In the current booming development of the new energy industry, the battery assembly industry, as a key link, continues to see an increase in market demand. However, battery products have extremely high requirements for safety, stability, and consistency. Any quality negligence in any production process can lead to serious safety accidents or performance issues. Therefore, introducing advanced quality management system (QMS) has become a key measure for the industry to enhance competitiveness and ensure product quality.

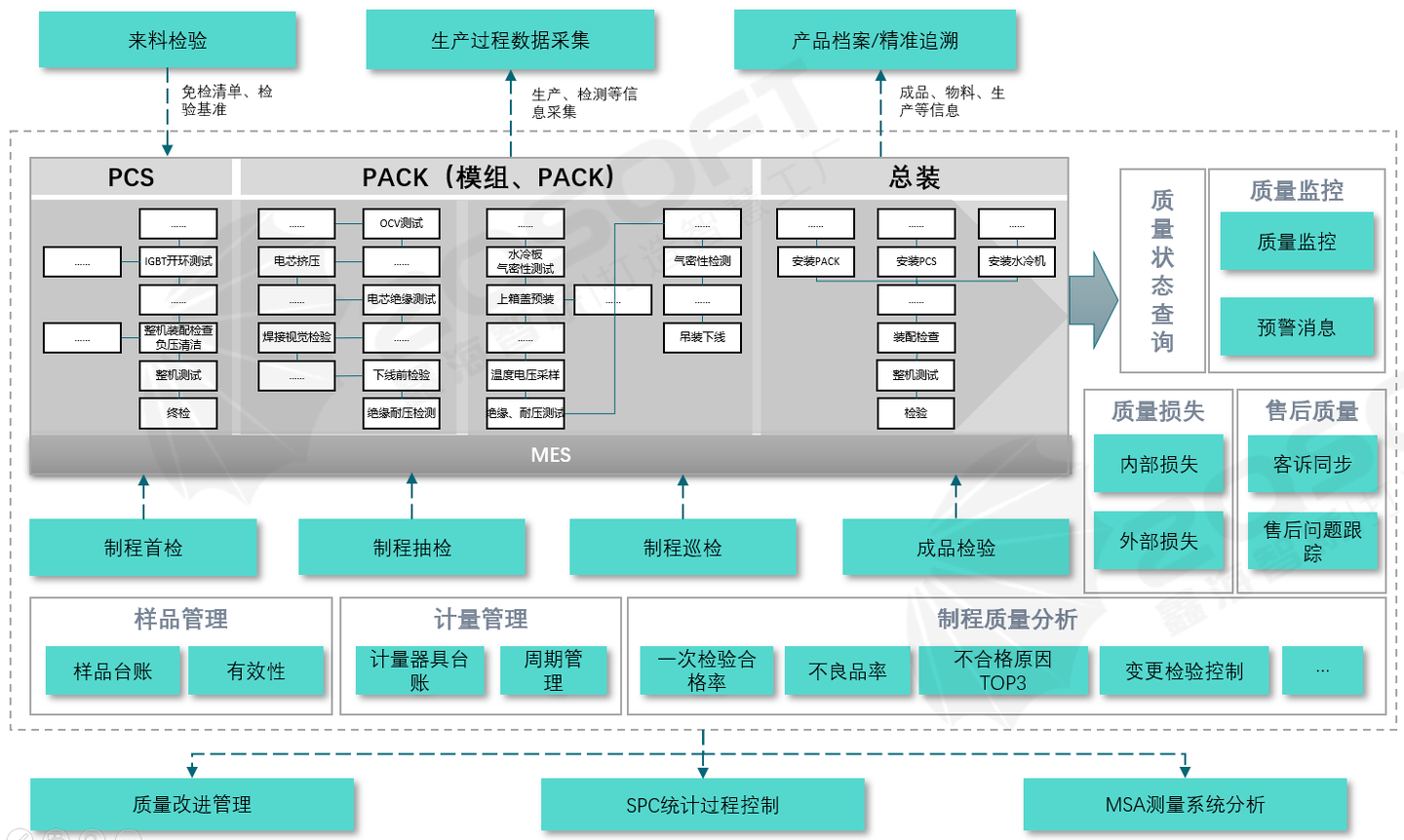

ZQ-QMS combines with a battery assembly factory in Liuzhou to achieve real-time control of various methods such as incoming material nodes, process nodes, finished product nodes, and quality analysis, to ensure the quality of battery assembly.

