In recent years, the tire industry has accelerated the upgrading of digitalization and intelligence. How to achieve efficient collaborative production, quality traceability, and real-time equipment monitoring has become the key to the transformation of manufacturing enterprises. ZQSOFT has been deeply engaged in tire manufacturing for many years, and has tailored intelligent manufacturing system solutions for many tire enterprises in Vietnam, Thailand, Morocco and other places, covering core modules such as MES, APS, equipment interconnection, quality traceability, etc., to help customers significantly improve management efficiency and market competitiveness.

1、 Customer Challenge: Production Collaboration Difficulties under Complex Process Flow

The tire manufacturing process involves multiple stages such as mixing, rolling, molding, and vulcanization, and requires extremely high equipment linkage and data consistency. Many clients generally face the following difficulties before project initiation:

Serious data silos: scattered planning, production, and quality inspection information, lacking a unified management platform;

Frequent manual intervention: relying on experience scheduling, low production efficiency, slow response to changes;

Non traceable quality: lack of complete product history and process data records;

Equipment status is opaque: production abnormalities cannot be alerted in a timely manner, affecting delivery cycles.

2、 Customized solution: an intelligent manufacturing platform based on the characteristics of the tire industry

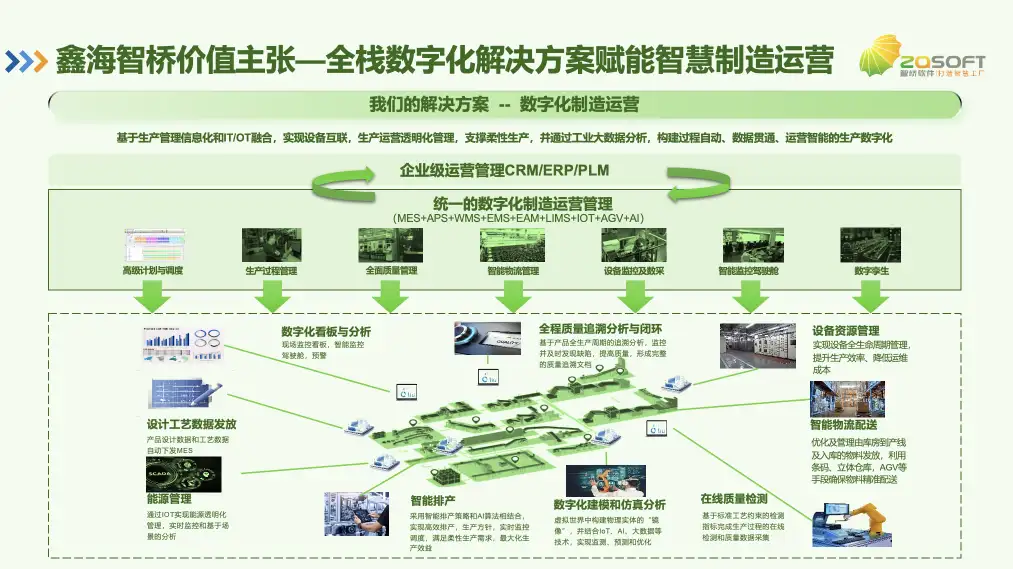

In view of the complex process and strict quality standards in the tire industry, ZQSOFT has formed a mature intelligent manufacturing system architecture based on the project implementation experience, including the following core capabilities:

1). MES Manufacturing Execution System

Realize visual control of the entire process from order placement to production execution, automatically collect key process data, and achieve one tire per record.

2). APS Advanced Planning and Scheduling System

Automatically generate the optimal production schedule based on equipment capacity, material status, and order priority to improve equipment utilization and reduce changeover losses.

3). Equipment networking and status monitoring

Connect core equipment such as mixers and vulcanizers to the platform, monitor the real-time operation status of the equipment, and achieve shutdown warning and data closure.

4). QMS Quality Management Module

Realize the collection and analysis of quality data throughout the entire process from raw materials to finished products, forming a closed-loop traceability chain for product quality.

3、 Overseas project landing results: data-driven, efficient operation

In a large tire factory project in Vietnam, the ZQSOFT team completed system customization, on-site deployment and operation and maintenance support. After the system runs stably:

Production efficiency increased by 22%, automatic scheduling reduced manual coordination;

The yield rate has increased by nearly 8%, and the abnormal warning mechanism has intervened in problem processes in a timely manner;

The data collection coverage rate reaches over 95%, achieving closed-loop control throughout the entire process;

Customer satisfaction has significantly improved, and we have been praised by customers as an efficient system partner close to the front line of the factory.

Similar achievements are still being replicated in projects such as Thailand and Morocco, and the system supports multilingual interfaces and overseas time zone configurations to meet the operational needs of international customers.

4. Focusing on industry scenarios, empowering global tire manufacturing enterprises

Different from the general-purpose system, ZQSOFT intelligent manufacturing solution deeply integrates the process, management and quality characteristics of the tire manufacturing industry, with high adaptability and scalability. By continuously serving customers from multiple locations, the company has accumulated valuable practical experience and can quickly respond to customized needs in the digital construction process of tire enterprises.

In the future, ZQSOFT will continue to be customer value oriented, provide more tire manufacturing enterprises with reliable, efficient and intelligent system solutions, and work together towards a new era of industrial digitalization.

[ZQSOFT. Create new value for customers]

Intelligent manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing enterprise competitiveness. In this context, ZQSOFT continues to provide customers with leading Internet of Things technology, intelligent manufacturing solutions, MES/MOM/APS systems, etc. with its profound technology accumulation and rich industry experience.

As a technology leader in the industry, ZQSOFT has continuously promoted the deep integration of digital transformation and intelligent manufacturing, and is committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of "innovation driven, intelligent manufacturing", helping customers stand out in fierce market competition and stay at the forefront of industry development.