Digital capabilities support large-scale customization in automotive, enabling fast response to market changes.

OTD-based system ensures real-time, end-to-end order and delivery response.

Group-level architecture adapts to multi-factory, multi-base operations.

Intelligent scheduling meets single-factory production and resource optimization needs.

Standard interfaces (ERP, MES) enable seamless data sharing and integration.

Integrate diverse automotive warehousing scenarios (flat, shelving, vertical) and logistics models (JIT/JIS/KANBAN/SPS).

Build a standardized logistics platform to optimize business order and economic benefits.

Optimize usage time and batch delivery to reduce line-side material backlog.

Enable fast collaboration with suppliers, 3PLs, and in procurement and distribution.

Enhance adaptability to production changes, ensuring on-time logistics.

Support one-vehicle-one-BOM to accurately transmit configuration data for high customization.

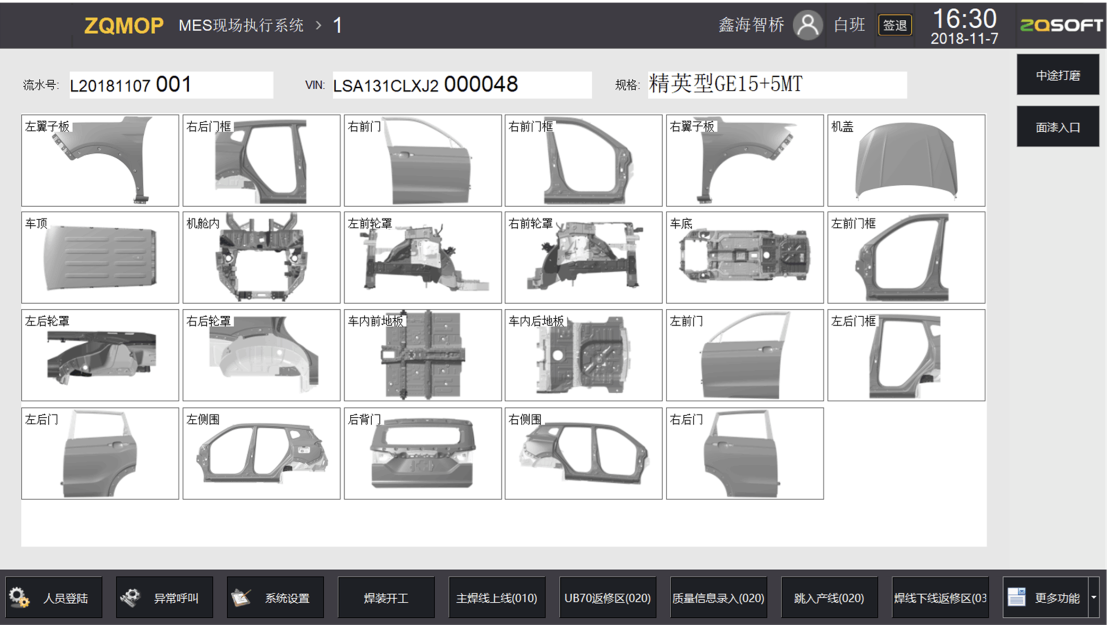

Ensure accurate, consistent process and switching data directly connected to workshops.

Meet control requirements for critical processes under IATF16949 standards.

Collect vehicle location data to reflect real-time production status.

Capture inspection data across four major workshops to build complete vehicle files.

Enable unified control across multiple sites, with direct on-site instruction delivery.

Enable equipment networking and group control for efficiency: auto commands, real-time monitoring, error prevention, quality alerts, and fault diagnosis.

Use digital device mirroring for KPI tracking and analysis.

Support diverse interface protocols and data sources.

Provide energy consumption stats and cost analysis with predictive optimization.

Achieve edge computing-based interconnection across machining, assembly, testing, storage, transport, and energy equipment.

Compliant with automotive industry quality traceability system regulations, integrating quality data from different stages

Closed loop management of quality issues, automatic data collection, automatic alarm and feedback for anomalies

ANDON system, responsible person for real-time transmission of workstation abnormal information on the large screen and SMS

Automatic collection of process quality data, one vehicle per file, establishing a complete vehicle quality file

Isolation and control of defective products, handling issues in a timely manner to avoid large-scale product recalls or customer complaints