Raw material inspection

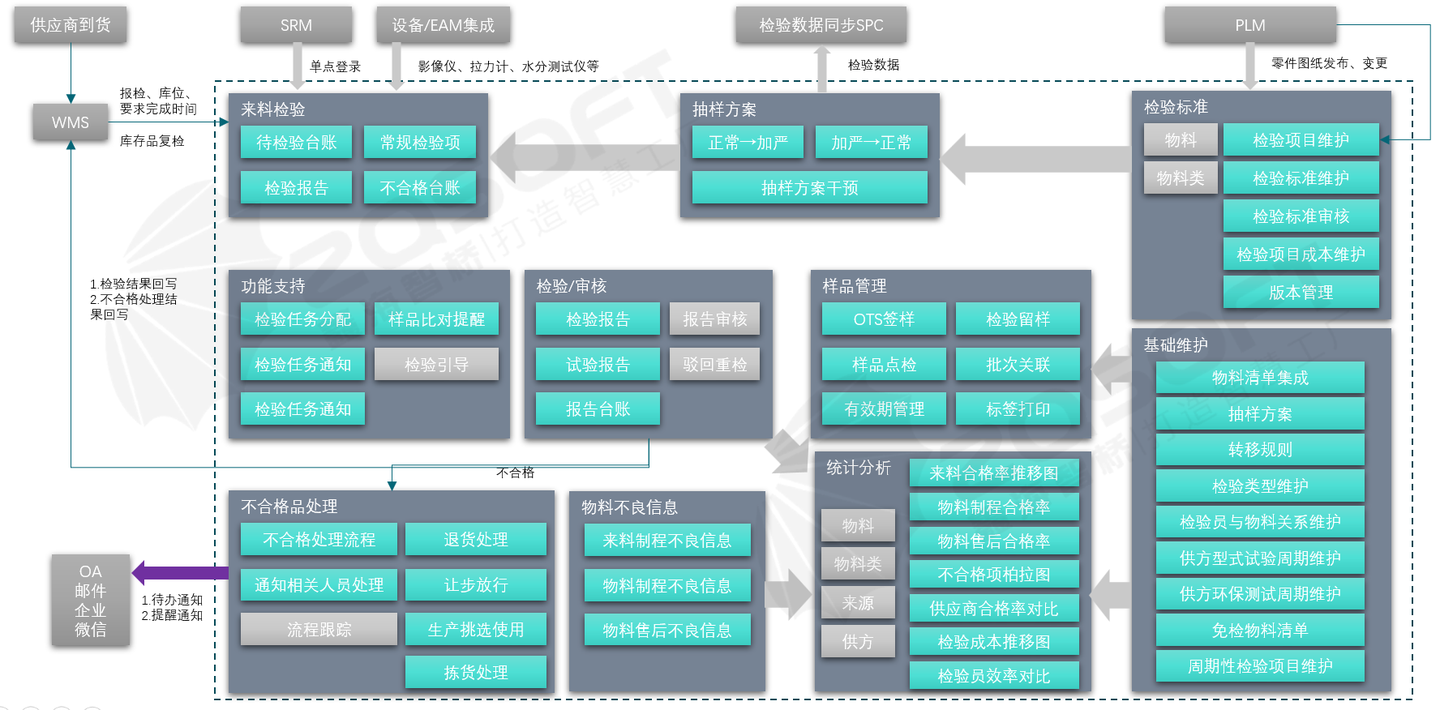

Strictly control the quality of incoming materials: Battery assembly involves various raw materials, such as battery cells, positive and negative electrode materials, separators, electrolytes, etc. ZQ-QMS can record and manage detailed supplier information, batch numbers, inspection reports, etc. for each batch of raw materials. By setting inspection standards and processes, the system can automatically remind inspectors to inspect raw materials in terms of appearance, size, performance, etc., ensuring that only raw materials that meet quality requirements can enter the production process and guarantee product quality from the source.

