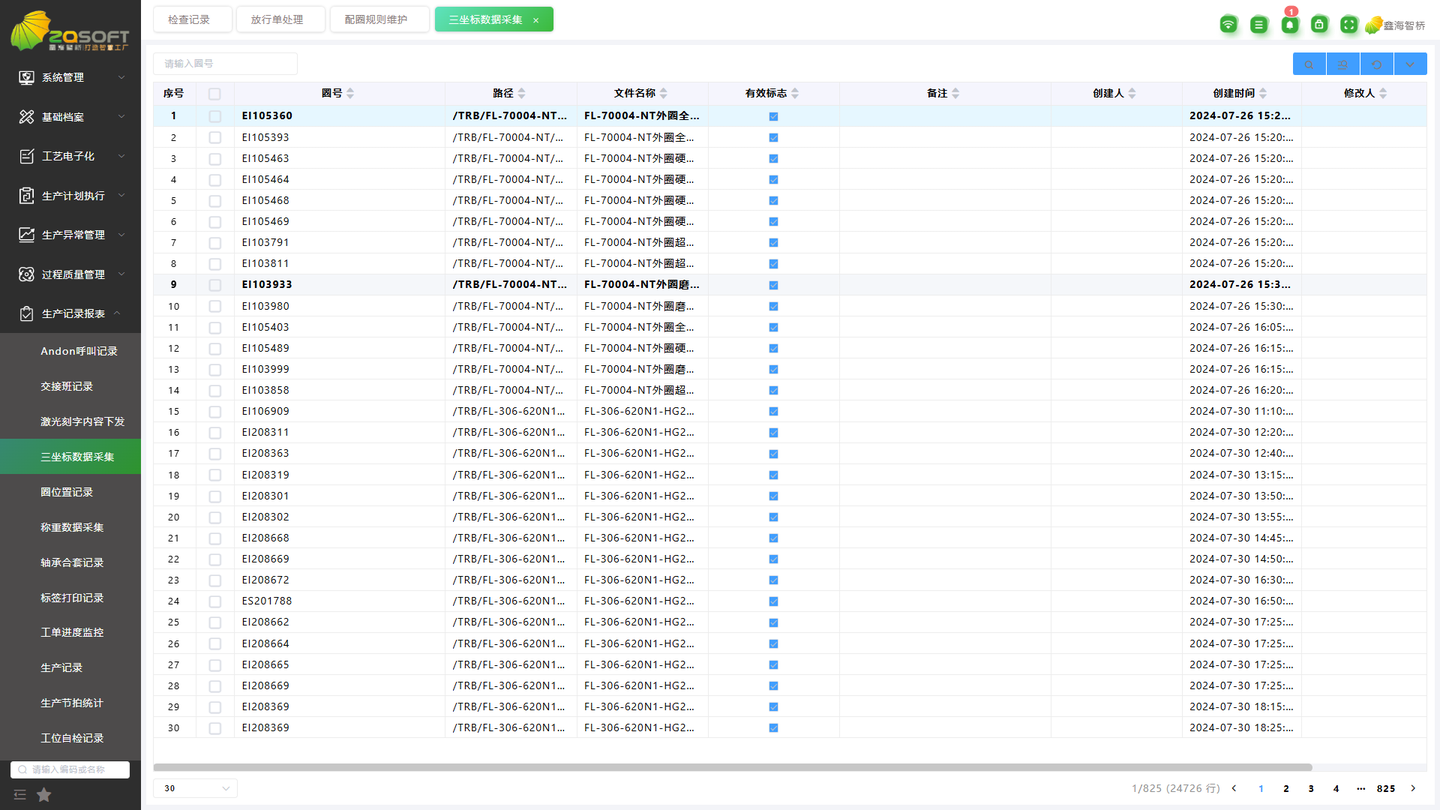

ZQMES与三坐标设备集成,获取三坐标检测报告,解析内外圈加工后的尺寸信息,形成内外圈三坐标检测记录。

ZQMES is integrated with three coordinate equipment to obtain three coordinate detection reports, analyze the dimensional information of the inner and outer rings after processing, and form three coordinate detection records for the inner and outer rings.

