In the production chain of manufacturing, the quality of raw materials is the cornerstone that determines the final product quality, and incoming inspection is the core means of controlling this critical link. The Quality Management System (QMS), with its advanced management philosophy and digital technology, has reshaped the incoming inspection process and brought significant benefits to enterprises.

(1) Development of Inspection Standards and Plans

In ZQ-QMS, enterprises can flexibly set detailed incoming inspection standards based on product design requirements, industry standards, and customer needs. These standards cover multidimensional indicators such as the physical and chemical properties, size specifications, and appearance quality of raw materials. Based on the inspection standards, the system will automatically generate an inspection plan in conjunction with the purchase order information, including inspection batches, sampling plans, inspection items, and inspection personnel arrangements, to ensure that the inspection work is carried out in an orderly manner.

(2) Inspection execution and data collection

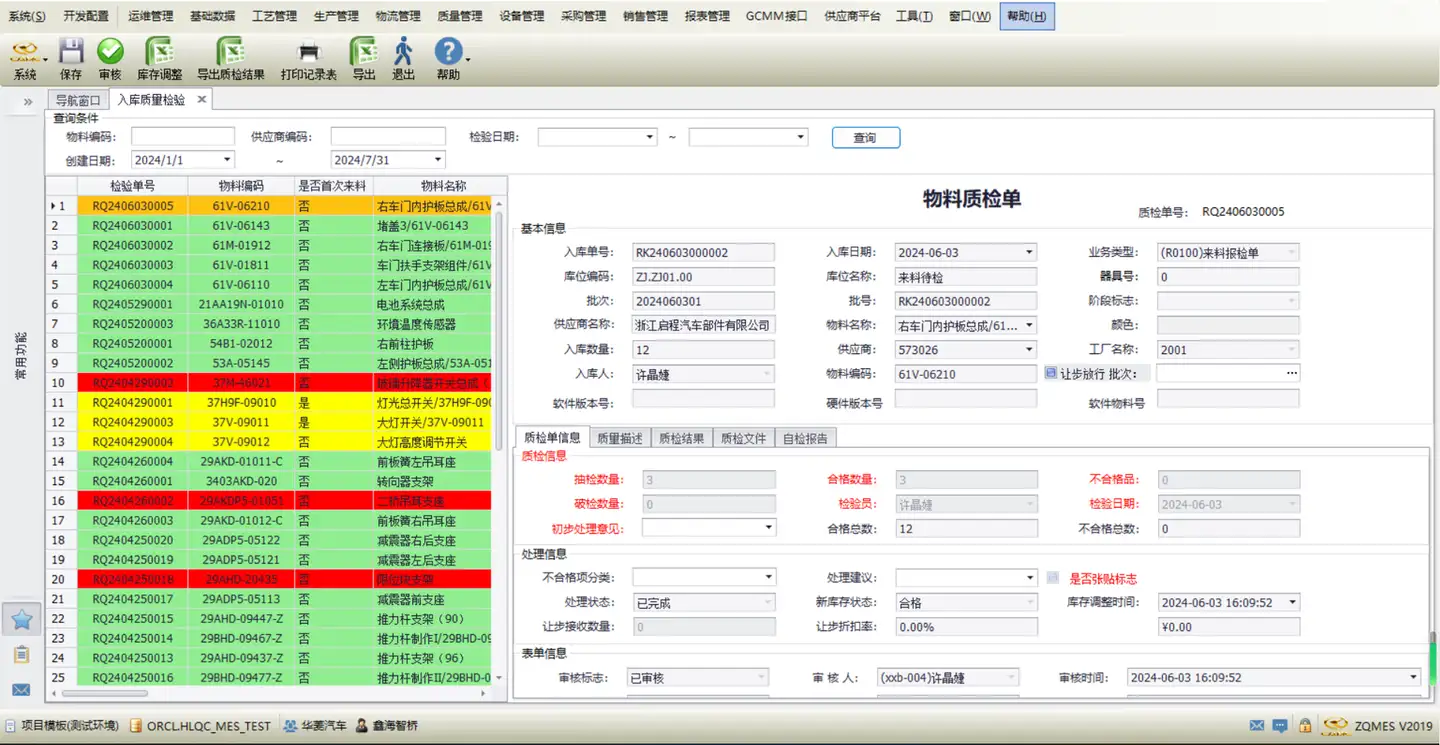

After the raw materials arrive, the inspectors operate according to the inspection plan generated by ZQ-QMS. During the inspection process, the system supports multiple data collection methods. For inspection items that can be completed through automated detection equipment, such as using a spectrometer to detect the composition of metal materials, the system can be directly connected to the equipment to automatically collect detection data; For items that require manual inspection, such as appearance inspection, inspectors can input the inspection results into the system through handheld terminals or PC terminals. The system will also perform real-time verification on the inspection data to avoid data entry errors. For example, when the entered dimensional data exceeds the preset tolerance range, the system will automatically prompt the inspector to conduct a review.