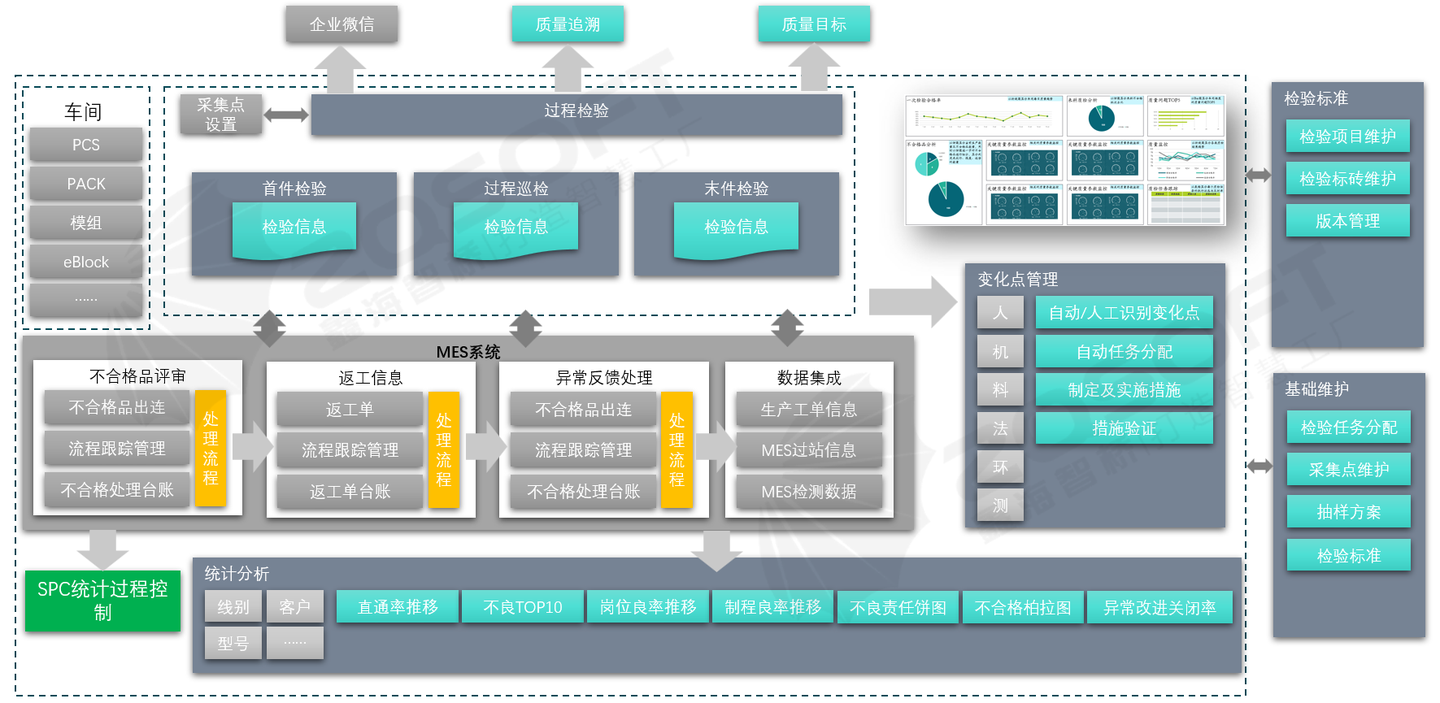

process control

During the battery assembly process, ZQ-QMS uses barcode, QR code and other technologies to uniquely identify each battery component and finished product. In each production process, the system automatically identifies material and product information to prevent errors, omissions, and other issues from occurring. At the same time, the system records all operational information of each product during the production process, including operators, equipment, production time, process parameters, etc., to achieve full traceability of product quality. Once a quality problem occurs, the problem link and cause can be quickly identified, targeted measures can be taken to solve it, and relevant batches of products can be effectively processed.