智能合套计算

Intelligent integrated computing

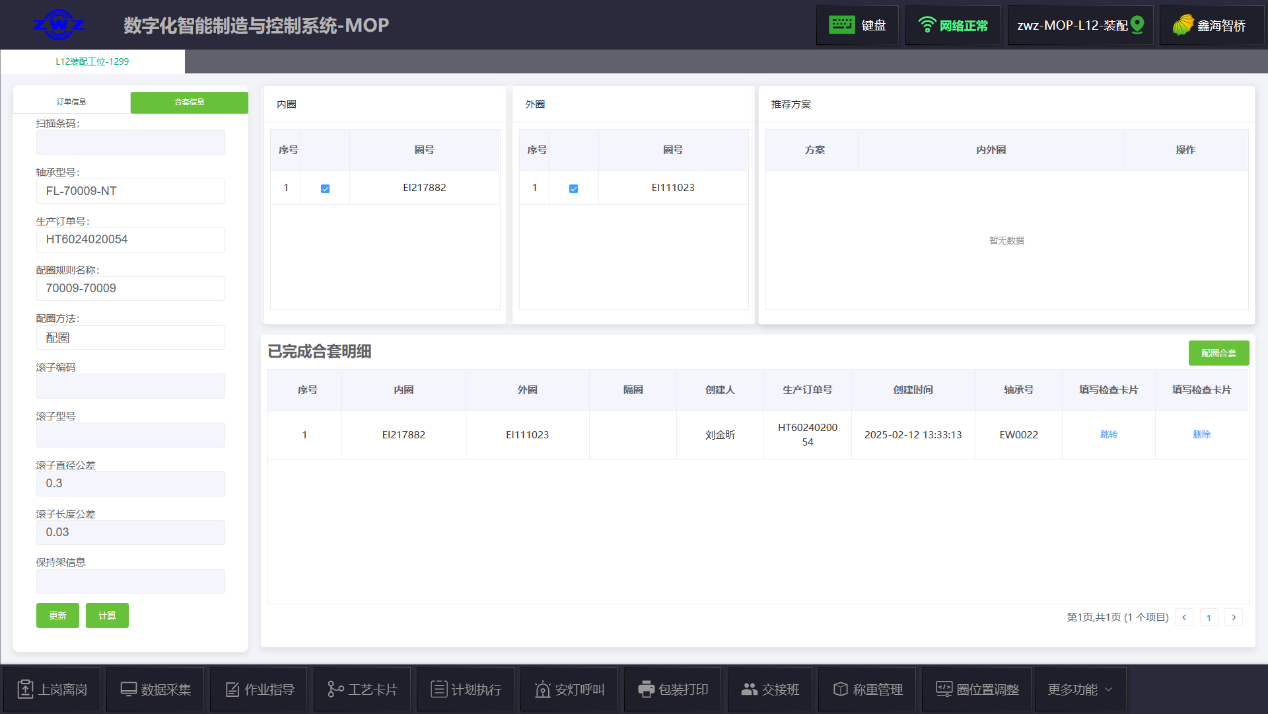

ZQMES下发装配工单至装配工位,结合产品信息自动调用合套规则逻辑,自动抓取内外圈合套逻辑计算项,结合企业对于轴承精度要求进行内外圈组别划分,将实际生产的内外圈进行分组存放。

ZQMES issues an assembly work order to the assembly station, automatically calls the fitting rule logic based on product information, automatically captures the calculation items of the inner and outer ring fitting logic, and divides the inner and outer ring groups according to the enterprise's requirements for bearing accuracy. The actual produced inner and outer rings are stored in groups.

装配合套指示

Assembly and fitting instructions

装配现场结合扫描装置,获取任意内圈/外圈数据,系统自动计算符合游隙值工艺要求的外圈/内圈的尺寸,并进行组别匹配,给出配圈指导,指引作业者进行装配合套。

By combining scanning devices on the assembly site, any inner/outer ring data can be obtained. The system automatically calculates the size of the outer/inner ring that meets the clearance value process requirements, and performs group matching to provide guidance on ring fitting, guiding operators to assemble and fit.

ZQMES的智能合套模块实现了轴承制造装配合套智能化、自动化,有效的提高了装配的效率和轴承精度。

The intelligent fitting module of ZQMES has achieved intelligent and automated bearing manufacturing and assembly fitting, effectively improving assembly efficiency and bearing accuracy.

总结

summarize

随着智能制造的快速发展,企业面临着前所未有的机遇与挑战。在这样一个数字化转型的大潮中,如何通过创新技术提升生产效率、优化管理流程,成为了每个企业亟待解决的重要问题。智能制造作为产业升级的关键,已经成为推动行业发展和企业竞争力提升的重要引擎。

With the rapid development of intelligent manufacturing, enterprises are facing unprecedented opportunities and challenges. In this wave of digital transformation, how to improve production efficiency and optimize management processes through innovative technology has become an important issue that every enterprise urgently needs to solve. Intelligent manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing enterprise competitiveness.

在这一背景下,鑫海智桥凭借其深厚的技术积淀和丰富的行业经验,持续为客户提供领先的物联网技术、智能制造解决方案以及MES/MOM/APS系统等。我们的解决方案涵盖从生产现场到企业管理各个层面,帮助企业在提升生产效率、降低成本的同时,实现更加灵活和智能的生产模式。

In this context, ZQSOFT continues to provide customers with leading Internet of Things technology, intelligent manufacturing solutions, MES/MOM/APS systems, etc. with its profound technology accumulation and rich industry experience. Our solutions cover all levels from production sites to enterprise management, helping companies achieve more flexible and intelligent production modes while improving production efficiency and reducing costs.

作为行业的技术领跑者,鑫海智桥不断推动数字化转型与智能制造的深度融合,致力于为全球制造业提供最具竞争力的解决方案。我们将继续秉持“创新驱动、智能制造”的核心理念,助力客户在激烈的市场竞争中脱颖而出,走在行业发展的前沿。

As a technology leader in the industry, ZQSOFT has continuously promoted the deep integration of digital transformation and intelligent manufacturing, and is committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of "innovation driven, intelligent manufacturing", helping customers stand out in fierce market competition and stay at the forefront of industry development.

如果您希望了解更多关于智能制造的资讯,或是想探讨如何通过数字化转型提升企业效率,欢迎随时联系我们。鑫海智桥将竭诚为您提供全方位的技术支持与服务,与您携手共进,共同迈向智能制造的新时代。

If you would like to learn more about intelligent manufacturing or explore how to improve enterprise efficiency through digital transformation, please feel free to contact us at any time. ZQSOFT will wholeheartedly provide you with all-round technical support and services, and work together with you to enter a new era of intelligent manufacturing.