In modern manufacturing, Manufacturing Execution System (MES) plays a key role, and material information collection is one of its core functions.MES achieves precise material information collection through various technological means, providing strong support for the production process.

The main way for MES to collect material information

1、Application of Automatic Identification Technology

Barcode technology is a common way for MES to collect material information.When materials are stored, staff attach a unique barcode to each batch of materials, which includes key information such as material name, specifications, quantity, and production date.When materials are transferred to the production process, workers use scanning devices to read barcodes, and the MES system can obtain real-time dynamic data such as the time and process of material input into production.This method is low-cost and easy to implement, and is widely used in various manufacturing industries.Barcode scanning: Record material batches, specifications, and other information through one-dimensional/two-dimensional codes

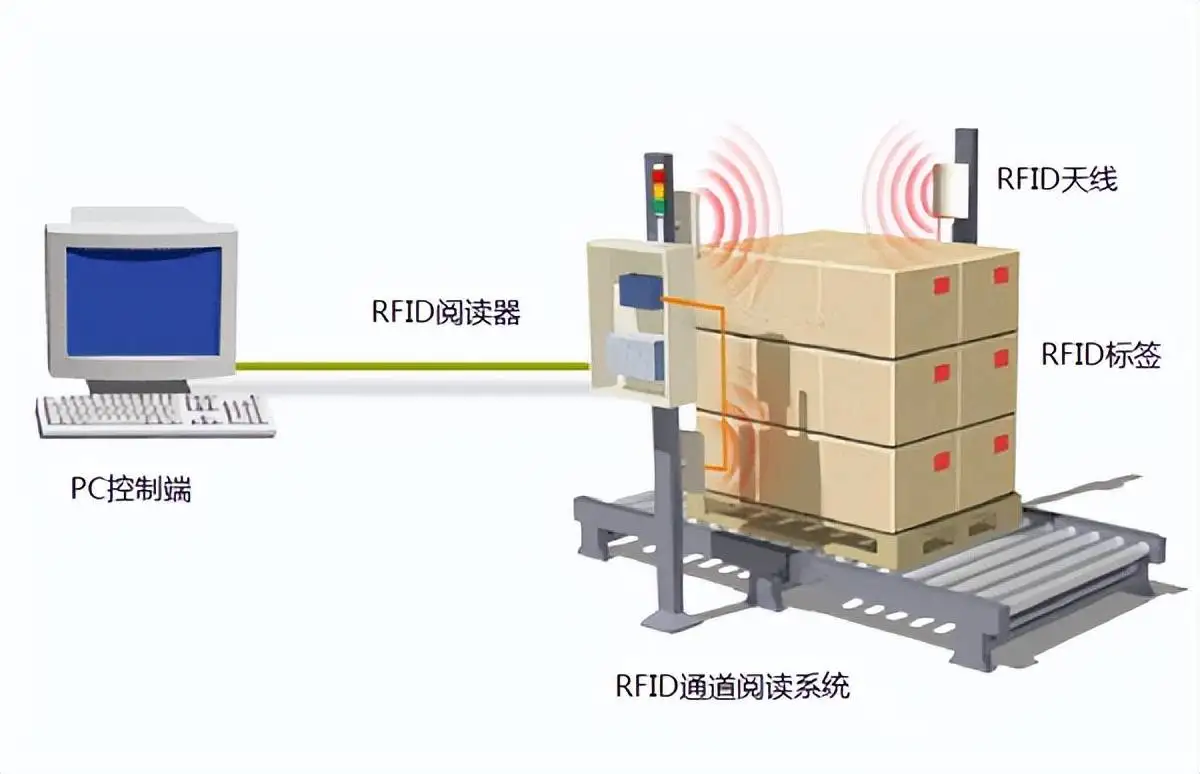

Another advanced material information collection technology is radio frequency identification (RFID).Unlike barcodes, RFID tags can be read without physical contact.In complex production environments, materials with RFID tags can be automatically identified at various stages of transportation, storage, and production, and information can be quickly transmitted to MES systems.For example, in automated production lines, when materials pass through specific sensing areas, RFID readers instantly complete information collection, greatly improving data collection efficiency and reducing errors caused by manual intervention.RFID radio frequency identification: realizing non-contact and batch reading of material data

Application value of material information collection

1、Production and operation

Real time visual management: tracking material status and location throughout the process

Mistake proof and fool proof: prevent misuse, mixing and omission of materials

Accurate traceability: establish a complete material map

2、Quality control level

Batch management: precise control of material validity and FIFO

Quality Association: analyze the relationship between material attributes and product quality

Rapid recall: accurate positioning and rapid isolation of problem materials

Through the collection of material information in the MES system, enterprises can realize the full link digital management from raw materials to finished products, and lay a data foundation for intelligent manufacturing.

SUMMARY

With the rapid development of smart manufacturing, enterprises are facing unprecedented opportunities and challenges. In such a wave of digital transformation, how to enhance production efficiency and optimize management processes has become an important issue that every enterprise must address. As a key driver of industrial upgrading, smart manufacturing has become an important engine for industry development and improving enterprise competitiveness.

Against this backdrop, Xinhaizhichiao, with its profound technological expertise and rich industry experience, continues to provide leading IoT technologies, smart manufacturing solutions, and MES/MOM/APS systems to customers. Our solutions cover all aspects from the production site to enterprise management, helping businesses achieve more flexible and intelligent production models while improving production efficiency and reducing costs.

As a technological leader in the industry, Xinhaizhichiao continues to promote the deep integration of digital transformation and smart manufacturing, dedicated to providing the most competitive solutions for the global manufacturing industry. We will continue to adhere to the core concept of “Innovation Driven, Smart Manufacturing,” assisting our clients in standing out in the fierce market competition and staying at the forefront of industry development.

If you would like to learn more about smart manufacturing or discuss how to enhance your business efficiency through digital transformation, please feel free to contact us. Xinhaizhichiao is committed to providing you with comprehensive technical support and services, working hand in hand with you to embrace the new era of smart manufacturing.