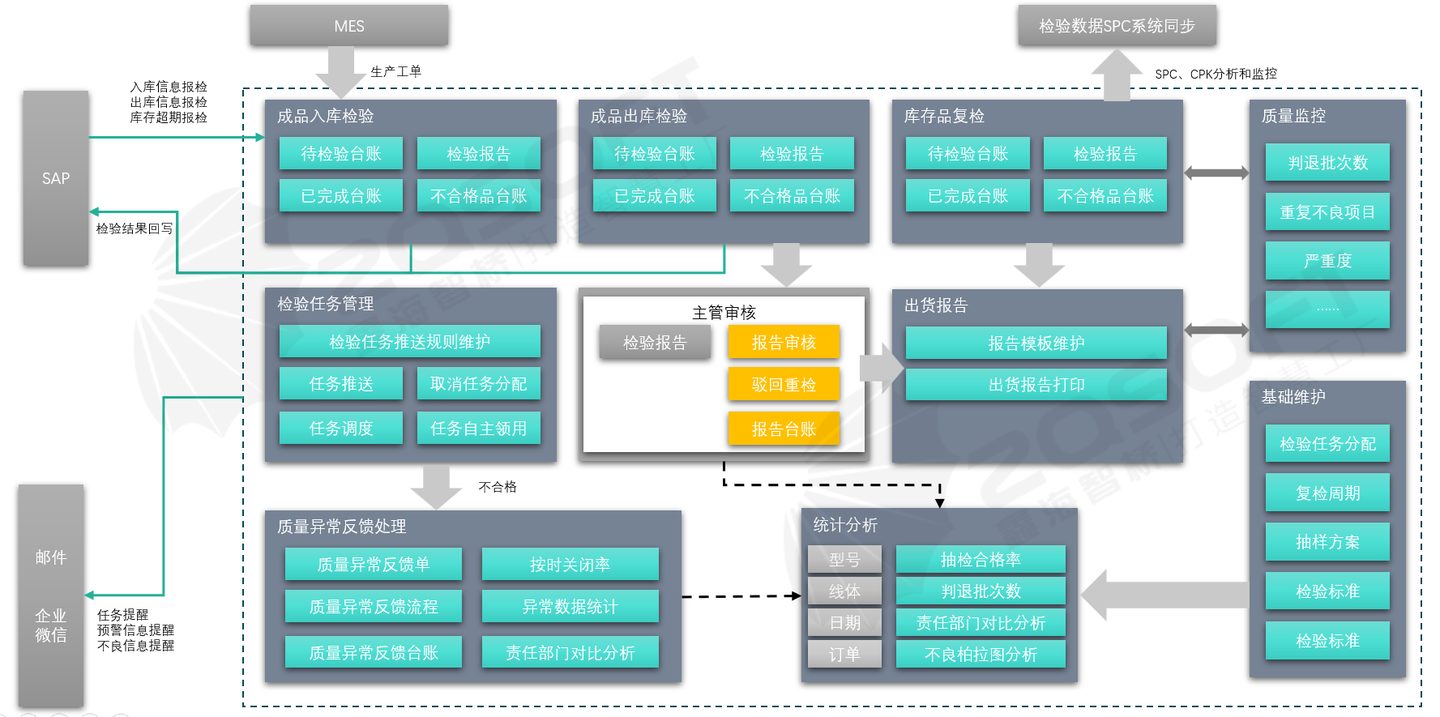

Finished product inspection and testing

Performance testing management: After the battery assembly is completed, multiple performance tests need to be conducted on the finished battery, such as capacity testing, charge and discharge efficiency testing, internal resistance testing, safety performance testing, etc. ZQ-QMS can be integrated with testing equipment to automatically collect test data and compare it with preset qualification standards. For products that fail the test, the system automatically records the non-conforming items and data for subsequent analysis of the reasons and rework processing. At the same time, the system conducts statistical analysis on the performance data of finished batteries, generates quality reports, and helps enterprises grasp the dynamics of product quality and timely discover potential quality problem trends.

