In modern manufacturing, the Manufacturing Execution System (MES) serves as a crucial bridge connecting the enterprise planning layer with the production control layer, playing a pivotal role in achieving process quality control. ZQ-MES conducts comprehensive and real-time quality monitoring and management of the production process through data-driven approaches, process optimization, and intelligent decision-making, ensuring the stability and consistency of product quality. Its specific implementation process encompasses multiple key aspects:

Establish precise quality standards and process specifications

Based on product design requirements and corporate quality objectives, the ZQ-MES system refines and digitizes quality standards and process specifications. A detailed quality standard database is established within the system, specifying quality indicators, inspection methods, and qualification criteria for each production process. Simultaneously, process documents and operation guidelines are embedded in the ZQ-MES system in electronic format. When production personnel operate equipment, the system provides real-time prompts on relevant process requirements and operation specifications, ensuring that the production process is strictly executed in accordance with standards, thereby guaranteeing product quality from the source.

Real-time dynamic process monitoring

The ZQ-MES system conducts real-time monitoring of the production process, displaying the real-time status of the production site through a visual interface. By utilizing information obtained from data collection, it conducts real-time monitoring and analysis of key process parameters and quality indicators. Once any deviation from the standard range or abnormal situation is detected, the system immediately issues an early warning message. Additionally, the system can monitor the operating status of production equipment, predict equipment failures, and arrange maintenance in advance to avoid quality issues caused by equipment failures. Furthermore, the ZQ-MES system enables real-time tracking of production progress, promptly identifying delays or bottlenecks in the production process, taking corresponding measures to make adjustments, ensuring the continuity and stability of the production process, and thus guaranteeing product quality.

