In the tire manufacturing industry, the question is no longer whether to implement an MES system, but whether it can truly be used effectively. Many companies find that after MES deployment, production still relies heavily on manual coordination, data exists but does not support decision-making, and the system fails to deliver real value.

In most cases, the issue is not a lack of system functions, but a disconnect from real production scenarios. Tire manufacturing involves complex processes such as mixing, calendaring, building, and curing. With diverse formulations and strict quality requirements, effective process control and traceability are critical. Without deep integration with equipment, process parameters, barcodes, and formulation management, an MES system cannot support refined operations.

A truly practical MES should be designed around how orders are executed, how production is controlled, and how exceptions are handled. By collecting real-time production data, MES enables process transparency, full traceability, and early warning mechanisms—allowing management to shift from after-the-fact reporting to proactive control.

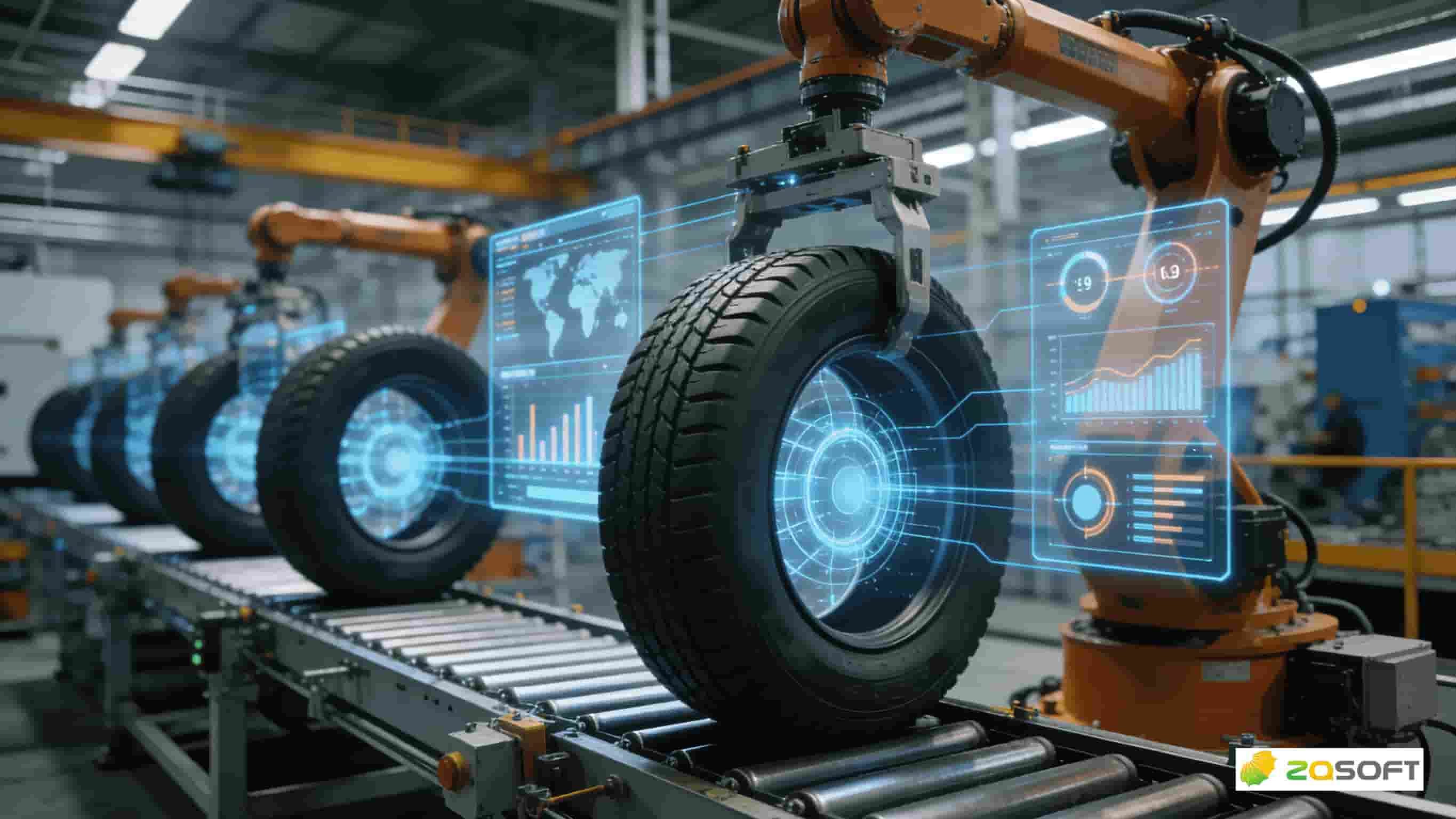

With extensive experience in the tire manufacturing sector,ZQSOFT focuses on delivering MES solutions aligned with real operational workflows. Through close integration between systems and shop-floor operations, ZQSOFT helps manufacturers improve efficiency and reduce quality risks without increasing headcount, laying a solid foundation for intelligent manufacturing.

1883D6D19D79454E9B3FA44C8F7F50F7.png)