For many years, production management in tire factories has relied heavily on experience. Schedule adjustments are handled manually, and on-site judgment plays a major role in exception handling. While this approach may work in small-scale, low-complexity environments, risks increase significantly as order diversity grows and delivery timelines tighten.

As production scale expands and operations become more complex, experience-based management alone is no longer sufficient. Management teams require accurate, real-time data to understand capacity utilization, identify bottlenecks, and make timely adjustments.

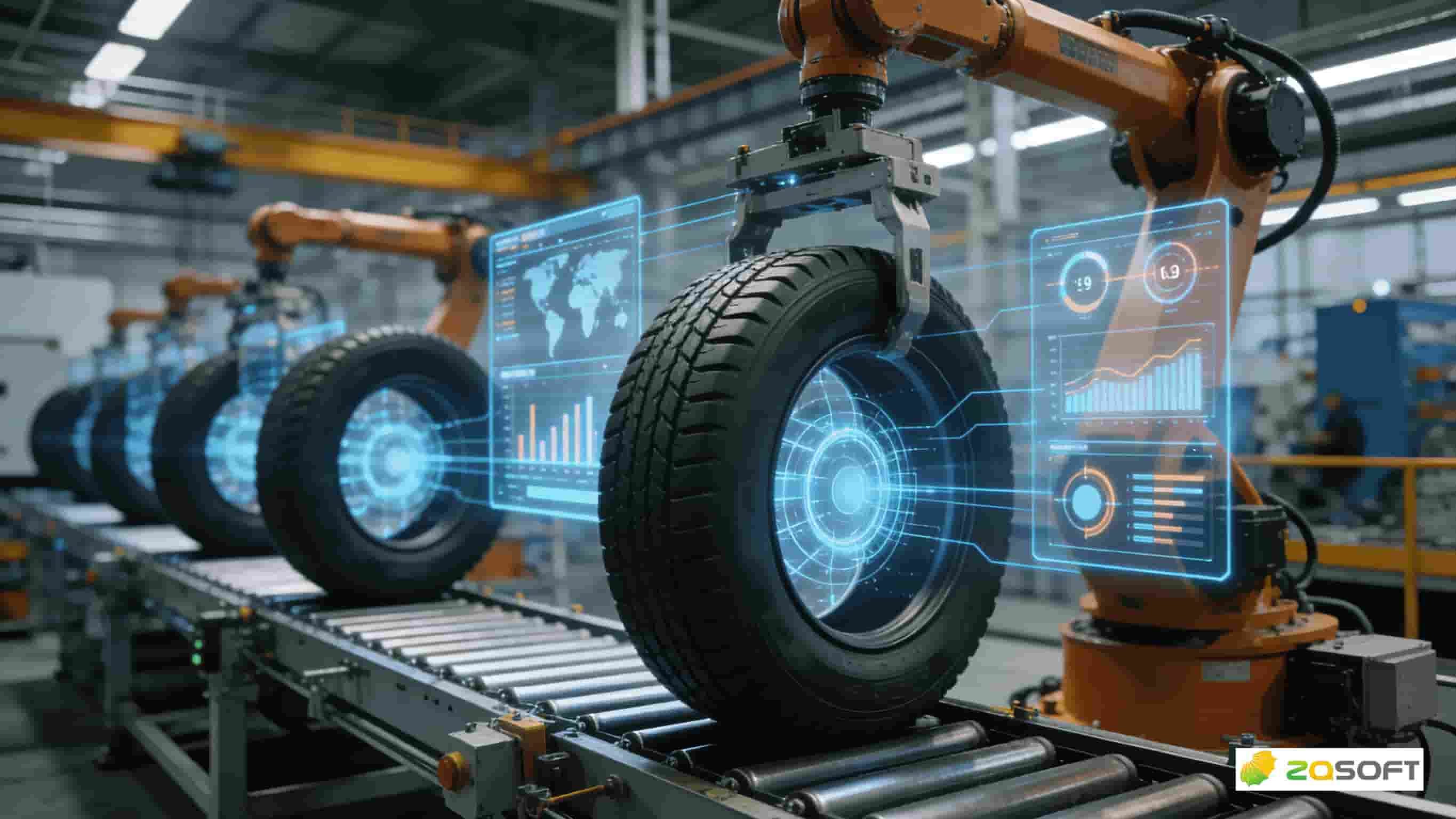

Data-driven management models centered on systems such as MES and APS are becoming essential for tire manufacturers. By integrating planning, production, quality, and equipment data, companies gain clear visibility into execution status and deviations—allowing decisions to be based on facts rather than assumptions.

In real-world projects, ZQSOFT has found that data-driven transformation does not succeed simply by deploying systems. True value is created when systems are deeply integrated with business processes and data becomes part of daily operations for both frontline staff and management. Only then can digital transformation deliver sustainable results.

1883D6D19D79454E9B3FA44C8F7F50F7.png)