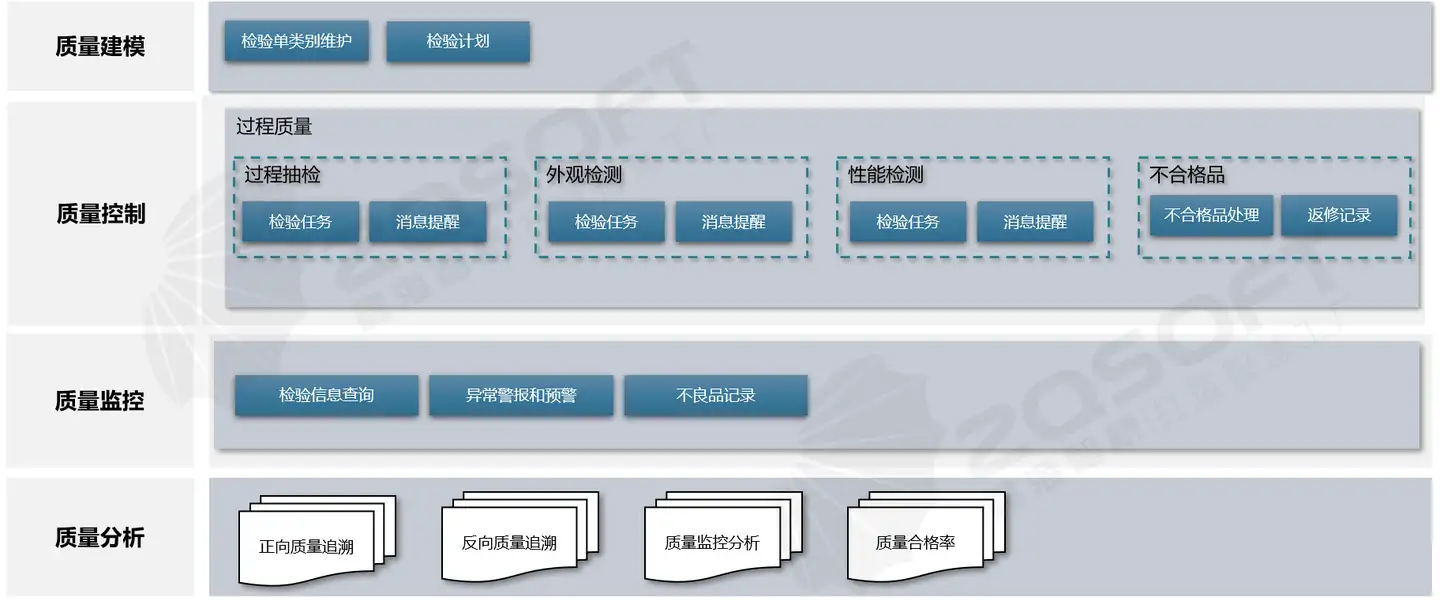

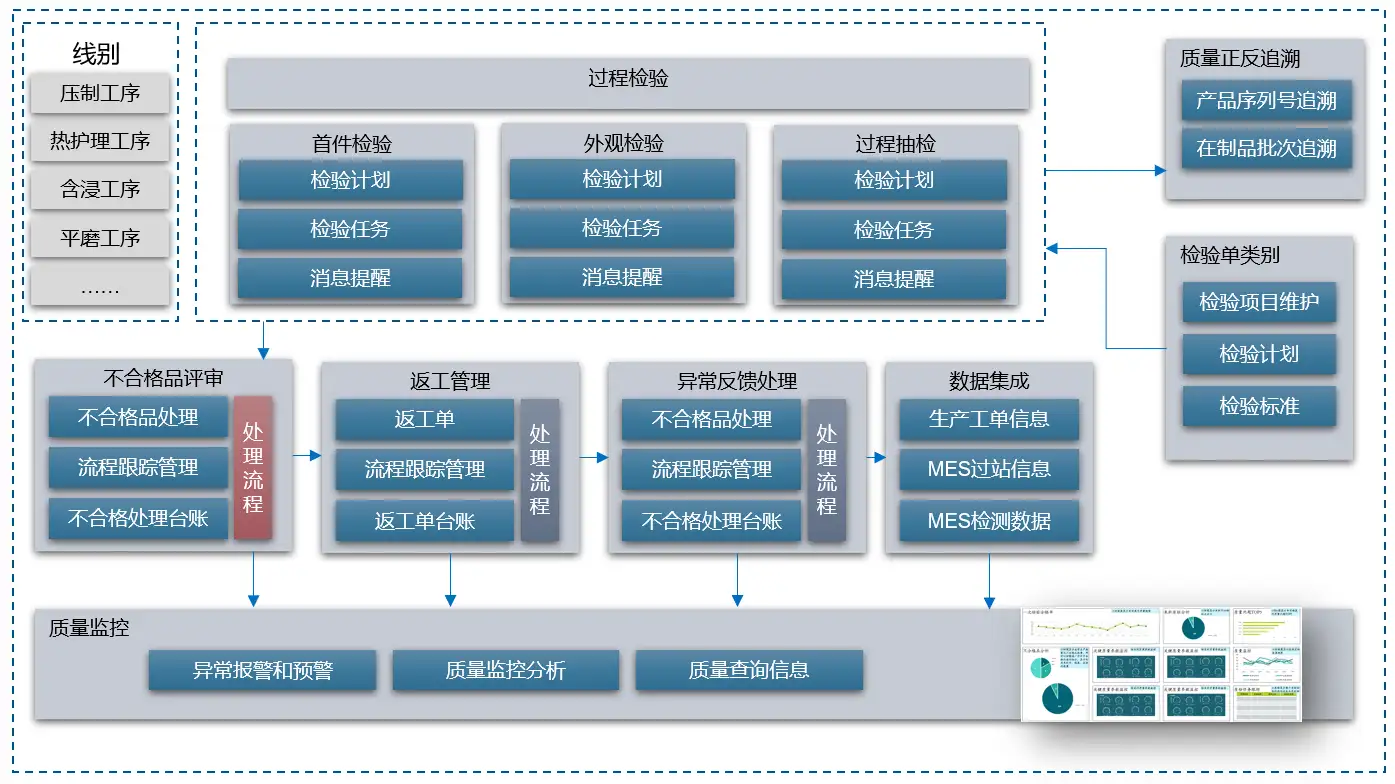

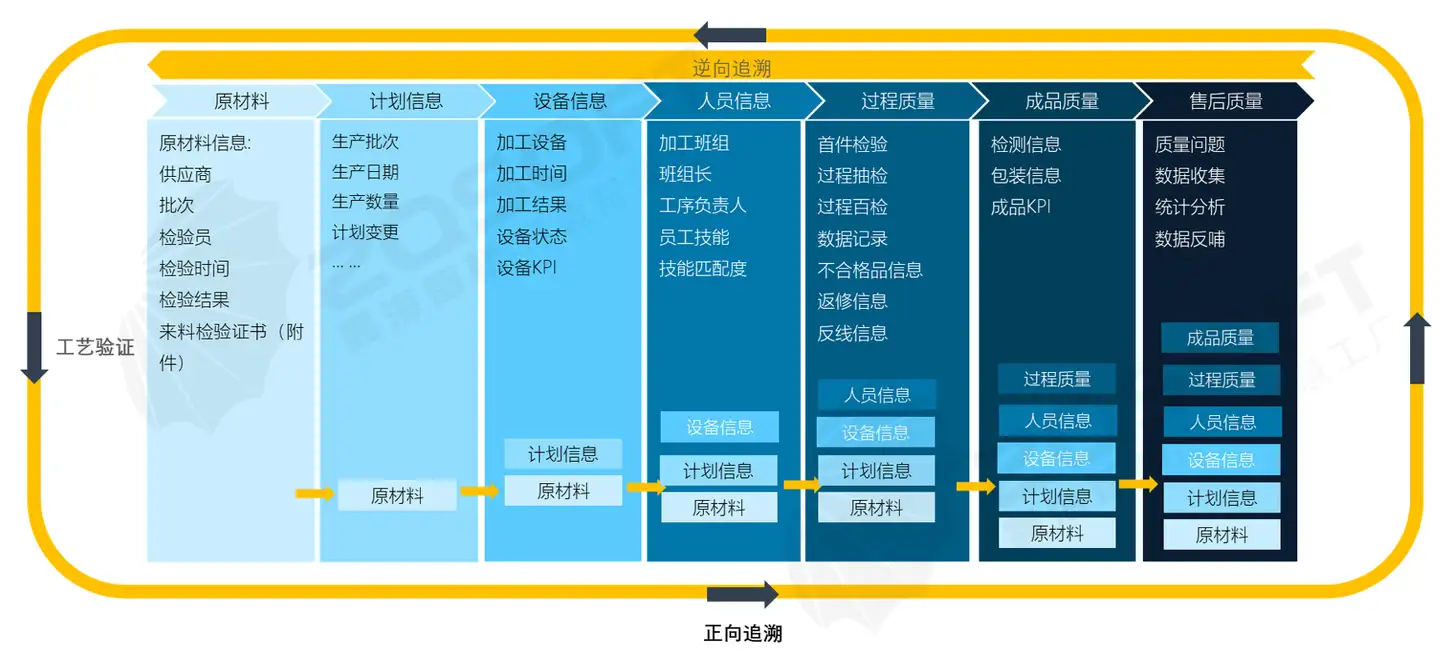

Conduct comprehensive quality inspection and traceability

At key nodes in the production process, ZQ-MES will automatically trigger the quality inspection process. Inspectors can access inspection tasks and inspection standards in the ZQ-MES system through handheld terminals or workshop workstations, conduct spot checks or full inspections on products, and enter the inspection results into the system in real time. The system automatically judges the inspection results based on the inspection standards. For non-conforming products, the ZQ-MES system will record detailed information such as the reason for non-conformity, batch information, and production process, and perform isolation processing. At the same time, the ZQ-MES system has established a comprehensive product quality traceability system. Through correlation analysis of various data collected during the production process, it can quickly trace back to information such as the raw material batch, production equipment, operators, and production time of the product. In the event of a quality issue, the root cause can be accurately identified in a timely manner, and effective corrective and preventive measures can be taken to prevent the recurrence of the problem.

The ZQ-MES system achieves comprehensive and precise control over the quality of the production process through a series of measures, including establishing a data collection and integration system, formulating quality standards and process specifications, implementing real-time process monitoring, conducting quality inspection and traceability, performing quality analysis and improvement, and strengthening personnel training. For instance, the cloud MES system on Assembly Line B of an engine factory in Jinan continuously integrates new technologies and combines them with automated identification and detection technology to monitor engine assembly quality in real time, further enhancing the level of intelligence in quality control. This provides strong support for the enterprise to improve product quality and enhance market competitiveness.

[ZQSOFT, creating new value for customers]

Smart manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing corporate competitiveness. Against this backdrop, ZQSOFT, with its profound technical accumulation and rich industry experience, continues to provide customers with leading IoT technology, smart manufacturing solutions, and MES/MOM/APS systems.

As a technological leader in the industry, ZQSOFT continuously promotes the deep integration of digital transformation and intelligent manufacturing, committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of 'innovation-driven, intelligent manufacturing', helping our customers stand out in the fierce market competition and stay at the forefront of industry development.