Reliability verification: Through ZQ-QMS, enterprises can develop reliability verification plans and conduct long-term aging tests, cyclic charge and discharge tests, high and low temperature environmental tests, etc. on battery products. The system records the data and results during the testing process, evaluates the reliability and lifespan of the product, and provides a basis for product design improvement and quality enhancement.

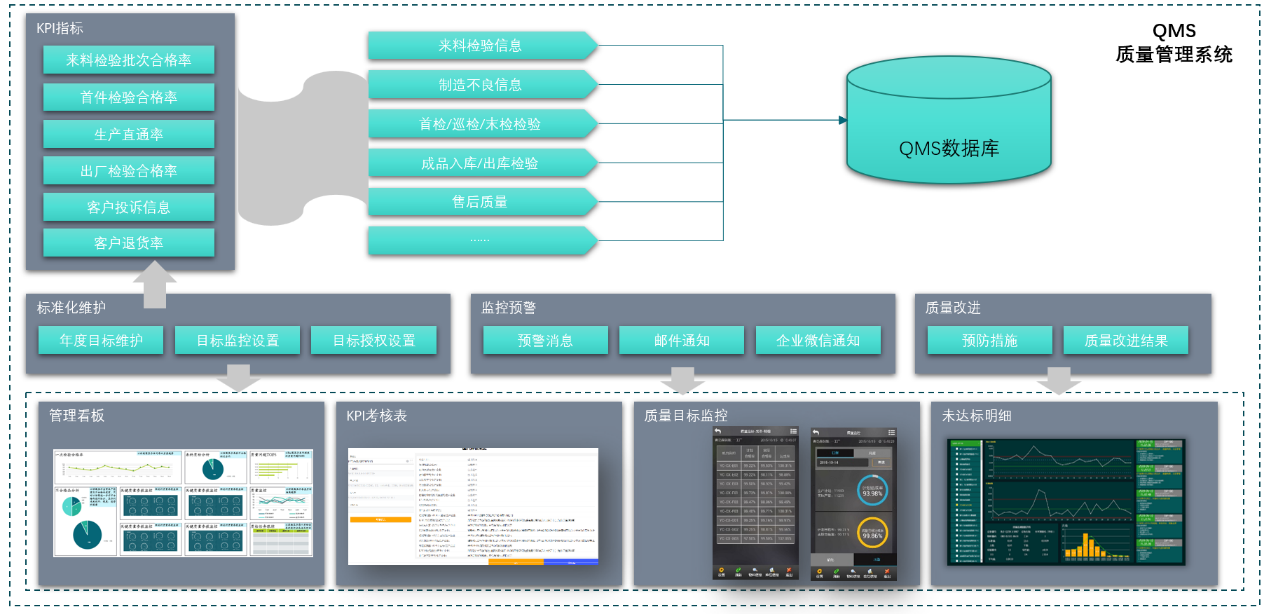

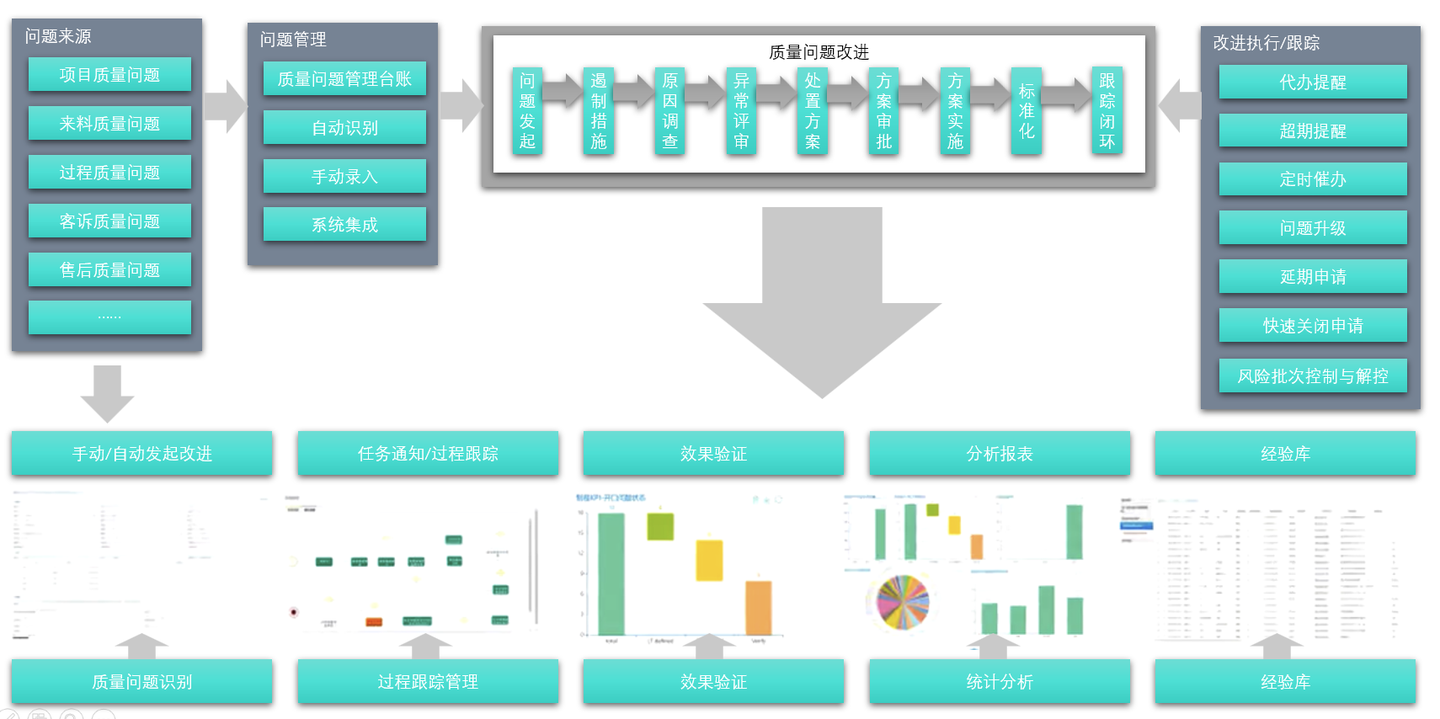

Quality data analysis and continuous improvement

ZQ-QMS has accumulated a large amount of quality data, covering various aspects such as raw materials, production processes, and finished product inspections. By utilizing the data analysis function of the system, enterprises can conduct in-depth mining and analysis of this data, identify key factors and potential patterns of quality issues. Analyze data fluctuations in the production process using Statistical Process Control (SPC) technology to determine if there are any unstable or abnormal conditions in the process; Identify the relationship between raw material quality and finished product performance through correlation analysis, providing reference for raw material procurement and quality control.

Based on the analysis results of quality data, support enterprises in formulating and implementing continuous improvement measures. The system can assign improvement tasks to relevant departments and personnel, and track the progress and effectiveness of the improvements. By continuously optimizing production processes, improving quality management systems, and strengthening employee training, we aim to continuously improve product quality and production efficiency, reduce quality costs, and enhance our competitiveness in the battery assembly industry.

[ZQSOFT, creating new value for customers]

Smart manufacturing, as the key to industrial upgrading, has become an important engine for promoting industry development and enhancing corporate competitiveness. Against this backdrop, ZQSOFT, with its profound technical accumulation and rich industry experience, continues to provide customers with leading IoT technology, smart manufacturing solutions, and MES/MOM/APS systems.

As a technological leader in the industry, ZQSOFT continuously promotes the deep integration of digital transformation and intelligent manufacturing, committed to providing the most competitive solutions for the global manufacturing industry. We will continue to uphold the core concept of 'innovation-driven, intelligent manufacturing', helping our customers stand out in the fierce market competition and stay at the forefront of industry development.