(3) Judgment and Handling of Inspection Results

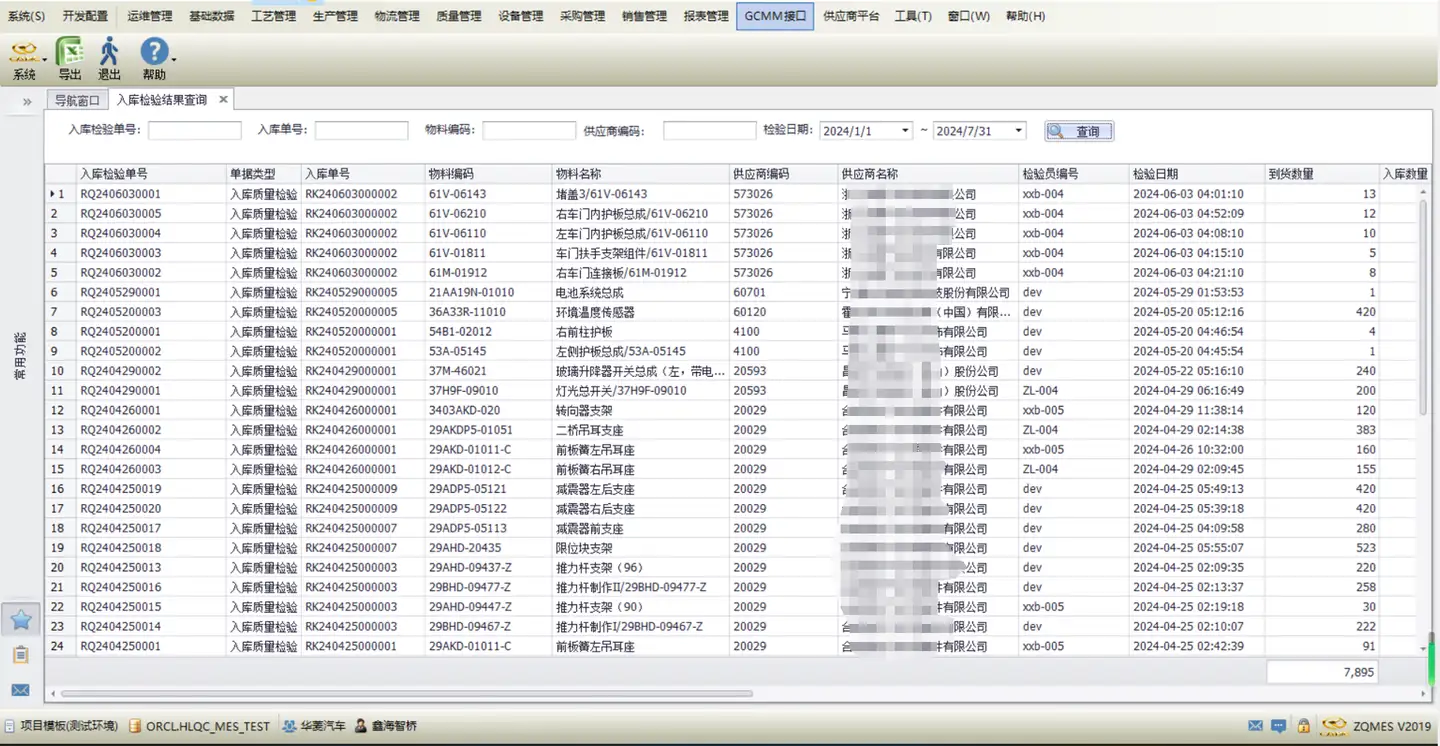

ZQ-QMS automatically analyzes and judges the collected inspection data based on preset inspection standards. If all indicators of the raw materials meet the standards, the system will automatically generate a qualified report, update inventory information, and trigger the subsequent warehousing process; If there is a non conformance situation, the system will immediately issue an alert and generate a non conformance report, detailing the non conformance items, reasons for non conformance, and other information. At the same time, the system will promptly provide feedback on non-conforming information to the procurement department and suppliers, and initiate the non-conforming product handling process. Enterprises can choose to return goods, accept concessions, or require suppliers to make corrections according to their actual situation. The entire process will be recorded in the system for easy traceability and management.

Hualing Group cleverly embeds the ZQ-QMS incoming inspection module into the MES system, combining strict incoming inspection from the source of raw materials to reject unqualified raw materials and ensure product quality from the source. This effectively reduces production rework, product scrapping, and other situations caused by raw material quality issues, and lowers production risks.

[ZQSOFT. Create new value for customers]

Intelligent manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing enterprise competitiveness. In this context, ZQSOFT continues to provide customers with leading Internet of Things technology, intelligent manufacturing solutions, MES/MOM/APS systems, etc. with its profound technology accumulation and rich industry experience.

As a technology leader in the industry, ZQSOFT has continuously promoted the deep integration of digital transformation and intelligent manufacturing, and is committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of "innovation driven, intelligent manufacturing", helping customers stand out in fierce market competition and stay at the forefront of industry development.